This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

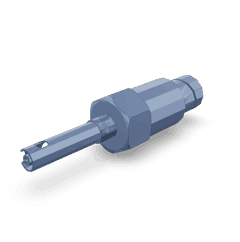

The Cummins 3255823 Fluid Level Sensor is a component designed to monitor fluid levels within commercial trucks. Its role is significant in ensuring the proper operation and maintenance of these vehicles, contributing to their overall efficiency and safety.

Basic Concepts of Fluid Level Sensors

Fluid level sensors are devices that measure the amount of liquid within a system. They operate using various technologies, including float mechanisms, ultrasonic waves, or capacitive methods. In automotive systems, these sensors are vital for monitoring levels of critical fluids such as engine oil, coolant, and fuel. Accurate fluid level monitoring helps prevent engine damage, ensures optimal performance, and enhances safety by avoiding unexpected breakdowns 1.

Purpose of the Cummins 3255823 Fluid Level Sensor

The Cummins 3255823 Fluid Level Sensor is specifically designed to monitor fluid levels in commercial trucks. It plays a role in the truck’s operation by providing real-time data on fluid levels to the vehicle’s electronic control system. This information allows for timely alerts when fluid levels are low, enabling maintenance personnel to address potential issues before they lead to more significant problems 2.

Key Features

The Cummins 3255823 Fluid Level Sensor is characterized by its robust design and high-quality materials, ensuring durability and reliability in demanding environments. It incorporates advanced technological specifications to provide accurate and consistent readings. The sensor is engineered to withstand the harsh conditions often encountered in commercial trucking, including extreme temperatures and vibrations 3.

Benefits of Using the Cummins 3255823 Fluid Level Sensor

Incorporating the Cummins 3255823 Fluid Level Sensor into truck maintenance and operation offers several advantages. It contributes to improved efficiency by ensuring that fluid levels are maintained within the optimal range, which can enhance engine performance and fuel efficiency. Additionally, it plays a role in enhancing safety by providing early warnings of low fluid levels, thereby reducing the risk of engine damage or failure 4.

Installation and Integration

Proper installation and integration of the Cummins 3255823 Fluid Level Sensor within a truck’s system are crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure accurate readings and reliable performance. Integration with the vehicle’s electronic control system allows for seamless monitoring and reporting of fluid levels.

Troubleshooting Common Issues

Common problems associated with fluid level sensors include inaccurate readings, sensor malfunctions, and electrical issues. Troubleshooting steps may involve checking the sensor’s installation, ensuring proper electrical connections, and verifying the sensor’s calibration. Regular inspections and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3255823 Fluid Level Sensor, regular maintenance practices are recommended. These include periodic inspections for signs of wear or damage, cleaning the sensor to remove any debris or contaminants, and verifying its calibration. Adhering to these maintenance tips can help maintain the sensor’s accuracy and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a reputable name in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation. Cummins’ commitment to innovation and quality has solidified its position as a leader in the industry.

Fluid Level Sensor (Part 3255823) Compatibility with Cummins Engines

The Fluid Level Sensor part number 3255823, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This sensor plays a role in monitoring the fluid levels within the engine’s system, ensuring optimal performance and preventing potential damage due to low fluid levels.

Compatibility with QSK50 CM2150 MCRS and QSK60 CM850 MCRS

The Fluid Level Sensor 3255823 is specifically engineered to fit seamlessly with the QSK50 CM2150 MCRS and QSK60 CM850 MCRS engines. These engines are part of Cummins’ extensive lineup, known for their reliability and efficiency in various industrial applications.

- QSK50 CM2150 MCRS: This engine model benefits from the precise fluid level monitoring provided by the 3255823 sensor. The sensor’s integration ensures that the engine operates within the optimal fluid parameters, enhancing longevity and performance.

- QSK60 CM850 MCRS: Similarly, the QSK60 CM850 MCRS engine is designed to work in conjunction with the 3255823 Fluid Level Sensor. This compatibility ensures that the engine’s fluid levels are consistently monitored, preventing issues related to fluid deficiencies.

The Fluid Level Sensor 3255823 is a component for maintaining the health and efficiency of these engines, providing real-time data that helps in proactive maintenance and operational efficiency.

Role of Part 3255823 Fluid Level Sensor in Engine Systems

The Part 3255823 Fluid Level Sensor is an integral component in maintaining the optimal performance and safety of engine systems. This sensor is designed to accurately measure the fluid levels within the engine, specifically focusing on the oil level.

Integration with Engine Components

-

Oil Pan: The sensor is typically installed in the oil pan, where it directly interacts with the oil. Its primary function is to detect the oil level and ensure it remains within the specified range. This is essential for lubricating the engine’s moving parts and preventing damage due to insufficient lubrication.

-

Engine Control Module (ECM): The fluid level sensor sends real-time data to the ECM. The ECM uses this information to make adjustments to the engine’s operation, ensuring that it runs efficiently and safely. For instance, if the oil level is low, the ECM can trigger a warning light on the dashboard to alert the driver.

-

Oil Gauge: In many vehicle designs, the sensor’s data is also transmitted to the oil gauge on the dashboard. This allows the driver to visually monitor the oil level, providing an additional layer of awareness and enabling timely top-ups or maintenance checks.

-

Overall System Monitoring: Beyond just the oil level, the sensor contributes to the overall health monitoring of the engine. It helps in diagnosing potential issues early, such as oil leaks or consumption, which could indicate more significant problems like worn piston rings or valve seals.

Conclusion

In summary, the Cummins 3255823 Fluid Level Sensor plays a role in the engine system by ensuring that the oil level is maintained at optimal levels, thereby supporting the engine’s longevity and performance. Its integration with various engine components ensures comprehensive monitoring and timely alerts, contributing to the overall efficiency and safety of commercial trucks.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Cummins Inc. Service Manual (5504562).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.