3687930

Nitrogen Oxide Sensor

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Nitrogen Oxide Sensor 3687930 by Cummins is a specialized component designed for use in heavy-duty truck engines. Its purpose is to monitor nitrogen oxide (NOx) emissions, which are a significant concern in the automotive industry due to their environmental impact. This sensor plays a role in ensuring that truck engines operate within regulatory emission standards while maintaining efficient performance.

Basic Concepts of Nitrogen Oxide Sensors

Nitrogen oxides (NOx) are a group of gases formed during the combustion process in diesel engines. They are produced when nitrogen and oxygen in the air react under high temperatures and pressures. NOx emissions contribute to air pollution and can have adverse effects on both the environment and human health. Nitrogen oxide sensors are employed to monitor these emissions, providing real-time data to the engine management system. These sensors typically utilize electrochemical cells or infrared technology to measure NOx levels accurately 1.

Purpose of the 3687930 Nitrogen Oxide Sensor

This part is integral to the operation of heavy-duty trucks. It provides continuous monitoring of NOx emissions, allowing the engine management system to make necessary adjustments to fuel injection and exhaust gas recirculation (EGR) rates. This ensures that the engine operates efficiently while adhering to emission standards. By maintaining optimal emission levels, the sensor contributes to both environmental protection and engine performance.

Key Features

The 3687930 Nitrogen Oxide Sensor is characterized by its robust design and high-quality construction materials. It incorporates advanced sensor technology that enhances its accuracy and durability. The sensor is engineered to withstand the harsh conditions present in diesel engine environments, ensuring reliable performance over time. Its design allows for easy integration into various truck models, facilitating straightforward installation and maintenance.

Benefits of Using the 3687930 Nitrogen Oxide Sensor

Incorporating this Cummins part into heavy-duty trucks offers several advantages. It enables improved emission control by providing precise NOx measurements, which allows the engine management system to optimize combustion processes. This results in enhanced engine efficiency and reduced fuel consumption. Additionally, the sensor aids in compliance with stringent environmental regulations, helping fleet operators avoid penalties and maintain a positive environmental footprint 2.

Installation and Integration

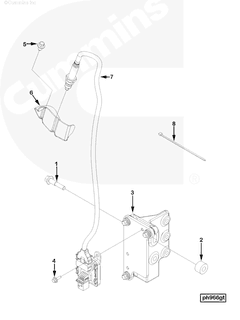

Proper installation of the 3687930 Nitrogen Oxide Sensor is crucial for its effective operation. It should be installed in accordance with the manufacturer’s guidelines to ensure accurate readings and reliable performance. Integration into various truck models may require specific considerations, such as compatibility with the engine management system and exhaust system design. Following the recommended installation procedures will help ensure the sensor functions correctly within the engine system.

Troubleshooting and Maintenance

Common issues associated with nitrogen oxide sensors include inaccurate readings and sensor failure due to contamination or wear. Troubleshooting steps may involve checking electrical connections, verifying sensor placement, and ensuring the exhaust system is free from obstructions. Regular maintenance, such as cleaning the sensor and inspecting for damage, can help prolong its lifespan and ensure accurate functioning. Adhering to the manufacturer’s maintenance schedule is recommended to maintain sensor performance.

Regulatory Compliance and Emission Standards

The 3687930 Nitrogen Oxide Sensor plays a role in helping heavy-duty trucks meet various emission standards and regulations. Accurate NOx monitoring is vital for legal and environmental compliance, as it ensures that emissions remain within permissible limits. By providing real-time data on NOx levels, the sensor enables the engine management system to make adjustments that keep the engine in compliance with current regulations, thereby supporting both legal adherence and environmental stewardship.

Technological Advancements in Nitrogen Oxide Sensing

Recent technological advancements in nitrogen oxide sensors have focused on improving accuracy, durability, and integration with engine management systems. Innovations such as enhanced sensor materials, improved electrochemical cells, and more sophisticated signal processing algorithms have contributed to these advancements. These improvements ensure that nitrogen oxide sensors can provide more reliable and precise measurements, even in the challenging environments of diesel engines 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the automotive and heavy-duty truck industry. The company is committed to innovation and environmental sustainability, continually developing advanced technologies to improve engine efficiency and reduce emissions. Cummins’ dedication to quality and performance is evident in its wide range of products, including the 3687930 Nitrogen Oxide Sensor.

Nitrogen Oxide Sensor Compatibility with Cummins Engines

The Nitrogen Oxide Sensor, part number 3687930, manufactured by Cummins, is designed to be compatible with a variety of Cummins engine models. Below is a detailed overview of its compatibility with the specified engines:

ISX12 CM2350 X102 and ISX15 CM2350 X101

The ISX12 CM2350 X102 and ISX15 CM2350 X101 engines both feature the same base engine architecture, allowing the 3687930 sensor to fit seamlessly. These engines are known for their robust performance and efficiency, and the sensor plays a crucial role in maintaining compliance with emissions regulations.

QSX15 CM2350 X105

The QSX15 CM2350 X105 engine is another variant that is compatible with the 3687930 Nitrogen Oxide Sensor. This engine is designed for heavy-duty applications, and the sensor ensures that it operates within the required emissions standards.

X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B

The X15 series engines, specifically the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, also support the use of the 3687930 sensor. These engines are engineered for versatility and reliability, and the sensor is integral to their emissions control systems.

Summary

The 3687930 Nitrogen Oxide Sensor is a versatile component that fits well with the ISX12 CM2350 X102, ISX15 CM2350 X101, QSX15 CM2350 X105, X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B engines. Its compatibility with these engines ensures that they can meet stringent emissions standards while maintaining optimal performance.

Role of Part 3687930 Nitrogen Oxide Sensor in Engine Systems

This part is an integral component within modern engine systems, designed to monitor and regulate emissions. This sensor is strategically positioned in the exhaust system, where it measures the concentration of nitrogen oxides (NOx) produced during combustion.

Interaction with the Engine Control Unit (ECU)

The data collected by the Nitrogen Oxide Sensor is transmitted to the Engine Control Unit (ECU). The ECU uses this information to adjust various engine parameters, such as fuel injection timing and air-fuel ratio, to ensure that emissions remain within acceptable limits. This interaction is vital for maintaining optimal engine performance while minimizing environmental impact.

Contribution to the Exhaust Gas Recirculation (EGR) System

The Nitrogen Oxide Sensor also plays a significant role in the Exhaust Gas Recirculation (EGR) system. By providing real-time data on NOx levels, the sensor allows the ECU to fine-tune the EGR valve operation. This ensures that the correct amount of exhaust gas is recirculated back into the intake manifold, which helps to reduce NOx emissions without compromising engine efficiency.

Support for the Catalytic Converter

In conjunction with the catalytic converter, the Nitrogen Oxide Sensor enhances the overall emission control strategy of the engine. The sensor’s feedback loop enables the ECU to make necessary adjustments to the air-fuel mixture, ensuring that the catalytic converter operates under optimal conditions. This synergy between the sensor and the catalytic converter is essential for achieving significant reductions in harmful emissions.

Enhancement of the Oxygen Sensor Functionality

The Nitrogen Oxide Sensor complements the functionality of the oxygen sensor by providing additional data points related to NOx emissions. This comprehensive monitoring allows the ECU to make more informed decisions regarding fuel delivery and combustion timing, leading to improved overall engine performance and reduced environmental impact.

Integration with On-Board Diagnostics (OBD)

Finally, the Nitrogen Oxide Sensor is a key component in the On-Board Diagnostics (OBD) system. It provides continuous monitoring of NOx levels, allowing the OBD system to detect any anomalies or malfunctions in the emission control system. This proactive monitoring helps to ensure that the engine system remains compliant with emission regulations and operates efficiently over its lifespan.

Conclusion

The 3687930 Nitrogen Oxide Sensor by Cummins is a critical component in the emission control systems of heavy-duty trucks. Its accurate monitoring of NOx emissions ensures that engines operate efficiently while meeting stringent regulatory standards. The sensor’s integration with various engine systems, including the ECU, EGR, catalytic converter, and OBD, highlights its importance in maintaining both engine performance and environmental compliance. By utilizing advanced sensor technology and ensuring compatibility with a range of Cummins engines, this part contributes significantly to the overall efficiency and sustainability of heavy-duty truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.