This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

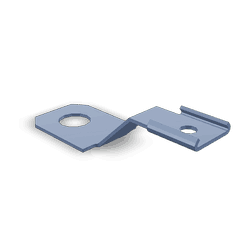

The Cummins 3864187 Sensor Mounting Bracket is a component designed to support and secure sensors in commercial trucks. Its purpose is to ensure that sensors are correctly positioned and remain stable during operation, which is significant for the accurate monitoring and performance of the vehicle 3.

Basic Concepts of Sensor Mounting Brackets

A Sensor Mounting Bracket serves as a structural support for sensors within a vehicle. It facilitates the integration of sensors with other components by providing a stable platform. This ensures that sensors can accurately detect and transmit data without being affected by vibrations or movement 1.

Purpose of the 3864187 Sensor Mounting Bracket

The 3864187 Sensor Mounting Bracket plays a role in the operation of a truck by securely holding sensors in place. This allows sensors to interact effectively with the vehicle’s monitoring system, ensuring that data collected is accurate and reliable. The bracket’s design helps in maintaining the sensors’ alignment and stability, which is crucial for the proper functioning of the truck’s systems 3.

Key Features

The 3864187 Sensor Mounting Bracket is constructed from durable materials, ensuring longevity and resistance to wear. Its design includes features such as precise mounting points and robust construction, which enhance its functionality. These attributes contribute to the bracket’s ability to withstand the rigors of commercial truck operation 2.

Benefits

The 3864187 Sensor Mounting Bracket offers several benefits, including improved sensor stability, which leads to more accurate data collection. Its enhanced durability ensures long-term performance, potentially contributing to overall vehicle efficiency and reliability 3.

Installation Process

To install the 3864187 Sensor Mounting Bracket, begin by identifying the correct location on the truck where the sensor will be mounted. Use the appropriate tools to secure the bracket in place, ensuring it is aligned correctly with the sensor. Follow the manufacturer’s guidelines for tightening bolts to the specified torque, which ensures the bracket is firmly attached without risking damage to the sensor or bracket 3.

Troubleshooting Common Issues

Common problems with Sensor Mounting Brackets may include loose connections or damage from vibrations. To address these issues, regularly inspect the bracket and sensor for signs of wear or misalignment. Tighten any loose bolts and replace any damaged components to maintain the integrity of the sensor system 3.

Maintenance Tips

Regular maintenance of the 3864187 Sensor Mounting Bracket involves checking for signs of wear or corrosion. Cleaning the bracket and ensuring that all connections are secure can help prevent issues. Additionally, monitoring the sensor’s performance can indicate whether the bracket is functioning correctly 3.

Role in Diagnostic Systems

The 3864187 Sensor Mounting Bracket contributes to the diagnostic systems of commercial trucks by ensuring that sensors are accurately positioned. This leads to reliable data collection, which is vital for the diagnostic processes that monitor and maintain the truck’s performance 3.

About Cummins

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and components like the 3864187 Sensor Mounting Bracket, Cummins has established a reputation for excellence and reliability in the market 3.

Cummins Sensor Mounting Bracket 3864187 Compatibility

The Cummins Sensor Mounting Bracket part number 3864187 is designed to fit a variety of Cummins engines, ensuring compatibility across multiple models. Here is a detailed breakdown of the engines with which this bracket is compatible:

Cummins B Series Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B6.7 CM2670 B164C

Cummins L Series Engines

- L8.9 CM2670 L134C

Cummins QSB Series Engines

- QSB4.5 CM850(CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850(CM2850)

- QSB7 CM2880 B117

Cummins QSC Series Engines

- QSC8.3 CM850(CM2850)

Cummins QSL Series Engines

- QSC9 CM2250/QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM850(CM2850)

This bracket is engineered to provide a secure mounting solution for various sensors, ensuring optimal performance and reliability across these engine models 3.

Role of Part 3864187 Sensor Mounting Bracket in Engine Systems

The Part 3864187 Sensor Mounting Bracket is an integral component in the assembly and operation of various engine systems. It provides a secure and stable platform for the attachment of sensors, ensuring accurate readings and reliable performance.

Integration with Engine Control Systems

-

Engine Control Module (ECM) and Engine Control Module Wiring Harness: The Sensor Mounting Bracket facilitates the secure placement of the ECM, which is the brain of the engine’s electronic control system. It ensures that the ECM remains stable and protected, allowing for precise control over engine operations. The wiring harness is also routed and supported by the bracket, minimizing the risk of damage from vibrations or movement.

-

Electronic Control Module (ECM) Plumbing: In systems where the ECM requires fluid connections for cooling or other functions, the Sensor Mounting Bracket helps in organizing and securing these plumbing lines. This ensures that the connections remain intact and function correctly under various operating conditions.

Sensor Attachment and Support

-

Coolant Temperature Sensor and Coolant Level Sensor: These sensors are vital for monitoring the engine’s thermal conditions. The Sensor Mounting Bracket provides a stable base for these sensors, ensuring they are correctly positioned to deliver accurate temperature and level readings. This is essential for maintaining optimal engine performance and preventing overheating.

-

Oil Level Sensor: Similarly, the oil level sensor relies on the Sensor Mounting Bracket for secure attachment. Accurate oil level readings are crucial for engine lubrication and longevity, and the bracket ensures the sensor is correctly aligned and stable.

Support for Air and Fuel Systems

-

Air Compressor and Air Compressor Upfit Kit: The bracket supports the mounting of components related to the air compressor, ensuring that these parts are securely fixed and operate efficiently. This is particularly important in upfit kits where additional air systems are integrated into the engine.

-

Air Intake Connection: Secure mounting of the air intake connection is facilitated by the Sensor Mounting Bracket, ensuring a stable and leak-free connection. This is essential for maintaining the correct air-fuel mixture and engine performance.

Additional Component Support

-

Flywheel Housing Plumbing: The bracket assists in the secure attachment of plumbing lines associated with the flywheel housing, ensuring that these critical connections remain stable and functional.

-

Injector Plumbing: For fuel injection systems, the Sensor Mounting Bracket helps in organizing and securing the injector plumbing, ensuring that fuel lines are correctly positioned and protected from damage.

-

Signal Generating Device: Devices that generate signals for engine control systems are often mounted using this bracket, ensuring they are securely fixed and able to operate under various engine conditions.

-

Starting Motor Mounting: The bracket can also support the starting motor, providing a stable base that ensures reliable engine starts and reduces the risk of mechanical failure.

Conclusion

In summary, the Part 3864187 Sensor Mounting Bracket plays a significant role in the integration and support of various sensors and components within engine systems, ensuring they operate efficiently and reliably 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.