This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3895960 Viscosity Sensor is a specialized component designed to monitor the viscosity of engine oil in commercial trucks. This sensor plays a role in the engine cooling system by providing real-time data on oil viscosity, which is important for maintaining optimal lubrication and performance 1.

Basic Concepts of Viscosity Sensors

Viscosity sensors measure the thickness or resistance to flow of a fluid. In automotive applications, these sensors monitor the viscosity of engine oil. By assessing the oil’s viscosity, the sensor can provide insights into the oil’s condition and the engine’s overall health. This information helps in making informed decisions regarding oil changes and maintenance schedules 2.

Purpose of the Cummins 3895960 Viscosity Sensor

The Cummins 3895960 Viscosity Sensor is integral to the operation of a truck’s engine system. It continuously monitors the viscosity of the engine oil, ensuring that it remains within the optimal range for efficient lubrication. This sensor helps in detecting any deviations in oil viscosity that may indicate contamination, degradation, or the need for an oil change. By providing accurate and timely data, the sensor contributes to maintaining engine performance and longevity.

Key Features

The Cummins 3895960 Viscosity Sensor is characterized by its robust design and high-quality construction materials. It incorporates advanced technological components that enable precise measurement and reporting of oil viscosity. The sensor is engineered to withstand the harsh operating conditions typical of commercial truck engines, ensuring durability and reliability.

Benefits of Using the Cummins 3895960 Viscosity Sensor

Utilizing the Cummins 3895960 Viscosity Sensor offers several advantages. It enhances engine performance by ensuring that the oil viscosity is always optimal, which improves lubrication and reduces wear on engine components. Additionally, it contributes to enhanced fuel efficiency by maintaining the engine in peak condition. The sensor also helps in prolonging the lifespan of engine components by preventing damage caused by improper lubrication.

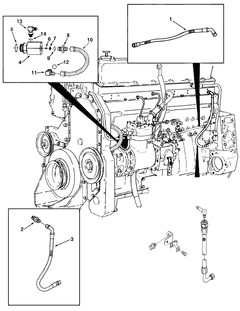

Installation and Integration

Installing the Cummins 3895960 Viscosity Sensor involves several steps and considerations to ensure proper integration with the truck’s engine system. It is designed to be compatible with various engine systems, making it a versatile choice for different commercial truck applications. The sensor can be integrated with other sensors and monitoring systems to provide comprehensive engine health data.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3895960 Viscosity Sensor include sensor malfunctions or inaccurate readings. Diagnostic procedures involve checking the sensor’s connections, ensuring it is properly installed, and verifying that it is receiving power. Regular maintenance practices, such as cleaning the sensor and inspecting it for damage, help ensure optimal performance and longevity.

Real-world Applications

The Cummins 3895960 Viscosity Sensor is used in various types of commercial trucks, including long-haul semi-trucks, construction vehicles, and delivery trucks. In these applications, the sensor plays a vital role in maintaining engine health and performance, contributing to the overall efficiency and reliability of the vehicle.

Technological Advancements

The Cummins 3895960 Viscosity Sensor incorporates several technological innovations, such as digital signal processing and wireless communication capabilities. These advancements enhance the sensor’s accuracy, reliability, and ease of use, making it a valuable tool for modern commercial truck fleets.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong commitment to innovation and quality, Cummins has established itself as a trusted name in the automotive industry, providing reliable and advanced products for various applications.

Compatibility with Cummins Engines

The Viscosity Sensor, identified by part number 3895960 and manufactured by Cummins, is designed to monitor the viscosity of engine oil in real-time. This sensor plays a role in ensuring the engine operates within optimal parameters by providing data to the engine control unit (ECU).

M11 CELECT PLUS Engine

The M11 CELECT PLUS engine benefits significantly from the Viscosity Sensor. This engine variant is equipped with advanced electronic controls that rely on precise data inputs to manage performance and efficiency. The sensor’s role in this context is to ensure that the oil maintains its required viscosity, which is important for the engine’s lubrication system to function correctly. This helps in preventing engine wear and maintaining overall engine health.

M11 MECHANICAL Engine

In the M11 MECHANICAL engine, the Viscosity Sensor, although not as electronically integrated as in the CELECT PLUS variant, still provides essential data. This engine relies on mechanical systems for its operation, and the sensor’s role here is to ensure that the oil viscosity remains within acceptable limits. This is particularly important in maintaining the engine’s longevity and performance, as the mechanical components are more susceptible to wear without proper lubrication.

Grouping Considerations

While both the M11 CELECT PLUS and M11 MECHANICAL engines utilize the Viscosity Sensor, the way they integrate and benefit from this component can be grouped based on their control systems. The CELECT PLUS engine, with its advanced electronic controls, represents a more integrated use of the sensor, leveraging real-time data for optimal performance. In contrast, the MECHANICAL engine uses the sensor in a more traditional role, ensuring that the engine’s mechanical systems are adequately lubricated without the benefit of electronic feedback systems.

Role of Part 3895960 Viscosity Sensor in Engine Systems

The integration of the Part 3895960 Viscosity Sensor within engine systems significantly enhances the precision and efficiency of various components. This sensor is instrumental in maintaining optimal engine performance by ensuring that the viscosity of the oil is consistently monitored and adjusted as necessary.

Interaction with Injectors

Injectors rely on precise oil viscosity to function effectively. The viscosity sensor provides real-time data that allows the engine control unit (ECU) to make necessary adjustments. This ensures that the injectors receive oil of the correct viscosity, which is essential for their performance and longevity. Proper viscosity helps in maintaining the injector’s spray pattern and atomization, leading to better fuel efficiency and reduced emissions.

Coordination with Oil Control Valves

Oil control valves (OCVs) are designed to regulate the flow of oil to different engine components. The viscosity sensor plays a key role here by providing accurate viscosity readings. This data enables the OCVs to adjust the oil flow dynamically, ensuring that each part of the engine receives the appropriate amount of oil. This results in reduced wear and tear on engine components, improved lubrication, and overall enhanced engine performance.

Impact on Engine Performance

Engine performance is directly influenced by the quality of lubrication. The viscosity sensor ensures that the oil’s viscosity is within the optimal range, which is vital for reducing friction between moving parts. Lower friction translates to less energy loss, higher efficiency, and smoother operation. Additionally, consistent viscosity helps in maintaining stable oil pressure, which is crucial for the reliable operation of various engine components.

Contribution to Overall System Efficiency

The viscosity sensor kit, including Part 3895960, is designed to work seamlessly with other engine components to enhance overall system efficiency. By providing accurate viscosity data, it allows the ECU to make informed decisions regarding oil management. This leads to better thermal management, reduced oil consumption, and extended intervals between oil changes. The sensor’s role in maintaining optimal oil conditions contributes to the engine’s durability and reliability over time.

Conclusion

The Cummins 3895960 Viscosity Sensor is a vital component in modern engine systems, ensuring that all interconnected parts—such as injectors and oil control valves—operate within their designed parameters for maximum performance and efficiency. Its role in monitoring and maintaining optimal oil viscosity is crucial for the longevity and reliability of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.