Understanding The Cummins Sensor Bracket Part #3931556

Introduction To Sensor Brackets

Sensor brackets are essential components in the architecture of commercial trucks and heavy-duty vehicles. They serve as mounting points for various sensors that are crucial for engine management and diagnostics. These brackets ensure that sensors are securely positioned and aligned correctly to perform their functions effectively 1.

The Role Of A Sensor Bracket In Truck Engines

A sensor bracket, such as the Cummins part #3931556, plays a pivotal role in the operation of a truck’s engine. It holds sensors in place, which monitor parameters such as temperature, pressure, and flow rates. These sensors relay vital information to the engine control unit (ECU), enabling it to make real-time adjustments for optimal performance and efficiency 2.

Functionality Of The Cummins Part #3931556 Sensor Bracket

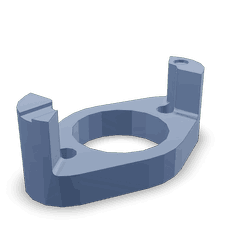

The Cummins part #3931556 sensor bracket is specifically designed to support and secure sensors within the engine compartment. It ensures that the sensors are positioned correctly to capture accurate data. This data is essential for the ECU to manage fuel injection, ignition timing, and other critical engine functions. The design of this bracket allows for easy installation and removal, facilitating maintenance and sensor replacement when necessary 3.

Importance Of Proper Sensor Bracket Installation

Proper installation of the sensor bracket is crucial for the accurate functioning of the sensors. Misalignment or loose mounting can lead to erroneous readings, which can adversely affect engine performance and fuel efficiency. It is essential to follow the manufacturer’s guidelines for installation to ensure that the sensor bracket performs its role effectively. This includes using the correct fasteners and torque specifications to secure the bracket in place 1.

Troubleshooting And Maintenance Of Sensor Brackets

Regular maintenance of the sensor bracket is necessary to ensure its longevity and effectiveness. Engineers and mechanics should inspect the bracket for any signs of wear, corrosion, or damage. If any issues are detected, the bracket should be replaced promptly to prevent sensor misalignment and potential engine problems. Additionally, ensuring that the sensors themselves are clean and free from debris is crucial for accurate readings 2.

Cummins: A Leader In Engine Technology

Cummins is a renowned manufacturer of engines and related components for commercial trucks and heavy-duty vehicles. Their commitment to quality and innovation has made them a trusted name in the industry. The Cummins part #3931556 sensor bracket is a testament to their dedication to providing reliable and durable components for the trucking industry. Cummins components are designed to meet the rigorous demands of heavy-duty applications, ensuring long-term performance and reliability 3.

Best Practices For Sensor Bracket Maintenance

To maintain the sensor bracket in optimal condition, engineers and mechanics should adhere to the following best practices:

- Regular Inspections: Conduct routine inspections to check for signs of wear, corrosion, or damage.

- Cleaning: Keep the sensor bracket clean to prevent dirt and debris from affecting sensor performance.

- Secure Fastening: Ensure that all bolts and fasteners are tightened to the manufacturer’s specifications to maintain proper sensor alignment.

- Replacement: Replace the sensor bracket if any damage is detected to prevent potential engine issues.

Conclusion

The Cummins part #3931556 sensor bracket is a critical component in the engine management system of commercial trucks and heavy-duty vehicles. Its role in securing and aligning sensors is essential for accurate engine diagnostics and performance. Proper maintenance and installation of this sensor bracket are vital to ensure the longevity and effectiveness of the sensors it supports. Cummins’ reputation for quality and innovation makes their sensor brackets a reliable choice for the trucking industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.