This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3934497 Fuel Injector Pump is a vital component in heavy-duty truck engines, ensuring the engine receives the precise amount of fuel needed for optimal performance and efficiency. This part is integral to the operation of diesel engines, where precise fuel delivery is crucial for both power output and fuel economy 1.

Basic Concepts of Fuel Injector Pumps

A fuel injector pump pressurizes fuel and delivers it to the injectors in a diesel engine. It operates based on the principle of fuel injection, where pressurized fuel is injected into the combustion chamber at precise moments to ensure efficient combustion. The pump’s role is to provide the necessary pressure and timing for fuel delivery, which is essential for the engine’s performance and emissions control 2.

Purpose of the Cummins 3934497 Fuel Injector Pump

This Cummins part is designed to enhance the operation of heavy-duty trucks. It ensures that fuel is delivered at the correct pressure and timing, contributing to better fuel efficiency and overall engine functionality. The pump maintains the engine’s power output while optimizing fuel consumption 3.

Key Features

The Cummins 3934497 Fuel Injector Pump features high-quality materials that ensure longevity and reliability. It is engineered to withstand the demanding conditions of heavy-duty truck engines, providing consistent fuel delivery under various operating conditions. Advanced sealing technology and precise manufacturing tolerances contribute to its robust performance.

Benefits

Using the Cummins 3934497 Fuel Injector Pump improves fuel efficiency by ensuring optimal pressure and timing for fuel delivery, resulting in better combustion and reduced fuel consumption. It enhances engine performance, providing consistent power output and reliability. Its durable construction ensures longevity, reducing the need for frequent replacements and maintenance.

Installation and Integration

Installing the Cummins 3934497 Fuel Injector Pump requires careful consideration of compatibility with various engine models. Proper installation involves following manufacturer guidelines to ensure the pump is correctly integrated into the fuel system. Specific requirements may include aligning the pump with the engine’s fuel lines and ensuring all connections are secure and leak-free.

Maintenance and Troubleshooting

Maintaining the Cummins 3934497 Fuel Injector Pump is crucial for optimal performance. Regular maintenance includes checking for leaks, ensuring proper fuel line connections, and monitoring the pump’s performance. Common issues may involve fuel delivery inconsistencies or pump wear, which can be addressed through routine inspections and timely replacements of worn components. Recommended maintenance schedules should be followed to prevent potential problems.

Performance and Efficiency

The Cummins 3934497 Fuel Injector Pump significantly contributes to the overall performance and efficiency of heavy-duty trucks. By providing precise fuel delivery, it ensures consistent engine performance and improved fuel economy. Real-world examples and data demonstrate that trucks equipped with this pump achieve better fuel efficiency and reliable operation, making it a valuable component in the fuel system.

Safety Considerations

When working with the Cummins 3934497 Fuel Injector Pump, it is important to observe safety considerations. Proper handling, installation, and maintenance practices are essential to ensure the safety of mechanics and operators. This includes following manufacturer guidelines, using appropriate personal protective equipment, and ensuring all components are correctly installed and secured.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the automotive industry. The company is committed to producing high-quality components that meet the demanding requirements of heavy-duty applications. Cummins’ history of innovation and dedication to quality ensures that their products, including the 3934497 Fuel Injector Pump, are reliable and perform well under various conditions.

Cummins Fuel Injector Pump 3934497 Compatibility

The Cummins Fuel Injector Pump part number 3934497 is designed to fit a variety of Cummins engines, ensuring precise fuel delivery and optimal engine performance. Here is a detailed overview of the engines with which this part is compatible:

Cummins 4B3.9

The 4B3.9 engine is part of the Cummins B Series, known for its reliability and efficiency. The 3934497 fuel injector pump is engineered to work seamlessly with this engine, providing the necessary fuel metering and pressure for smooth operation.

Cummins 6B5.9

Similar to the 4B3.9, the 6B5.9 engine is also part of the Cummins B Series. This engine benefits from the 3934497 fuel injector pump, which ensures that the fuel is delivered at the correct pressure and timing, enhancing the engine’s performance and longevity.

Cummins 6C8.3

The 6C8.3 engine is another member of the Cummins C Series, recognized for its power and durability. The 3934497 fuel injector pump is specifically designed to match the requirements of this engine, ensuring efficient fuel injection and optimal combustion.

Cummins QSB5.9

The QSB5.9 engine is part of the Cummins QSB Series, which is widely used in various applications due to its robust design and performance. The 3934497 fuel injector pump is compatible with this engine, providing the precise fuel delivery needed for efficient operation.

Cummins 44 CM550

The 44 CM550 engine is part of the Cummins C Series, known for its versatility and power. The 3934497 fuel injector pump is engineered to fit this engine, ensuring that the fuel is injected at the correct pressure and timing, which is crucial for maintaining engine efficiency and performance.

By ensuring compatibility with these engines, the Cummins Fuel Injector Pump 3934497 plays a critical role in maintaining the performance and reliability of the engines it is designed to work with.

Role of Part 3934497 Fuel Injector Pump in Engine Systems

The 3934497 Fuel Injector Pump is integral to the efficient operation of various engine systems. It works in concert with multiple components to ensure optimal engine performance and reliability.

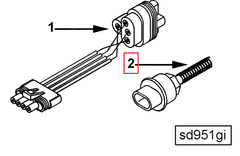

Integration with Sensors

The Fuel Injector Pump interfaces with both the Coolant Level Sensor and the Oil Level Sensor. The Coolant Level Sensor monitors the coolant levels within the engine, ensuring that the engine operates within safe temperature ranges. The Fuel Injector Pump adjusts fuel delivery based on the temperature data received, optimizing combustion efficiency and protecting the engine from overheating.

Similarly, the Oil Level Sensor provides real-time data on the oil levels within the engine. The Fuel Injector Pump uses this information to maintain the appropriate lubrication for engine components, ensuring smooth operation and reducing wear and tear.

Coordination with Engine Monitoring System

The Engine Monitoring System (EMS) plays a significant role in maintaining engine health by continuously collecting data from various sensors, including the Coolant Level Sensor and the Oil Level Sensor. The 3934497 Fuel Injector Pump communicates with the EMS to fine-tune fuel injection parameters. This ensures that the engine operates efficiently under varying conditions, whether idling, accelerating, or decelerating.

Enhancing Overall Engine Performance

By precisely controlling the fuel injection process, the 3934497 Fuel Injector Pump contributes to the overall performance and longevity of the engine. It ensures that the right amount of fuel is delivered at the right time, which is essential for maintaining engine power, fuel efficiency, and emissions standards.

Conclusion

In summary, the 3934497 Fuel Injector Pump is a key component that works in harmony with sensors and the Engine Monitoring System to deliver optimal engine performance and reliability. Its precise fuel delivery ensures that the engine operates efficiently, contributing to better fuel economy and overall engine functionality.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.