Introduction

The Cummins 4002066 Position Sensor is a critical component designed to monitor and report the position of various parts within the engine of commercial trucks. This sensor ensures the engine operates efficiently and reliably by providing precise data to the engine control unit (ECU) 3.

Basic Concepts of Position Sensors

Position sensors are devices that detect the position of an object and convert it into an electrical signal. They are widely used in automotive systems to monitor the position of components such as valves, pistons, and other moving parts. These sensors help maintain the optimal operation of the engine by providing real-time data to the ECU, which then makes necessary adjustments to ensure efficient performance 1.

Purpose of the Cummins 4002066 Position Sensor

This Cummins part is specifically designed to monitor the position of certain engine components within commercial trucks. It plays a role in the engine management system by providing accurate positional data to the ECU. This data allows the ECU to make precise adjustments to fuel injection timing, valve timing, and other critical parameters, thereby enhancing engine performance and efficiency 3.

Key Features

The Cummins 4002066 Position Sensor is characterized by its robust design and high-quality materials, which ensure durability and reliability in demanding environments. It incorporates advanced technological specifications that enhance its performance, such as high-resolution sensing capabilities and resistance to environmental factors like temperature variations and vibrations 2.

Benefits

The advantages provided by this part include improved engine performance through precise control of engine parameters, enhanced fuel efficiency by optimizing fuel injection timing, and increased reliability of the truck’s systems due to accurate monitoring and feedback. These benefits contribute to the overall efficiency and longevity of the vehicle 3.

Installation and Integration

Installing the Cummins 4002066 Position Sensor involves mounting it in the appropriate location within the engine compartment and connecting it to the engine management system. Careful consideration must be given to ensure proper alignment and secure attachment to avoid any issues with data accuracy. Integration with the ECU requires following manufacturer guidelines to ensure compatibility and optimal performance 3.

Common Applications

The Cummins 4002066 Position Sensor is typically used in various types of commercial trucks and engine configurations. It is compatible with a range of Cummins engines and is often found in applications where precise engine management is crucial for performance and efficiency 3.

Troubleshooting and Maintenance

Identifying common issues with the Cummins 4002066 Position Sensor may involve checking for signs of physical damage, ensuring secure connections, and verifying the accuracy of the data it provides. Troubleshooting steps can include recalibrating the sensor or replacing it if necessary. Regular maintenance practices, such as inspecting the sensor for wear and ensuring it is free from contaminants, can help ensure optimal performance and longevity 3.

Performance Impact

The Cummins 4002066 Position Sensor affects the overall performance of the truck by contributing to better fuel economy through optimized fuel injection, reduced emissions by ensuring precise control over engine parameters, and enhanced engine responsiveness due to accurate monitoring and feedback 3.

Technological Advancements

The Cummins 4002066 Position Sensor incorporates several technological innovations that set it apart from earlier models or competing products. These include improved sensing accuracy, enhanced durability through the use of high-quality materials, and advanced integration capabilities with modern engine management systems 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a rich history in the commercial truck industry, Cummins is known for its comprehensive product range and strong reputation for quality and reliability. The company continues to innovate and provide solutions that meet the evolving needs of the transportation sector 3.

Compatibility

The Cummins Position Sensor part number 4002066 is designed to integrate seamlessly with a range of Cummins engines, ensuring precise engine performance and reliability. This sensor is crucial for monitoring the position of various engine components, which helps maintain optimal engine operation.

ISB CM550

The ISB CM550 engine benefits from the 4002066 Position Sensor, providing accurate data for the engine control unit (ECU). This ensures that the engine operates efficiently and reliably, particularly in demanding applications.

QSB5.9 44 CM550

Similarly, the QSB5.9 44 CM550 engine is equipped with the 4002066 Position Sensor, which plays a pivotal role in the engine’s performance. The sensor’s precision allows for better control over engine functions, enhancing overall efficiency and durability.

Grouped Engines

Both the ISB CM550 and QSB5.9 44 CM550 engines share a common reliance on the 4002066 Position Sensor for their operational integrity. The sensor’s compatibility with these engines underscores its versatility and importance in maintaining engine performance across different applications.

Role of 4002066 Position Sensor in Engine Systems

This part is integral to the operation of several engine components, ensuring precise and efficient performance.

Interaction with the Engine Control Module (ECM)

The Position Sensor provides real-time data to the Engine Control Module (ECM). This data includes the position and speed of various engine components, allowing the ECM to make necessary adjustments to fuel injection, ignition timing, and other critical parameters. The sensor’s accurate readings enable the ECM to optimize engine performance, enhance fuel efficiency, and reduce emissions 3.

Enhancing Engine Performance

By continuously monitoring the position of engine components, the Position Sensor ensures that the ECM can respond promptly to changes in operating conditions. This results in smoother operation, improved throttle response, and better overall engine performance. The sensor’s role is particularly important in modern engines, where precise control is essential for meeting stringent emissions standards and achieving high efficiency 3.

Supporting Diagnostic Functions

The data provided by the Position Sensor is also vital for onboard diagnostics. The ECM uses this information to detect anomalies and potential issues within the engine system. Early detection of problems allows for timely maintenance, preventing more severe damage and extending the lifespan of the engine components 3.

Integration with Other Systems

Beyond its primary role with the ECM, the Position Sensor interacts with other engine systems, such as the variable valve timing (VVT) system and the electronic throttle control (ETC) system. By providing accurate position data, the sensor ensures these systems operate in harmony, further enhancing engine performance and drivability 3.

Conclusion

The Cummins 4002066 Position Sensor is a key component in modern engine systems, facilitating precise control and optimal performance through its interaction with the ECM and other critical systems. Its robust design, advanced features, and compatibility with various Cummins engines make it an essential part of ensuring efficient and reliable engine operation 3.

-

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

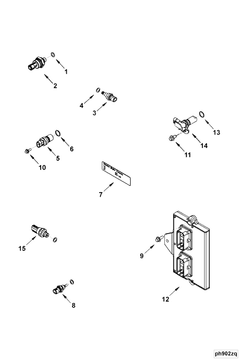

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.