This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

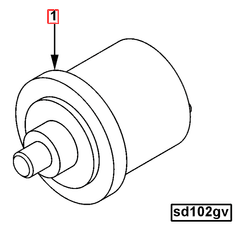

The Cummins 4071833 Pressure Sensor is a component designed to monitor and measure pressure levels within the systems of commercial trucks. Its purpose is to provide accurate pressure readings that are vital for the proper operation and maintenance of the vehicle. This sensor plays a role in ensuring the truck operates efficiently and safely by supplying data to the truck’s control systems 1.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that detect the pressure of gases or liquids. They convert the pressure into an electrical signal, which can then be measured and analyzed. In automotive systems, pressure sensors are used to monitor various parameters such as fuel pressure, oil pressure, and air intake pressure. These sensors help in maintaining optimal performance and preventing potential issues by providing real-time data to the vehicle’s electronic control unit (ECU) 2.

Role of the 4071833 Pressure Sensor in Truck Operation

The Cummins 4071833 Pressure Sensor is integrated into the truck’s systems to monitor specific pressure points. It provides data that is used by the ECU to make adjustments to the engine and other systems, ensuring they operate within the desired parameters. This sensor helps in maintaining engine performance, fuel efficiency, and overall system integrity by delivering precise pressure readings 3.

Key Features of the 4071833 Pressure Sensor

The Cummins 4071833 Pressure Sensor is characterized by its robust design and high-quality materials, which ensure durability and reliability. It incorporates advanced technological specifications that enhance its performance, such as high accuracy in pressure measurement and resistance to environmental factors like temperature variations and vibrations 4.

Benefits of Using the 4071833 Pressure Sensor

Utilizing the Cummins 4071833 Pressure Sensor offers several advantages. It contributes to improved engine performance by ensuring that the engine operates under optimal pressure conditions. This sensor also enhances safety by providing accurate data that helps prevent system failures. Additionally, it increases efficiency in truck operations by enabling the ECU to make precise adjustments, leading to better fuel economy and reduced wear on components 5.

Installation and Integration

Proper installation of the Cummins 4071833 Pressure Sensor is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is correctly positioned and connected within the truck’s system. This may involve securing the sensor in place, connecting it to the appropriate pressure points, and ensuring all electrical connections are secure and properly insulated 6.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4071833 Pressure Sensor is important to ensure its longevity and optimal performance. This includes checking for any signs of wear or damage, ensuring all connections are secure, and verifying that the sensor is providing accurate readings. Common troubleshooting tips include calibrating the sensor if readings are inconsistent and replacing it if it shows signs of failure 7.

Compatibility and Applications

The Cummins 4071833 Pressure Sensor is designed to be compatible with a range of commercial trucks and systems. It is commonly used in applications where precise pressure monitoring is required to ensure the efficient and safe operation of the vehicle 8.

Technological Advancements

The Cummins 4071833 Pressure Sensor incorporates several technological innovations that distinguish it from other pressure sensors in the market. These include advanced materials that offer greater durability, sophisticated sensing technology for higher accuracy, and design features that enhance its resistance to environmental factors 9.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s focus on technological advancement and customer satisfaction underscores its position as a leader in providing reliable and efficient power solutions 10.

Integration with Specific Engines

4B3.9 and 6B5.9 Engines

The 4071833 Pressure Sensor is compatible with the 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The pressure sensor in these engines plays a role in ensuring that the engine operates within the optimal pressure range, thereby enhancing performance and longevity.

6C8.3 and B3.3 Engines

Similarly, the 6C8.3 and B3.3 engines benefit from the integration of the 4071833 Pressure Sensor. These engines are designed for versatility and efficiency, making them suitable for a variety of applications. The pressure sensor ensures that these engines maintain the necessary pressure levels, contributing to their overall efficiency and reliability.

Compatibility with K19 Engines

The K19 engine also supports the use of the 4071833 Pressure Sensor. This engine is known for its high power output and durability, often used in demanding industrial and commercial applications. The pressure sensor is integral to the K19 engine’s operation, providing data that helps in maintaining optimal performance and preventing potential issues.

Role of Part 4071833 Pressure Sensor in Engine Systems

Integration with Engine Mounting Parts Kit

When installed, the 4071833 Pressure Sensor interacts with the engine mounting parts kit to provide real-time data on the engine’s operational status. The sensor is typically mounted in a location that allows it to accurately measure pressure changes within the engine. The mounting parts kit ensures that the sensor is securely fastened, minimizing vibrations and ensuring consistent readings. This setup allows for precise monitoring of engine conditions, facilitating timely maintenance and adjustments.

Interaction with Other Sensors

The 4071833 Pressure Sensor often works in tandem with other sensors within the engine system. These sensors collectively provide a comprehensive dataset that the engine control unit (ECU) uses to make adjustments in real-time. For instance, the pressure sensor may communicate with temperature sensors and airflow meters to optimize fuel injection and ignition timing. This collaborative effort enhances engine efficiency and reduces emissions.

Oil Pressure Monitoring

One of the primary functions of the 4071833 Pressure Sensor is to monitor oil pressure within the engine. Accurate oil pressure readings are essential for maintaining proper lubrication of moving parts, preventing wear and tear, and ensuring the engine operates within safe parameters. The sensor sends data to the ECU, which can then trigger warnings or take corrective actions if oil pressure drops below acceptable levels. This proactive monitoring helps in preventing catastrophic engine failures.

Enhanced Diagnostic Capabilities

The data collected by the 4071833 Pressure Sensor contributes to the overall diagnostic capabilities of the engine system. Mechanics and engineers can use this data to identify trends, predict potential issues, and perform preventive maintenance. For example, a gradual decrease in oil pressure might indicate a need for an oil change or filter replacement, whereas sudden drops could signal more serious problems like a failing oil pump or blocked passages.

Conclusion

The Cummins 4071833 Pressure Sensor is a vital component in the operation and maintenance of commercial trucks and engines. Its accurate pressure readings ensure optimal engine performance, fuel efficiency, and safety. The sensor’s robust design, advanced technological features, and compatibility with various engine models make it an essential part of modern engine systems. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this sensor.

-

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.