This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4326867 Nitrogen Oxide Sensor is a component designed to monitor nitrogen oxide (NOx) levels in the exhaust of heavy-duty trucks. It plays a role in the emissions control system by providing accurate NOx measurements, which are vital for maintaining emissions within regulatory limits and ensuring efficient engine performance 1.

Basic Concepts of Nitrogen Oxide Sensors

Nitrogen oxides (NOx) are a group of gases formed during the combustion process in diesel engines. They are a significant concern due to their environmental impact and contribution to air pollution. Monitoring NOx levels is important for reducing emissions and meeting environmental regulations. Nitrogen oxide sensors, like the Cummins 4326867, utilize advanced technology to measure NOx concentrations in the exhaust. These sensors typically employ electrochemical cells or infrared spectroscopy to detect NOx levels accurately 2.

Purpose of the Cummins 4326867 Nitrogen Oxide Sensor

The Cummins 4326867 Nitrogen Oxide Sensor is integral to the operation of heavy-duty trucks. It provides real-time data on NOx levels, allowing the engine control unit (ECU) to adjust fuel injection and exhaust treatment systems accordingly. This ensures that emissions remain within regulatory limits while optimizing engine performance. The sensor contributes to a cleaner environment by facilitating precise control over NOx emissions 3.

Key Features

The Cummins 4326867 Nitrogen Oxide Sensor is characterized by its robust design and high-quality construction materials. It incorporates advanced sensor technology that enhances its accuracy and durability. The sensor is engineered to withstand the harsh conditions of heavy-duty truck exhaust systems, ensuring reliable performance over time. Its design allows for easy integration into existing emissions control systems 4.

Benefits

Using the Cummins 4326867 Nitrogen Oxide Sensor offers several benefits. It improves emissions control by providing accurate NOx measurements, which enable the ECU to make precise adjustments to the engine and exhaust treatment systems. This leads to enhanced engine efficiency and reduced environmental impact. Additionally, the sensor helps fleet operators comply with stringent environmental regulations, potentially resulting in cost savings by avoiding fines and maintaining vehicle uptime 5.

Installation and Integration

Proper installation of the Cummins 4326867 Nitrogen Oxide Sensor is crucial for optimal performance. It should be installed in accordance with the manufacturer’s guidelines to ensure accurate readings and reliable operation. Integration into the truck’s emissions control system may require adjustments or calibrations to the ECU to ensure compatibility and effectiveness. Following the recommended procedures will help achieve the best results 6.

Troubleshooting and Maintenance

Regular maintenance of the Cummins 4326867 Nitrogen Oxide Sensor is important to ensure its continued effectiveness. Common issues may include sensor fouling or electrical connections problems. Troubleshooting should begin with a visual inspection of the sensor and its connections. Cleaning the sensor according to the manufacturer’s recommendations can help maintain its accuracy. Periodic checks and calibrations may also be necessary to ensure optimal performance 7.

Regulatory Compliance

The Cummins 4326867 Nitrogen Oxide Sensor plays a role in helping heavy-duty trucks meet emissions regulations. Accurate NOx measurement is fundamental to achieving and maintaining compliance with environmental standards. By providing precise data on NOx levels, the sensor enables the ECU to make the necessary adjustments to keep emissions within legal limits, supporting environmental responsibility and regulatory adherence 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company is committed to innovation, quality, and environmental responsibility, continually developing advanced technologies to improve engine efficiency and reduce emissions 9.

Nitrogen Oxide Sensor Compatibility with Cummins Engines

The Nitrogen Oxide Sensor, part number 4326867, manufactured by Cummins, is a critical component for monitoring and regulating nitrogen oxide emissions in various Cummins engine models. This sensor is designed to fit seamlessly with a range of Cummins engines, ensuring compliance with environmental regulations and optimal engine performance.

B-Series Engines

The B4.5 CM2350 B104 and B6.7 CM2350 B135B engines are part of the B-Series family. The Nitrogen Oxide Sensor is engineered to integrate smoothly with these engines, providing accurate readings and contributing to the overall efficiency of the exhaust after-treatment system.

F-Series Engines

For the F3.8 CM2350 F120B and F3.8 CM2350 F128C engines, the Nitrogen Oxide Sensor is a perfect match. These engines benefit from the sensor’s precise monitoring capabilities, ensuring that nitrogen oxide emissions are kept within permissible limits.

ISB-Series Engines

The ISB4.5 CM2350 B104 and ISB6.7 CM2350 B101 engines are part of the ISB-Series. The Nitrogen Oxide Sensor is designed to fit these engines, providing reliable data that helps in the effective management of exhaust emissions.

QSK-Series Engines

The QSK19 CM2350 K105, QSK19 CM2350 K114, QSK50 CM2350 K108, and QSK95 CM2350 K113 engines are part of the QSK-Series. The Nitrogen Oxide Sensor is compatible with these engines, ensuring that they meet stringent emission standards while maintaining peak performance.

QST-Series Engines

The QST30 CM2350 T101 engine is part of the QST-Series. The Nitrogen Oxide Sensor is designed to fit this engine, providing essential data for the management of nitrogen oxide emissions.

QSX-Series Engines

The QSX15 CM2350 X105 engine is part of the QSX-Series. The Nitrogen Oxide Sensor is compatible with this engine, ensuring that it operates efficiently while adhering to environmental regulations.

QSF-Series Engines

The QSF3.8 CM2350 F107 engine is part of the QSF-Series. The Nitrogen Oxide Sensor is designed to fit this engine, providing accurate monitoring of nitrogen oxide emissions.

Each of these engines relies on the Nitrogen Oxide Sensor to maintain optimal performance and compliance with environmental standards. The sensor’s compatibility with these various engine models underscores Cummins’ commitment to providing reliable and efficient solutions for emission control.

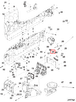

Role of Part 4326867 Nitrogen Oxide Sensor in Engine Systems

The integration of the Nitrogen Oxide Sensor (Part 4326867) within engine systems is essential for maintaining efficient and compliant emissions control. This sensor is strategically positioned within the aftertreatment system, typically upstream or downstream of the decomposition reactor, to monitor the levels of nitrogen oxides (NOx) in the exhaust gases.

Interaction with Aftertreatment Devices

The Nitrogen Oxide Sensor works in concert with the aftertreatment device to ensure that NOx levels are within regulatory limits. By providing real-time data on NOx concentrations, the sensor allows the engine control module (ECM) to make necessary adjustments to the fuel injection timing and air-fuel ratio. This dynamic feedback loop is vital for the optimal performance of the aftertreatment system, which relies on precise control to convert harmful NOx into less harmful nitrogen and oxygen 10.

Communication with the Engine Control Module

The sensor’s location is critical for its function. Mounted on a dedicated sensor bracket, the Nitrogen Oxide Sensor is positioned to offer accurate readings of exhaust gas composition. These readings are transmitted to the ECM, which uses the data to fine-tune engine operations. The ECM can then adjust various parameters, such as the injection of urea into the exhaust stream (in Selective Catalytic Reduction systems) or the timing of the exhaust gas recirculation (EGR) valve, to maintain low NOx emissions 11.

Ensuring System Efficiency

The Nitrogen Oxide Sensor’s role extends beyond mere monitoring; it is integral to the overall efficiency of the aftertreatment system. By providing continuous feedback, the sensor ensures that the decomposition reactor operates under optimal conditions. This not only helps in meeting emissions standards but also contributes to the longevity and reliability of the aftertreatment components 12.

Conclusion

In summary, the Nitrogen Oxide Sensor (Part 4326867) is a key component in the orchestration of engine and aftertreatment system functions, ensuring that emissions are controlled effectively while maintaining engine performance. Its role in providing accurate NOx measurements, facilitating compliance with environmental regulations, and enhancing engine efficiency underscores its importance in modern heavy-duty truck engines.

-

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021489, Operation and Maintenance Manual.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021489, Operation and Maintenance Manual.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021489, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021489, Operation and Maintenance Manual.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.