This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4358994 Differential Pressure Sensor is a component designed to monitor and measure the pressure difference between two points in a system. In the context of commercial trucks, this sensor plays a role in the efficient and safe operation of the vehicle by providing data that helps ensure the truck’s systems operate within optimal parameters, contributing to overall performance and longevity 1.

Basic Concepts of Differential Pressure Sensors

A differential pressure sensor measures the difference in pressure between two points. It operates by using a diaphragm that flexes in response to pressure differences, converting mechanical motion into an electrical signal. This signal is then processed to provide a reading that can be used for various applications. In automotive systems, these sensors are commonly used to monitor filtration systems, turbochargers, and exhaust gas recirculation (EGR) systems, among others 2.

Role of the Cummins 4358994 Differential Pressure Sensor in Truck Operation

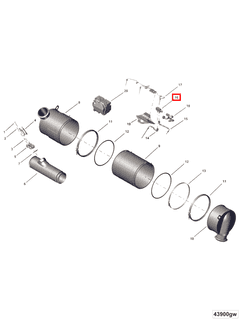

The Cummins 4358994 Differential Pressure Sensor is integrated into the truck’s systems to monitor specific parameters that are important for operation. It is typically used in diesel particulate filter (DPF) systems to measure the pressure difference across the filter. This measurement helps in determining the filter’s condition and efficiency. By monitoring this parameter, the sensor aids in the truck’s emission control system, ensuring that the vehicle meets environmental regulations while maintaining performance 3.

Key Features of the Cummins 4358994 Differential Pressure Sensor

The Cummins 4358994 Differential Pressure Sensor is characterized by several key features that enhance its performance and reliability. Its design incorporates a robust diaphragm that is resistant to the harsh conditions found in a truck’s engine compartment. The sensor is constructed using high-quality materials that ensure durability and accuracy over time. Technological advancements in the sensor’s design allow for precise measurements, contributing to its effectiveness in monitoring system parameters 4.

Benefits of Using the Cummins 4358994 Differential Pressure Sensor

Utilizing the Cummins 4358994 Differential Pressure Sensor offers several advantages. It contributes to improved efficiency by ensuring that the truck’s systems operate within optimal parameters. This can lead to enhanced fuel economy and reduced emissions. Additionally, the sensor plays a role in enhancing safety by providing data that helps in the early detection of potential issues, allowing for timely maintenance. Fleet operators may also experience cost savings due to the sensor’s contribution to efficient operation and reduced downtime 2.

Installation and Integration

Proper installation and integration of the Cummins 4358994 Differential Pressure Sensor into a truck’s system are crucial for its effective operation. Installation should be performed according to the manufacturer’s guidelines, ensuring that the sensor is correctly positioned and connected. It is important to verify that the sensor is compatible with the truck’s system and that all connections are secure. Consideration should also be given to the sensor’s exposure to environmental conditions, ensuring it is protected from excessive heat, moisture, and vibration 3.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Cummins 4358994 Differential Pressure Sensor, regular maintenance and troubleshooting are recommended. Common issues may include inaccurate readings or sensor failure, which can often be traced back to wiring problems, contamination, or physical damage. Regular inspection and cleaning of the sensor and its connections can help prevent these issues. Signs of potential failure may include unusual readings, warning lights on the dashboard, or decreased performance, indicating the need for further investigation or replacement 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a reputable name in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its standing in the industry, making it a preferred choice for fleet operators and manufacturers alike.

Differential Pressure Sensor 4358994 Compatibility with Cummins Engines

The Differential Pressure Sensor 4358994, manufactured by Cummins, is designed to monitor and regulate the pressure differentials within the engine systems of various Cummins engine models. This sensor ensures optimal engine performance by providing accurate pressure readings, which are essential for maintaining the engine’s efficiency and longevity.

Compatibility with Specific Engine Models

X12 CM2350 X119B and X15 CM2350 X116B

The Differential Pressure Sensor 4358994 is compatible with the X12 CM2350 X119B and X15 CM2350 X116B engines. These engines are part of the Cummins CM2350 series, known for their robust design and reliable performance in various applications. The sensor’s integration into these engines is seamless, ensuring that it can effectively communicate with the engine control unit (ECU) to provide real-time data on pressure differentials. This data is crucial for the ECU to make necessary adjustments to maintain optimal engine operation.

X15 CM2450 X134B

Similarly, the X15 CM2450 X134B engine is also compatible with the Differential Pressure Sensor 4358994. This engine belongs to the Cummins CM2450 series, which is designed for high-performance applications. The sensor’s compatibility with this engine ensures that it can handle the higher pressure differentials typically encountered in these demanding environments. The sensor’s precision and reliability are vital for the X15 CM2450 X134B engine to operate efficiently and safely.

Integration and Functionality

The Differential Pressure Sensor 4358994 is engineered to integrate smoothly with the engine’s existing systems. Its placement within the engine is strategic, allowing it to capture accurate pressure differentials that are essential for the engine’s operation. The sensor communicates with the ECU, providing real-time data that helps in making necessary adjustments to maintain optimal engine performance. This integration ensures that the engine can respond quickly to changes in pressure, thereby enhancing its overall efficiency and reliability.

Role of Part 4358994 Differential Pressure Sensor in Engine Systems

In modern engine systems, the integration of the Differential Pressure Sensor (Part 4358994) is important for maintaining optimal performance and efficiency. This sensor plays a role in monitoring and regulating various components within the engine and aftertreatment systems.

Integration with the Device

The Differential Pressure Sensor is typically installed in the device to measure the pressure differential across specific components. This measurement is vital for ensuring that the device operates within its designed parameters. By continuously monitoring pressure changes, the sensor provides real-time data to the engine control unit (ECU), allowing for precise adjustments to be made. This ensures that the device functions efficiently, reducing the risk of malfunctions and extending its operational lifespan.

Contribution to Aftertreatment Systems

In aftertreatment systems, the Differential Pressure Sensor is instrumental in maintaining the effectiveness of components such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems. The sensor measures the pressure differential across these filters, indicating the level of particulate matter accumulation.

For DPFs, the sensor helps in determining when a regeneration cycle is necessary. During regeneration, accumulated soot is burned off, restoring the filter’s efficiency. The Differential Pressure Sensor ensures that this process is initiated at the optimal time, preventing excessive soot buildup that could lead to filter damage.

In SCR systems, the sensor monitors the pressure differential across the catalyst, ensuring that the system remains unclogged and operates efficiently. This is particularly important for maintaining the correct flow of exhaust gases and the effective reduction of nitrogen oxides (NOx).

Overall, the Differential Pressure Sensor (Part 4358994) is a key component in enhancing the performance and reliability of both the device and aftertreatment systems within modern engine configurations.

Conclusion

The Cummins 4358994 Differential Pressure Sensor is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its role in monitoring and regulating pressure differentials ensures optimal performance, efficiency, and safety. By integrating this sensor into engine and aftertreatment systems, fleet operators can achieve enhanced fuel economy, reduced emissions, and improved reliability. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part, contributing to the longevity and effectiveness of the vehicle’s systems.

-

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ ↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ ↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.