This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4383979 Particulate Sensor is a component designed to monitor and manage particulate matter in the exhaust systems of heavy-duty trucks. Its role is significant in ensuring that these vehicles operate within the parameters set by emissions regulations, thereby contributing to environmental protection and engine efficiency 1.

Basic Concepts of Particulate Sensors

Particulate sensors are devices that measure the concentration of particulate matter in diesel exhaust. They function by detecting the amount of light scattered by particles as they pass through a sensing chamber. This data is then used by the engine management system to adjust fuel injection and other parameters to minimize emissions. Particulate sensors play a role in maintaining the balance between engine performance and environmental compliance 2.

Purpose of the Cummins 4383979 Particulate Sensor

The Cummins 4383979 Particulate Sensor is designed to monitor the levels of particulate matter in diesel exhaust. By providing real-time data on particulate concentrations, it enables the engine management system to make adjustments that ensure compliance with emissions regulations. This sensor contributes to reducing the environmental impact of heavy-duty trucks by facilitating more efficient and cleaner engine operation 3.

Key Features

The Cummins 4383979 Particulate Sensor features a robust design that incorporates advanced materials to withstand the harsh conditions of diesel exhaust environments. Its construction includes precision-engineered components that ensure accurate and reliable measurements. Technological advancements in this sensor enhance its ability to provide consistent performance over time, supporting both engine efficiency and emissions control 4.

Benefits of Using the Cummins 4383979 Particulate Sensor

Utilizing the Cummins 4383979 Particulate Sensor offers several advantages. It contributes to improved emissions control by providing accurate data for engine management adjustments. This sensor also plays a role in enhancing engine performance by ensuring optimal combustion conditions. Additionally, it supports increased fuel efficiency through precise monitoring and adjustment of exhaust particulate levels 5.

Installation and Integration

Proper installation and integration of the Cummins 4383979 Particulate Sensor into heavy-duty truck engine systems require adherence to manufacturer guidelines. This includes ensuring correct placement within the exhaust system and secure connection to the engine management system. Careful attention to these details during installation helps maintain the sensor’s accuracy and reliability 6.

Troubleshooting and Maintenance

To maintain optimal performance, the Cummins 4383979 Particulate Sensor should be regularly inspected for signs of wear or damage. Common issues may include sensor fouling or electrical connection problems, which can be addressed through cleaning or repair as necessary. Routine maintenance procedures, such as checking for proper sensor alignment and ensuring electrical connections are secure, contribute to the sensor’s longevity and effectiveness 7.

Regulatory Compliance

The Cummins 4383979 Particulate Sensor aids heavy-duty trucks in meeting emissions regulations and standards set by environmental agencies. By accurately monitoring particulate matter in the exhaust, it allows for adjustments that help vehicles comply with these regulations, thereby supporting environmental protection efforts and ensuring legal operation 8.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a history of innovation and quality in the industry. The company’s commitment to advancing engine technology is evident in its development of components like the Cummins 4383979 Particulate Sensor, which plays a role in enhancing engine performance and emissions control in heavy-duty applications 9.

Cummins Particulate Sensor 4383979 Compatibility

The Cummins Particulate Sensor 4383979 is designed to be compatible with a range of Cummins engines, ensuring effective monitoring and management of particulate emissions. This sensor is integral to maintaining the performance and compliance of these engines with environmental regulations.

ISB6.7 CM2350 B101

The ISB6.7 CM2350 B101 engine benefits from the precise monitoring provided by the 4383979 Particulate Sensor. This engine, known for its robust performance, relies on accurate particulate measurement to optimize fuel efficiency and reduce emissions.

ISX12 CM2350 X102 and X15 CM2350 X116B

Both the ISX12 CM2350 X102 and X15 CM2350 X116B engines are equipped with the 4383979 Particulate Sensor. These engines, part of the CM2350 series, are designed for heavy-duty applications and require reliable particulate monitoring to ensure they meet stringent emission standards.

ISX15 CM2350 X101

The ISX15 CM2350 X101 engine also utilizes the 4383979 Particulate Sensor. This engine, known for its power and efficiency, depends on the sensor to maintain optimal performance and compliance with environmental regulations.

X12 CM2350 X119B and X15 CM2450 X134B

The X12 CM2350 X119B and X15 CM2450 X134B engines are equipped with the 4383979 Particulate Sensor. These engines, part of the CM2350 and CM2450 series respectively, are designed for various applications and benefit from the sensor’s ability to accurately measure particulate emissions, ensuring they operate within regulatory limits.

Role of Part 4383979 Particulate Sensor in Engine Systems

The 4383979 Particulate Sensor is an integral component in the monitoring and regulation of emissions within modern engine systems. It is strategically positioned within the aftertreatment device, where it plays a significant role in the overall efficiency and effectiveness of the aftertreatment system.

Integration with Aftertreatment Device

Within the aftertreatment device, the 4383979 Particulate Sensor works in conjunction with other components to ensure that emissions are kept within regulatory limits. The sensor provides real-time data on the levels of particulate matter, allowing the engine control unit (ECU) to make necessary adjustments to the fuel injection timing, exhaust gas recirculation (EGR) rates, and other parameters that influence emissions.

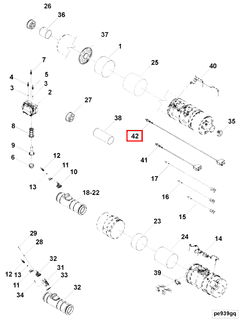

Interaction with Device and Aftertreatment Components

The sensor is mounted on a sensor bracket, which is, in turn, affixed to the device. This bracket not only secures the sensor in place but also ensures that it is positioned optimally to capture accurate readings. The data from the sensor is vital for the proper functioning of the aftertreatment components, such as the diesel particulate filter (DPF) and selective catalytic reduction (SCR) system.

The sensor’s readings help in determining when the DPF needs to undergo a regeneration process to burn off accumulated particulates. Similarly, it assists in the management of the SCR system by providing data that can influence the injection of urea (DEF) into the exhaust stream, ensuring that NOx levels are reduced effectively.

Overall System Synergy

The 4383979 Particulate Sensor, through its precise measurements and reliable data transmission, ensures that the aftertreatment device operates at peak efficiency. It contributes to a harmonious balance within the engine system, where each component—from the sensor bracket to the aftertreatment device—works in unison to achieve optimal performance and compliance with emissions standards.

Conclusion

The Cummins 4383979 Particulate Sensor is a critical component in the quest for cleaner and more efficient heavy-duty truck engines. By accurately monitoring particulate matter in the exhaust, it enables precise adjustments to engine parameters, ensuring compliance with emissions regulations and supporting environmental protection efforts. Its robust design, compatibility with various Cummins engines, and integration within the aftertreatment system underscore its importance in modern diesel engine technology.

-

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩ -

Haynes Manual on Diesel Engines, Martynn Randall, Haynes Publishing, 2015

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩ -

Owners Manual, QSF3.8 CM2350 F118, Bulletin Number 4388710

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩ -

Haynes Manual on Diesel Engines, Martynn Randall, Haynes Publishing, 2015

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.