This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4897501 Pressure Sensor is a component designed to monitor and measure pressure within the systems of commercial trucks. Its purpose is to provide accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor plays a significant role in ensuring that the truck’s systems perform optimally, thereby enhancing overall vehicle performance and reliability 1.

Basic Concepts of Pressure Sensors

A pressure sensor is a device that measures pressure exerted by gases or liquids. It operates by converting pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic systems. There are various types of pressure sensors, including absolute, gauge, differential, and compound sensors, each suited to different applications. These sensors are crucial in automotive systems for monitoring and controlling various functions such as fuel injection, turbocharging, and braking systems 2.

Purpose of the 4897501 Pressure Sensor

The 4897501 Pressure Sensor is specifically designed to monitor pressure levels within the truck’s systems. By providing precise pressure readings, it helps in maintaining the optimal performance of the engine and other critical systems. This sensor contributes to the truck’s overall efficiency by ensuring that systems operate within their designed parameters, thus preventing potential issues that could arise from incorrect pressure levels 3.

Key Features

The 4897501 Pressure Sensor boasts several key features that set it apart. Its design is robust, ensuring durability in the demanding environment of commercial trucking. The sensor is constructed with high-quality materials to withstand extreme conditions. Additionally, it features advanced technology that provides accurate and reliable pressure readings, enhancing the truck’s performance and safety 4.

Benefits

Utilizing the 4897501 Pressure Sensor in commercial trucks offers several benefits. It contributes to improved performance by ensuring systems operate efficiently. Enhanced safety is another advantage, as accurate pressure monitoring helps prevent system failures that could lead to accidents. Furthermore, the sensor increases efficiency by optimizing the operation of various truck systems, leading to better fuel economy and reduced maintenance costs 5.

Installation

Proper installation of the 4897501 Pressure Sensor is vital for its optimal performance. Guidelines for installation include ensuring the sensor is correctly positioned and securely fastened. It is also important to connect the sensor to the appropriate systems and verify that all connections are tight and secure. Correct installation ensures that the sensor can accurately monitor pressure levels and contribute to the truck’s efficient operation 6.

Troubleshooting

Common issues with the 4897501 Pressure Sensor may include inaccurate readings or sensor malfunction. Troubleshooting these problems involves checking the sensor’s connections, ensuring it is correctly installed, and verifying that there are no obstructions or damage to the sensor. Identifying and resolving malfunctions promptly helps maintain the sensor’s performance and the truck’s overall efficiency 7.

Maintenance

Regular maintenance of the 4897501 Pressure Sensor is recommended to ensure its longevity and reliable performance. This includes periodic checks to ensure the sensor is functioning correctly and calibrations to maintain accuracy. Proper maintenance helps prevent issues that could affect the sensor’s performance and the truck’s operation 8.

About Cummins

Cummins Inc. is a renowned manufacturer with a strong reputation in the automotive industry. The company is committed to quality and innovation, providing reliable and advanced components for various applications. Cummins’ dedication to excellence is evident in its wide range of products, including the 4897501 Pressure Sensor, which is designed to meet the high standards required for commercial trucking 9.

Pressure Sensor 4897501 Compatibility with Cummins Engines

The Pressure Sensor 4897501, manufactured by Cummins, is designed to integrate seamlessly with several of their engine models. This sensor plays a crucial role in monitoring and maintaining the operational efficiency of the engines by providing accurate pressure readings.

ISBE CM800

The ISBE CM800 engine benefits from the Pressure Sensor 4897501, which ensures precise pressure monitoring. This sensor is integral to the engine’s performance management system, helping to maintain optimal pressure levels and prevent potential issues that could arise from pressure fluctuations 10.

QSB4.5 CM850 (CM2850)

Similarly, the QSB4.5 CM850 (CM2850) engine incorporates the Pressure Sensor 4897501 to enhance its operational reliability. This sensor is essential for the engine’s diagnostic and control systems, ensuring that the engine operates within safe pressure parameters. Its integration into the QSB4.5 CM850 (CM2850) engine helps in maintaining consistent performance and longevity 11.

By utilizing the Pressure Sensor 4897501, both the ISBE CM800 and QSB4.5 CM850 (CM2850) engines can achieve enhanced monitoring and control, leading to improved efficiency and reduced risk of mechanical failures.

Role of Part 4897501 Pressure Sensor in Engine Systems

The part 4897501 Pressure Sensor is integral to the efficient operation of several key components within engine systems.

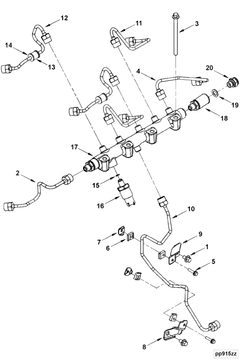

Fuel Manifold

In the fuel manifold, the pressure sensor monitors the pressure of the fuel as it is distributed to the various injectors. This ensures that each injector receives the correct amount of fuel, which is essential for maintaining the engine’s performance and fuel efficiency. The sensor provides real-time data that allows the engine control unit (ECU) to make necessary adjustments, ensuring optimal fuel delivery 12.

Injector Plumbing

Within the injector plumbing, the pressure sensor plays a vital role in maintaining consistent fuel pressure. It detects any fluctuations or irregularities in the fuel line, allowing the ECU to compensate and maintain stable fuel pressure. This is particularly important in high-performance engines where precise fuel delivery is required to achieve maximum power output and efficiency 13.

Plumbing

In the broader context of the engine’s plumbing system, the pressure sensor helps in diagnosing potential issues such as leaks or blockages. By continuously monitoring pressure levels, it provides valuable data that can alert mechanics to problems before they become severe, facilitating timely maintenance and repairs 14.

Injector

At the injector level, the pressure sensor ensures that each injector operates within its specified pressure range. This is essential for the injectors to atomize the fuel properly, which in turn enhances combustion efficiency and reduces emissions. The sensor’s data allows the ECU to fine-tune the injector’s operation, ensuring that it performs optimally under varying engine loads and conditions 15.

Conclusion

The Cummins 4897501 Pressure Sensor is a critical component in the maintenance and operation of commercial trucks. Its accurate pressure readings contribute to the efficient and safe operation of the vehicle, enhancing overall performance and reliability. Proper installation, regular maintenance, and prompt troubleshooting are essential to ensure the sensor’s optimal performance and longevity.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.