This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4903276 Pressure Sensor is designed to monitor and report pressure levels within commercial truck systems. It provides accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor is significant in commercial truck operations as it helps maintain optimal performance and ensures the longevity of the truck’s components by providing real-time data for adjustments and diagnostics 1.

Basic Concepts of Pressure Sensors

Pressure sensors measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can be interpreted by the vehicle’s electronic systems. These sensors are used in automotive systems to monitor various parameters such as fuel pressure, oil pressure, and air intake pressure. They ensure that the engine and other systems operate within their designed parameters, which is vital for performance and safety 2.

Role of the 4903276 Pressure Sensor in Truck Operation

The Cummins 4903276 Pressure Sensor is integrated into the truck’s systems to monitor specific pressure points. It provides data that is used by the truck’s electronic control unit (ECU) to make real-time adjustments to the engine and other systems. This sensor ensures that pressure levels are maintained at optimal levels, contributing to the engine’s efficiency and the overall performance of the vehicle 3.

Key Features of the 4903276 Pressure Sensor

The Cummins 4903276 Pressure Sensor is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. It is equipped with advanced technological specifications that enhance its performance, such as high accuracy in pressure readings and resistance to environmental factors that could affect its operation. These features contribute to the sensor’s ability to provide consistent and reliable data over time 4.

Benefits of Using the 4903276 Pressure Sensor

Incorporating the Cummins 4903276 Pressure Sensor into truck systems offers several advantages. It contributes to improved efficiency by ensuring that the engine operates under optimal conditions. It also enhances safety by providing accurate pressure readings that can be used to prevent potential issues before they become critical. Additionally, the sensor supports better maintenance practices by offering data that can be used for predictive maintenance, thereby reducing downtime and repair costs 1.

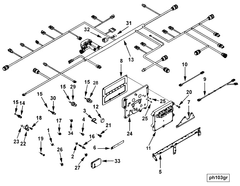

Installation and Integration

The installation of the Cummins 4903276 Pressure Sensor involves connecting it to the truck’s existing systems. This process may require modifications to ensure compatibility and optimal performance. It is important to follow the manufacturer’s guidelines to ensure that the sensor is properly integrated and that it operates as intended within the truck’s systems 2.

Troubleshooting and Maintenance

Common issues with the Cummins 4903276 Pressure Sensor may include inaccurate readings or failure to operate. Troubleshooting these issues involves checking the sensor’s connections, ensuring that it is properly installed, and verifying that there are no external factors affecting its operation. Regular maintenance, such as cleaning and inspecting the sensor, can help ensure its longevity and optimal performance. Signs of potential failure may include inconsistent pressure readings or warning lights on the truck’s dashboard 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various industries, including transportation, construction, and agriculture. Cummins’ commitment to excellence is reflected in its products, which are known for their reliability, performance, and durability 4.

Compatibility with Cummins Engines

The Pressure Sensor 4903276 is designed to integrate seamlessly with a variety of Cummins engine models. This sensor is crucial for monitoring and maintaining optimal engine performance by providing accurate pressure readings.

ISB/ISD6.7 CM2150 SN, ISBE4 CM850

The Pressure Sensor 4903276 is compatible with the ISB/ISD6.7 CM2150 SN and ISBE4 CM850 engines. This compatibility ensures that the sensor can effectively monitor the pressure levels within these engines, contributing to their overall efficiency and reliability.

ISM CM570/870, ISM CM876, ISX CM870

For the ISM CM570/870, ISM CM876, and ISX CM870 engines, the Pressure Sensor 4903276 is also a perfect fit. These engines benefit from the precise pressure monitoring capabilities of this sensor, which helps in maintaining optimal operational conditions and preventing potential issues.

QSC8.3 CM850 (CM2850)

Lastly, the Pressure Sensor 4903276 is compatible with the QSC8.3 CM850 (CM2850) engine. This compatibility ensures that the sensor can accurately measure pressure levels, providing essential data for the engine’s performance and maintenance.

Role of Part 4903276 Pressure Sensor in Engine Systems

The part 4903276 Pressure Sensor is an integral component in modern engine systems, working in conjunction with the Engine Control Module (ECM) to ensure optimal performance and efficiency.

Integration with Engine Control Module (ECM)

The Pressure Sensor 4903276 is designed to communicate directly with the ECM. It provides real-time data on various pressure parameters within the engine system. This data is essential for the ECM to make precise adjustments to fuel injection, ignition timing, and other critical functions.

Functionality in Engine Systems

-

Fuel System Regulation: The sensor monitors fuel pressure, allowing the ECM to maintain the correct fuel-to-air ratio. This ensures efficient combustion and reduces emissions.

-

Boost Pressure Monitoring: In turbocharged engines, the sensor measures the pressure in the intake tract. The ECM uses this information to control the turbocharger’s wastegate, optimizing boost levels for performance and safety.

-

Transmission Control: In vehicles with automatic transmissions, the sensor data assists the ECM in making smooth gear changes by providing information about hydraulic pressure within the transmission system.

-

Emission Control: By accurately measuring pressures within the exhaust system, the sensor helps the ECM to control the operation of emission control systems, such as the Exhaust Gas Recirculation (EGR) valve, ensuring compliance with environmental regulations.

-

Engine Protection: The sensor also plays a role in protecting the engine by alerting the ECM to abnormal pressure conditions that could indicate issues such as a failing turbocharger or a blocked fuel filter.

Conclusion

The Cummins 4903276 Pressure Sensor is a key component that enhances the functionality and reliability of engine systems through its precise pressure measurements and seamless integration with the ECM. Its robust design, high accuracy, and compatibility with various Cummins engines make it an essential part of modern commercial truck operations.

-

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ ↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ ↩ -

Reif, Konrad, ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ ↩ -

Lakshminarayanan, P. A., and Nayak, Nagaraj S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.