This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4921744 Pressure Sensor is a component designed to monitor and regulate pressure within the systems of commercial trucks. Its purpose is to ensure that the truck operates efficiently and safely by providing accurate pressure readings to the truck’s electronic control unit (ECU) 3. This sensor plays a role in maintaining optimal performance and reliability in commercial truck operations.

Basic Concepts of Pressure Sensors

A pressure sensor is a device that measures pressure exerted by gases or liquids. It operates by converting the physical pressure into an electrical signal, which can then be interpreted by the truck’s systems. The fundamental principles behind its functionality involve the use of a diaphragm that flexes under pressure, changing the electrical properties of a circuit and producing a measurable signal. This signal is then used to adjust various parameters within the truck’s systems to maintain desired performance levels 1.

Role of the 4921744 Pressure Sensor in Truck Operation

The Cummins 4921744 Pressure Sensor is integrated into the truck’s systems to monitor and regulate pressure in critical areas such as the fuel system, brake system, and engine components. By providing real-time data to the ECU, it allows for precise control of these systems, ensuring they operate within safe and efficient parameters. This integration enhances the overall performance and reliability of the truck 3.

Key Features of the 4921744 Pressure Sensor

The Cummins 4921744 Pressure Sensor is characterized by its robust design, which includes high-quality materials that ensure durability and accuracy. It incorporates advanced technological features such as a sensitive diaphragm and precise electronic components to deliver reliable pressure readings. Additionally, its compact design allows for easy integration into various truck systems without requiring significant modifications 3.

Benefits of Using the 4921744 Pressure Sensor

Utilizing the Cummins 4921744 Pressure Sensor offers several benefits, including improved performance, enhanced reliability, and increased efficiency in truck operations. Accurate pressure monitoring allows for better control of the truck’s systems, leading to smoother operation and reduced wear on components. This results in lower maintenance costs and extended component lifespan 3.

Installation and Integration

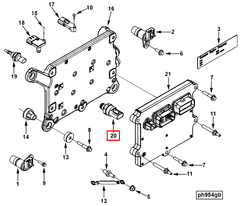

When installing the Cummins 4921744 Pressure Sensor, it is important to follow manufacturer guidelines to ensure proper integration into the truck’s systems. This involves connecting the sensor to the appropriate pressure points and ensuring it is securely mounted. Careful attention should be paid to wiring and connections to prevent any issues with signal transmission 3.

Troubleshooting Common Issues

Common issues with the Cummins 4921744 Pressure Sensor may include inaccurate readings or sensor failure. Troubleshooting steps involve checking connections for integrity, ensuring the sensor is correctly mounted, and verifying that the electrical system is functioning properly. If issues persist, consulting the manufacturer’s troubleshooting guide or seeking professional assistance may be necessary 3.

Maintenance Tips

Regular maintenance of the Cummins 4921744 Pressure Sensor is crucial for ensuring optimal performance and longevity. This includes periodic checks of connections and mounting, cleaning the sensor to remove any debris, and verifying that the electrical system is free from corrosion or damage. Adhering to a maintenance schedule helps prevent unexpected failures and ensures the sensor continues to provide accurate readings 3.

Impact on Fuel Efficiency

The Cummins 4921744 Pressure Sensor contributes to improved fuel efficiency in commercial trucks by enabling precise control of the fuel system. Accurate pressure monitoring allows for optimal fuel delivery, reducing waste and enhancing overall efficiency. This not only saves on fuel costs but also reduces the environmental impact of truck operations 2.

Safety Considerations

Safety is a paramount concern when using the Cummins 4921744 Pressure Sensor. Ensuring the sensor is properly installed and maintained helps prevent system failures that could lead to unsafe operating conditions. Additionally, following manufacturer guidelines and best practices for sensor use and maintenance contributes to the overall safety of truck operations 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins plays a significant role in the commercial truck industry. The company’s dedication to advancing technology and improving efficiency is evident in its range of products, including the Cummins 4921744 Pressure Sensor 3.

Compatibility with Cummins Engines

The Pressure Sensor part number 4921744, manufactured by Cummins, is designed to fit a variety of Cummins engines. This sensor plays a role in monitoring and maintaining the pressure levels within the engine’s systems, ensuring optimal performance and efficiency. Below is a detailed overview of the engines with which this pressure sensor is compatible:

- ISC CM850: The ISC CM850 engine benefits from the precise pressure monitoring capabilities of the 4921744 sensor, enhancing its operational reliability.

- ISL9 CM2150 SN: The ISL9 CM2150 SN engine is another beneficiary of the 4921744 pressure sensor, which helps in maintaining the necessary pressure levels for efficient engine performance.

- ISM CM570/870: The ISM CM570/870 engines are equipped with the 4921744 pressure sensor to ensure that pressure readings are accurate, contributing to the engine’s overall health and longevity.

- ISM CM876: The ISM CM876 engine utilizes the 4921744 pressure sensor to monitor and regulate pressure, which is vital for its performance and efficiency.

- ISX CM870 and ISX CM871: Both the ISX CM870 and ISX CM871 engines are compatible with the 4921744 pressure sensor. This sensor provides data for maintaining optimal pressure levels, ensuring these high-performance engines run smoothly.

- QSB5.9 CM850: The QSB5.9 CM850 engine also integrates the 4921744 pressure sensor, which is important for its pressure monitoring needs.

- QSC8.3 CM850 (CM2850): The QSC8.3 CM850 (CM2850) engine is another model that uses the 4921744 pressure sensor to ensure accurate pressure readings, contributing to its operational efficiency.

- QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850): The QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850) engines are also compatible with the 4921744 pressure sensor. This sensor is integral to maintaining the necessary pressure levels for these engines to function correctly.

By ensuring that the 4921744 pressure sensor is correctly installed and functioning, these Cummins engines can maintain optimal performance, efficiency, and reliability 3.

Role of Part 4921744 Pressure Sensor in Engine Systems

The Part 4921744 Pressure Sensor is an integral component in modern engine systems, working in conjunction with the Engine Control Module (ECM) to ensure optimal engine performance and efficiency.

Integration with the Engine Control Module (ECM)

The Pressure Sensor continuously monitors the pressure levels within the engine system. It sends real-time data to the ECM, which uses this information to make precise adjustments to fuel injection, ignition timing, and other critical parameters. This dynamic feedback loop allows the ECM to maintain the engine’s performance under varying conditions, ensuring smooth operation and efficient fuel consumption 3.

Enhancing Engine Performance

By providing accurate pressure readings, the Pressure Sensor enables the ECM to fine-tune the air-fuel mixture. This results in improved combustion efficiency, reduced emissions, and enhanced overall engine performance. The sensor’s ability to detect even minor fluctuations in pressure ensures that the engine operates within its optimal range, prolonging its lifespan and reliability 3.

Supporting Diagnostic Functions

The data collected by the Pressure Sensor is also vital for diagnostic purposes. When the ECM detects anomalies in the pressure readings, it can trigger warning signals or store diagnostic trouble codes (DTCs). This facilitates quicker and more accurate troubleshooting, allowing mechanics to identify and address issues before they escalate into more significant problems 3.

Contribution to Fuel Efficiency

Efficient fuel management is another area where the Pressure Sensor plays a role. By ensuring that the air-fuel ratio is consistently optimal, the sensor helps minimize fuel waste. This not only reduces operating costs but also contributes to a lower environmental impact by decreasing the amount of unburned fuel released into the atmosphere 2.

Ensuring Safety and Reliability

Accurate pressure monitoring is essential for the safe and reliable operation of engine systems. The Pressure Sensor helps prevent issues such as engine knocking, which can occur if the air-fuel mixture is too lean or too rich. By providing the ECM with reliable data, the sensor contributes to a stable and predictable engine performance, enhancing both safety and driver confidence 3.

Conclusion

The Cummins 4921744 Pressure Sensor is a critical component in the operation of commercial trucks and Cummins engines. Its role in monitoring and regulating pressure ensures optimal performance, efficiency, and reliability. By integrating with the ECM, enhancing engine performance, supporting diagnostic functions, contributing to fuel efficiency, and ensuring safety and reliability, this part plays a vital role in modern engine systems.

-

Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, Wilfried J Bartz, CRC Press, 2019.

↩ -

Engine ISB5.9 CM2880 B149, Bulletin Number 5467239, Owners Manual.

↩ ↩ -

Fundamentals of Automotive Technology Principles and Practice, Kirk T Van Gelder, Jones Bartlett Learning, 2018.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.