This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4927802 Pressure Sensor is designed to monitor and regulate pressure within commercial truck systems. It ensures efficient and reliable truck operation by providing accurate pressure readings for real-time system adjustments 1.

Basic Concepts of Pressure Sensors

Pressure sensors measure the force exerted by a fluid on a surface, converting this pressure into an electrical signal. In automotive applications, they are used in fuel injection, brake systems, and engine management to ensure systems function within specified parameters 2.

Functionality of the Cummins 4927802 Pressure Sensor

This Cummins part detects pressure changes within the truck’s systems and converts them into electrical signals. These signals are sent to the truck’s electronic control unit (ECU), which uses the data to make necessary adjustments, ensuring efficient engine and system operation 3.

Role in Truck Operation

The Cummins 4927802 Pressure Sensor is integrated with the truck’s electronic control systems, providing real-time data on system pressures. This allows the ECU to make adjustments for optimal performance, ensuring systems operate within designed parameters 4.

Key Features

This part is characterized by high accuracy in pressure readings, durability to withstand harsh commercial truck conditions, and compatibility with Cummins engines. These features ensure reliable data and performance under demanding conditions 5.

Benefits of Using the Cummins 4927802 Pressure Sensor

Using this part offers advantages such as improved performance through efficient system operation, enhanced vehicle reliability with accurate pressure readings for timely adjustments, and seamless integration with Cummins engines 6.

Installation and Integration

Proper installation and integration of this part within a truck’s system are crucial for effective operation. It should be installed according to manufacturer guidelines for accurate readings and reliable performance, integrating with the truck’s electronic control systems for real-time monitoring and adjustment of system pressures 7.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting of the Cummins 4927802 Pressure Sensor are recommended to ensure optimal performance. This includes checking for wear or damage, ensuring proper connections, and calibrating the sensor as needed to prevent significant problems and ensure accurate readings 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry, offering a wide range of products designed to meet various industry needs 9.

Cummins Pressure Sensor 4927802 Compatibility

The Cummins Pressure Sensor part number 4927802 is designed to integrate seamlessly with a variety of Cummins engines, ensuring precise monitoring and regulation of pressure within the engine systems. This sensor is crucial for maintaining optimal engine performance and efficiency.

K38 and K50 Engines

The 4927802 Pressure Sensor is specifically engineered to fit the K38 and K50 engines. These engines are part of Cummins’ robust lineup, known for their reliability and performance in various applications. The sensor’s compatibility with these engines ensures that it can effectively communicate with the engine control unit (ECU), providing real-time data that helps in adjusting engine parameters for optimal operation 10.

Integration and Functionality

When installed in the K38 and K50 engines, the 4927802 Pressure Sensor is typically positioned in a location that allows it to accurately measure the pressure within the engine’s system. This placement is critical for ensuring that the sensor can detect any fluctuations in pressure that may indicate potential issues such as leaks, blockages, or other mechanical problems.

The sensor works by converting the pressure readings into electrical signals that are sent to the ECU. The ECU then processes this information and makes necessary adjustments to maintain the engine’s performance and efficiency. This seamless integration ensures that the engine operates smoothly and reliably, reducing the risk of unexpected downtime and maintenance issues 11.

Importance of Proper Installation

Proper installation of the 4927802 Pressure Sensor is essential for its effective operation. Technicians should follow the manufacturer’s guidelines to ensure that the sensor is correctly positioned and securely mounted. This will help in achieving accurate readings and maintaining the integrity of the engine’s pressure monitoring system.

By ensuring that the 4927802 Pressure Sensor is correctly installed and integrated with the K38 and K50 engines, operators can benefit from enhanced engine performance, improved fuel efficiency, and reduced maintenance costs. This sensor is a vital component in the overall health and longevity of these engines, making it a critical part of the engine’s diagnostic and monitoring system 12.

Role of Part 4927802 Pressure Sensor in Engine Systems

The part 4927802 Pressure Sensor is integral to the operation and monitoring of various engine systems. It provides essential data that contributes to the overall performance and safety of the engine.

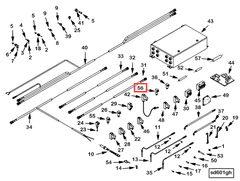

Integration with the Panel

When integrated into the panel, the 4927802 Pressure Sensor offers real-time pressure readings. These readings are displayed on the panel, allowing operators to monitor pressure levels continuously. This ensures that any deviations from normal operating conditions are immediately visible, enabling prompt action to be taken 13.

Contribution to Engine Instruments

In the context of engine instruments, the 4927802 Pressure Sensor plays a significant role by providing accurate pressure data. This data is used by various instruments to calculate and display parameters such as fuel pressure, oil pressure, and turbo boost pressure. Accurate pressure readings are essential for the precise functioning of these instruments, ensuring that the engine operates within safe limits 14.

Role in the System

Within the broader engine system, the 4927802 Pressure Sensor contributes to the overall health and efficiency of the engine. It works in conjunction with other sensors and control units to maintain optimal pressure levels. This is particularly important in systems where pressure regulation is key to performance, such as fuel injection systems and hydraulic systems 15.

Importance in Engine Monitoring

Engine monitoring systems rely heavily on the data provided by the 4927802 Pressure Sensor. By continuously monitoring pressure levels, these systems can detect anomalies and potential issues before they become serious problems. This proactive approach to engine maintenance helps in preventing breakdowns and extending the lifespan of the engine 16.

Conclusion

The Cummins 4927802 Pressure Sensor is a vital component that enhances the functionality and reliability of engine systems through accurate pressure monitoring and data provision. Its integration into various engine systems ensures optimal performance, safety, and efficiency, making it an indispensable part of modern commercial truck operations.

-

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). ISF2.8 CM2220 F117, Bulletin Number 4388579, Operation and Maintenance Manual.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). ISF2.8 CM2220 F117, Bulletin Number 4388579, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). ISF2.8 CM2220 F117, Bulletin Number 4388579, Operation and Maintenance Manual.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). ISF2.8 CM2220 F117, Bulletin Number 4388579, Operation and Maintenance Manual.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.