This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4954185 Pressure Sensor is a component designed to monitor and measure pressure levels within the systems of commercial trucks. Its purpose is to provide accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor is integral to maintaining optimal performance and ensuring that the truck’s systems operate within specified parameters 1.

Basic Concepts of Pressure Sensors

A pressure sensor is a device that measures pressure exerted by gases or liquids. It converts this physical pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic control systems. Pressure sensors are utilized in various automotive applications, including engine management, brake systems, and fuel delivery systems, to ensure that these components function correctly under varying conditions 3.

Function and Role in Truck Operation

The Cummins 4954185 Pressure Sensor plays a role in the operation of a commercial truck by providing real-time pressure data to the truck’s electronic control unit (ECU). This data is used to make adjustments to the engine and other systems, ensuring that they operate efficiently and within safe limits. The sensor is integrated into the truck’s systems, where it monitors pressure levels and sends this information to the ECU for processing 1.

Key Features

The Cummins 4954185 Pressure Sensor is characterized by its robust design, which includes high-quality materials that ensure durability and reliability in demanding environments. The sensor is equipped with advanced technological specifications that allow for precise pressure measurements. Its construction is tailored to withstand the harsh conditions often encountered in commercial truck operations 1.

Benefits of Using the 4954185 Pressure Sensor

The advantages provided by the Cummins 4954185 Pressure Sensor include enhanced performance and efficiency of the truck’s systems. By providing accurate pressure readings, the sensor contributes to the overall safety of the vehicle, helping to prevent issues that could arise from incorrect pressure levels. Additionally, the sensor’s reliable operation helps to reduce the likelihood of system failures, leading to improved uptime for the truck 1.

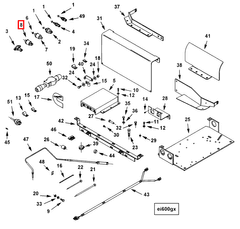

Installation and Integration

When installing the Cummins 4954185 Pressure Sensor, it is important to follow guidelines that ensure proper integration into the truck’s system. This may involve making necessary preparations or adjustments to the system to accommodate the sensor. Careful attention to these details helps to ensure that the sensor functions correctly and provides accurate readings 1.

Troubleshooting Common Issues

Common problems that may arise with the Cummins 4954185 Pressure Sensor include inaccurate readings or sensor failure. Troubleshooting steps may involve checking the sensor’s connections, ensuring that it is properly installed, and verifying that the sensor is compatible with the truck’s system. In some cases, replacing the sensor may be necessary to resolve the issue 1.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4954185 Pressure Sensor, regular maintenance is recommended. This may include cleaning the sensor to remove any debris that could affect its readings, checking its connections for signs of wear or corrosion, and ensuring that it remains properly calibrated. Adhering to these maintenance practices helps to maintain the sensor’s accuracy and reliability 1.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a diverse product range, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and performance is reflected in its products, including the Cummins 4954185 Pressure Sensor 2.

Cummins Pressure Sensor 4954185 Compatibility

The Cummins Pressure Sensor 4954185 is designed to monitor and regulate pressure within the engine systems of various Cummins engines. This sensor plays a pivotal role in ensuring optimal engine performance and efficiency by providing real-time data to the engine control unit (ECU).

K38 and K50 Engines

The Pressure Sensor 4954185 is compatible with both the K38 and K50 engines, which are part of Cummins’ extensive lineup of industrial and heavy-duty engines. These engines are known for their robust construction and reliability, making them suitable for a wide range of applications, from construction equipment to marine vessels.

K38 Engine

In the K38 engine, the Pressure Sensor 4954185 is integral to the engine’s fuel injection system. It ensures that the fuel is injected at the correct pressure, which is crucial for maintaining the engine’s power output and fuel efficiency. The sensor’s precise measurements help in preventing issues such as over-fueling or under-fueling, which can lead to engine performance degradation and increased emissions.

K50 Engine

Similarly, in the K50 engine, the Pressure Sensor 4954185 is essential for the engine’s overall performance. It works in conjunction with the engine’s ECU to monitor and adjust the pressure levels within the engine’s combustion chambers. This ensures that the engine operates at peak efficiency, providing the necessary power while maintaining low emissions and fuel consumption.

By integrating seamlessly with both the K38 and K50 engines, the Cummins Pressure Sensor 4954185 underscores Cummins’ commitment to delivering high-quality, reliable engine components that enhance the performance and longevity of their engines 2.

Role of Part 4954185 Pressure Sensor in Engine Systems

Part 4954185, a Pressure Sensor, is integral to the operation of several key components within engine systems. When integrated into the Coolant Pressure Sensor, it provides precise measurements of coolant pressure, ensuring optimal engine temperature management. This sensor’s accurate readings enable the Electronic Engine Control Unit (ECU) to adjust engine parameters dynamically, enhancing performance and efficiency 3.

In the broader Engine Monitoring System, the pressure sensor plays a pivotal role by continuously providing data that is vital for maintaining engine health. It helps in detecting anomalies early, allowing for timely interventions that prevent potential failures. The sensor’s ability to deliver consistent and reliable pressure readings ensures that the engine operates within safe parameters, contributing to longevity and reliability 3.

Furthermore, the integration of this pressure sensor within the Engine Monitoring System facilitates comprehensive diagnostics. Engineers and mechanics can utilize the data to perform detailed analyses of engine behavior under various conditions, leading to informed decisions regarding maintenance and upgrades. This proactive approach to engine management is essential for maximizing uptime and minimizing unexpected downtimes 3.

Conclusion

The Cummins 4954185 Pressure Sensor is a critical component in the efficient and safe operation of commercial trucks. Its role in providing accurate pressure readings to the truck’s electronic control unit ensures that the engine and other systems operate within optimal parameters. The sensor’s robust design, precise measurements, and reliable operation contribute to enhanced performance, safety, and uptime for the vehicle. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this Cummins part.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ ↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.