This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

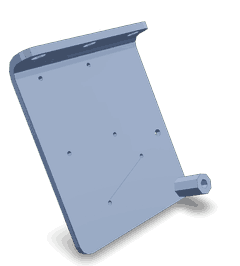

The Cummins 4969400 Sensor Bracket is a component designed for use in commercial trucks, specifically within the engine system. A sensor bracket serves as a mounting point for various sensors, ensuring they are securely positioned and correctly oriented to function effectively. This bracket plays a role in maintaining the structural integrity of the sensor setup and contributes to the overall performance and reliability of the truck’s engine system 1.

Purpose and Function

The Cummins 4969400 Sensor Bracket is designed to support the mounting and stabilization of sensors within the truck’s engine system. It ensures that sensors are held in precise locations, which is vital for obtaining accurate readings. Accurate sensor data is essential for the engine control unit (ECU) to make informed decisions regarding fuel injection, ignition timing, and other engine operations. The bracket contributes to maintaining system integrity by providing a stable platform for sensors, thereby enhancing the reliability of engine performance 2.

Key Features

The Cummins 4969400 Sensor Bracket is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions often encountered in commercial trucking environments. Its design includes features such as corrosion-resistant coatings and robust mounting points, which enhance its performance and longevity. These characteristics ensure that the bracket can withstand vibrations and temperature fluctuations, maintaining its structural integrity over time 3.

Benefits

The Cummins 4969400 Sensor Bracket offers several benefits that contribute to the reliability and efficiency of the truck’s engine system. Improved sensor accuracy leads to better engine performance and fuel efficiency. The bracket’s durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, its design allows for ease of installation, minimizing downtime during maintenance procedures.

Installation and Compatibility

Proper installation of the Cummins 4969400 Sensor Bracket is vital for ensuring its effectiveness. It is compatible with various Cummins engine models, and installation guidelines should be followed to ensure correct placement and secure mounting. Step-by-step instructions are available to assist with the installation process, ensuring that the bracket is properly aligned and fastened.

Troubleshooting and Maintenance

Common issues with sensor brackets may include misalignment, corrosion, or physical damage. Regular maintenance and periodic inspections can help identify and address these issues before they lead to more significant problems. Maintenance tips include checking for signs of wear or corrosion, ensuring that mounting points are secure, and verifying that sensors are correctly aligned.

Role in Engine Performance

The Cummins 4969400 Sensor Bracket plays a role in overall engine performance by ensuring that sensors are accurately positioned and securely mounted. This accuracy is crucial for the engine control unit to receive reliable data, which it uses to optimize fuel consumption, ignition timing, and emission control. The interplay between sensor brackets and engine efficiency highlights the importance of this component in maintaining optimal engine operation.

Safety Considerations

Proper installation and maintenance of the sensor bracket are important for safety. A malfunctioning or improperly installed sensor bracket can lead to inaccurate sensor readings, which may result in suboptimal engine performance or even engine damage. Regular inspections and adherence to installation guidelines help mitigate these risks, ensuring the continued safe and efficient operation of the vehicle.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in the commercial truck industry. With a rich history of providing reliable and high-performance engine components, Cummins continues to be a trusted name in the field. The company’s dedication to excellence is evident in its product line, including the Cummins 4969400 Sensor Bracket, which exemplifies Cummins’ focus on durability, performance, and customer satisfaction.

Sensor Bracket 4969400 Compatibility with Cummins Engines

The Sensor Bracket part number 4969400, manufactured by Cummins, is designed to fit seamlessly with specific engine models. This bracket is essential for securing sensors in place, ensuring they maintain optimal positioning and functionality throughout the engine’s operation.

For the QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines, the Sensor Bracket 4969400 is engineered to integrate smoothly with the engine’s architecture. This compatibility ensures that the bracket provides the necessary support for sensors, maintaining their alignment and operational integrity.

The precision engineering of this bracket guarantees a secure fit, minimizing the risk of sensor misalignment or detachment, which could lead to performance issues or engine malfunctions. By using the Sensor Bracket 4969400, technicians and operators can trust that their sensors will remain properly positioned, contributing to the overall reliability and efficiency of the engines.

Role of Part 4969400 Sensor Bracket in Engine Systems

The 4969400 Sensor Bracket is an integral component in the assembly and functionality of engine monitoring systems. This bracket securely mounts various sensors that are essential for monitoring the engine’s performance and ensuring optimal operation.

In the context of an engine monitoring system, the sensor bracket provides a stable platform for sensors such as the Manifold Absolute Pressure (MAP) sensor, the Mass Air Flow (MAF) sensor, and the Oxygen (O2) sensor. These sensors collect vital data on air pressure, air flow rate, and oxygen levels within the engine, respectively.

The accurate placement and secure mounting offered by the 4969400 Sensor Bracket ensure that these sensors can operate effectively without being subjected to vibrations or movement that could compromise data accuracy. This, in turn, allows the Engine Control Unit (ECU) to make precise adjustments to fuel injection, ignition timing, and other critical parameters, enhancing overall engine efficiency and performance.

Additionally, the sensor bracket facilitates easy access for maintenance and calibration of these sensors, which is essential for the longevity and reliability of the engine monitoring system. Its design also allows for straightforward integration with other components, such as wiring harnesses and sensor connectors, ensuring a seamless installation process.

Conclusion

In summary, the Cummins 4969400 Sensor Bracket plays a significant role in maintaining the integrity and functionality of engine monitoring systems by providing a robust and reliable mounting solution for essential sensors. Its durable construction, ease of installation, and compatibility with various Cummins engine models make it a vital component for ensuring optimal engine performance and reliability.

-

Automotive Systems Principles and Practice, G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, CRC Press, 2011.

↩ -

Vehicle Dynamics: Theory and Application, Reza N. Jazar, Springer, 2017.

↩ -

Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, John Dixon, Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.