This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

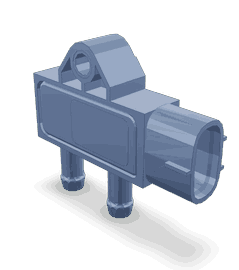

The Cummins 4984699 Differential Pressure Sensor is designed to monitor and measure the pressure differential between two points in a system. This sensor is integral to the operation of commercial trucks, providing data that helps maintain optimal performance and efficiency. By accurately measuring pressure differences, it assists in the regulation of various systems within the truck, contributing to overall vehicle functionality.

Basic Concepts of Differential Pressure Sensors

A differential pressure sensor measures the difference in pressure between two points. It operates by using a diaphragm that flexes in response to pressure differences, converting this mechanical movement into an electrical signal. This signal is then processed by the vehicle’s electronic control unit (ECU) to make adjustments as necessary. Differential pressure sensors are commonly used in automotive systems for applications such as monitoring air filter efficiency, regulating turbocharger boost pressure, and managing exhaust gas recirculation (EGR) systems 1.

Role of the 4984699 Differential Pressure Sensor in Truck Operation

The Cummins 4984699 Differential Pressure Sensor monitors the pressure differential across the diesel particulate filter (DPF). This measurement is vital for assessing the filter’s condition and ensuring it operates within specified parameters. The sensor’s data allows the truck’s ECU to initiate regeneration processes when necessary, helping to maintain the DPF’s efficiency and prolong its lifespan. Integration of this sensor into the truck’s systems enhances overall performance and compliance with emissions regulations 2.

Key Features of the 4984699 Differential Pressure Sensor

The Cummins 4984699 Differential Pressure Sensor is characterized by its robust design and high-quality materials, ensuring durability and reliability in demanding truck environments. Technological advancements incorporated into this sensor include precise measurement capabilities and resistance to environmental factors such as temperature variations and vibrations. These features contribute to the sensor’s performance and longevity, making it a reliable component for commercial truck applications 3.

Benefits of Using the 4984699 Differential Pressure Sensor

Utilizing the Cummins 4984699 Differential Pressure Sensor offers several advantages. It contributes to improved engine performance by ensuring the DPF operates efficiently, which in turn supports better airflow and combustion. Enhanced fuel efficiency is another benefit, as optimal DPF function reduces backpressure and allows the engine to operate more effectively. Additionally, the sensor’s accurate monitoring capabilities contribute to overall system reliability, helping to prevent issues related to particulate filter clogging and ensuring compliance with emissions standards.

Installation and Integration

Proper installation of the Cummins 4984699 Differential Pressure Sensor involves connecting it to the appropriate points in the truck’s exhaust system, typically before and after the DPF. It is important to follow manufacturer guidelines to ensure accurate placement and secure mounting. Integration into the truck’s system requires calibration of the sensor with the ECU to ensure it operates within the specified parameters. This process may involve software updates or adjustments to the ECU settings to accommodate the sensor’s data.

Troubleshooting Common Issues

Common problems associated with differential pressure sensors include inaccurate readings, sensor malfunctions, and electrical issues. Potential causes for these problems can range from physical damage to the sensor, contamination of the sensing element, to issues within the electrical circuit. Recommended troubleshooting steps include inspecting the sensor for physical damage, cleaning or replacing the sensor if contamination is detected, and checking the electrical connections for integrity and proper function.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4984699 Differential Pressure Sensor, regular maintenance practices are recommended. These include periodic inspection of the sensor for signs of wear or damage, ensuring the electrical connections are secure and free from corrosion, and following the manufacturer’s guidelines for any required calibration or testing. Additionally, maintaining the overall health of the truck’s exhaust system, including regular DPF servicing, can contribute to the sensor’s effective operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a prominent player in the commercial truck industry, offering a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s commitment to innovation, quality, and customer satisfaction has solidified its reputation as a trusted provider of automotive and industrial solutions.

Differential Pressure Sensor 4984699 in Cummins Engines

The Differential Pressure Sensor 4984699, manufactured by Cummins, is a critical component in several of their engine models, ensuring optimal performance and efficiency. This sensor is integral to the engine’s operation, particularly in the KTA38GC CM558 series, where it plays a pivotal role in maintaining the balance and efficiency of the engine’s systems.

In the KTA38GC CM558 engines, the Differential Pressure Sensor 4984699 is designed to monitor the pressure differential across various components. This monitoring is crucial for the engine’s turbocharger system, where it helps in regulating the boost pressure. By accurately measuring the pressure differential, the sensor ensures that the turbocharger operates within the optimal range, preventing over-boosting and under-boosting scenarios that could lead to engine damage or reduced performance.

The integration of the Differential Pressure Sensor 4984699 in the KTA38GC CM558 engines is seamless, thanks to Cummins’ engineering expertise. The sensor is strategically placed in the engine’s system to provide real-time data to the engine control unit (ECU). This data is then used by the ECU to make necessary adjustments to the engine’s operation, ensuring that the engine runs smoothly and efficiently.

The use of the Differential Pressure Sensor 4984699 in the KTA38GC CM558 engines underscores Cummins’ commitment to providing high-quality, reliable components that enhance engine performance. This sensor is a testament to Cummins’ dedication to innovation and precision in engine design, ensuring that their engines meet the highest standards of performance and durability.

Role of Part 4984699 Differential Pressure Sensor in Engine Systems

The differential pressure sensor, part 4984699, is an integral component in modern engine systems, working in conjunction with the engine control module (ECM) to optimize performance and efficiency.

Integration with the Engine Control Module

The ECM relies on precise data to manage various engine functions. The differential pressure sensor provides real-time data on pressure differences across specific points in the engine system. This data allows the ECM to make informed adjustments to fuel injection, air-fuel ratio, and other critical parameters.

Enhancing Engine Performance

By continuously monitoring pressure differentials, the sensor helps the ECM detect any irregularities or inefficiencies within the engine. This proactive monitoring enables the ECM to implement corrective actions, such as adjusting the fuel delivery or modifying the air intake, ensuring the engine operates within optimal parameters.

Supporting Emission Control Systems

In addition to performance optimization, the differential pressure sensor plays a role in emission control systems. Accurate pressure readings help the ECM manage the exhaust gas recirculation (EGR) system more effectively, reducing harmful emissions and ensuring compliance with environmental regulations.

Facilitating Diagnostic Processes

The data from the differential pressure sensor is invaluable during diagnostic processes. When the ECM receives abnormal pressure readings, it can trigger warning lights or store diagnostic trouble codes (DTCs), alerting mechanics to potential issues before they escalate into more significant problems.

Conclusion

In summary, the Cummins 4984699 Differential Pressure Sensor is a key component that enhances the functionality and efficiency of engine systems by providing essential data to the ECM. Its role in performance optimization, emission control, and diagnostics underscores its importance in modern automotive engineering.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Owen C Duffy and Gus Wright, Jones Bartlett Learning, 2016.

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.