This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

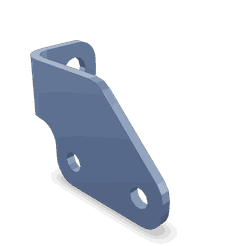

The 4999044 Sensor Mounting Bracket, a component manufactured by Cummins, is designed specifically for use in commercial trucks. This part plays a role in the operation of these vehicles by securely holding sensors in place, ensuring they function correctly. Cummins, a well-established manufacturer in the automotive industry, is known for producing reliable and high-quality parts that contribute to the efficient operation of commercial trucks 1.

Basic Concepts of Sensor Mounting Brackets

A Sensor Mounting Bracket is a structural component used in vehicles to support and position sensors. These brackets are integral to the vehicle’s system as they ensure sensors are correctly aligned and securely fastened. This allows sensors to accurately monitor various parameters such as temperature, pressure, and other metrics. The proper functioning of these sensors is dependent on their stable and precise placement, which is facilitated by the mounting bracket 2.

Purpose of the 4999044 Sensor Mounting Bracket

This Cummins part provides a stable platform for sensors, ensuring that they are correctly positioned to interact with other systems within the truck. This interaction is crucial for the accurate collection of data, which is then used by the truck’s systems to make adjustments and maintain optimal performance. The bracket’s design allows for easy sensor integration and replacement, enhancing the overall efficiency of the truck’s monitoring and diagnostic systems.

Key Features

The 4999044 Sensor Mounting Bracket is constructed from durable materials, ensuring longevity and resistance to the harsh conditions often encountered in commercial trucking. The design of the bracket includes precise mounting points that allow for secure sensor attachment. Additionally, the bracket may feature unique attributes such as corrosion resistance and ease of installation, which contribute to its effectiveness in maintaining sensor stability and accuracy.

Benefits

The use of the 4999044 Sensor Mounting Bracket offers several benefits. It provides improved sensor stability, which is crucial for accurate data collection. The enhanced durability of the bracket ensures long-term performance, reducing the need for frequent replacements. Furthermore, the bracket can contribute to improved truck performance and diagnostics by ensuring sensors operate within optimal conditions. This can lead to more efficient truck operation and potentially lower maintenance costs.

Installation Process

Installing the 4999044 Sensor Mounting Bracket requires careful attention to ensure proper sensor alignment and secure fastening. The process involves identifying the correct location for the bracket, aligning it with the sensor, and using the appropriate tools to fasten it in place. It is important to follow the manufacturer’s guidelines to ensure the bracket is installed correctly and functions as intended.

Troubleshooting Common Issues

Common issues with Sensor Mounting Brackets may include sensor misalignment, bracket loosening, or damage to the bracket itself. These problems can often be traced back to improper installation, wear and tear, or exposure to extreme conditions. Troubleshooting steps may involve realigning the sensor, tightening or replacing fasteners, or inspecting the bracket for damage and replacing it if necessary.

Maintenance Tips

Regular maintenance of the 4999044 Sensor Mounting Bracket is important to ensure its longevity and optimal performance. This includes periodic inspections to check for signs of wear, corrosion, or damage. Cleaning the bracket and its surrounding area can prevent the buildup of debris that may interfere with sensor operation. Following these maintenance tips can help maintain the bracket’s effectiveness and contribute to the overall reliability of the truck’s sensor systems.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the automotive industry. Known for their high-quality products, Cummins offers a wide range of components designed for commercial trucks. Their commitment to innovation and reliability has established them as a trusted name in the industry, providing parts that contribute to the efficient and safe operation of commercial vehicles 3.

Cummins Sensor Mounting Bracket 4999044 Compatibility

The Cummins Sensor Mounting Bracket 4999044 is designed to be compatible with a range of Cummins engines, ensuring a secure and reliable mounting solution for various sensors. This bracket is engineered to fit seamlessly with the following engines:

-

QSK60: This engine is part of Cummins’ QSK series, known for its robust performance and reliability in heavy-duty applications. The 4999044 bracket is specifically tailored to the QSK60’s design, providing a precise fit for sensor mounting.

-

CM850: The CM850 engine is another high-performance model from Cummins, often used in industrial and marine applications. The 4999044 bracket is engineered to align perfectly with the CM850’s architecture, ensuring that sensors are mounted securely and accurately.

-

MCRS: The MCRS engine is a versatile model used in a variety of applications, from construction equipment to marine vessels. The 4999044 bracket is designed to fit the MCRS engine, providing a reliable mounting solution for sensors that is both durable and precise.

These engines, while differing in specific applications and configurations, share a common requirement for reliable sensor mounting. The 4999044 bracket is designed to meet this requirement across the QSK60, CM850, and MCRS engines, ensuring that sensors are mounted securely and accurately, regardless of the engine model.

Role of Part 4999044 Sensor Mounting Bracket in Engine Systems

The 4999044 Sensor Mounting Bracket is an integral component in the assembly and operation of various engine systems. It provides a secure and stable platform for sensors that are essential for monitoring and controlling engine performance.

In the context of an Instrument system, the Sensor Mounting Bracket ensures that sensors are positioned accurately to gather precise data on parameters such as temperature, pressure, and emissions. This data is vital for the instrument panel to display real-time information to the operator, allowing for informed decision-making and timely adjustments.

Within the Engine system, the bracket plays a significant role in maintaining the integrity and functionality of sensors that monitor critical aspects like fuel injection, air-fuel ratio, and engine temperature. By securely holding these sensors in place, the bracket helps ensure that the engine control unit (ECU) receives accurate readings, which are essential for optimal engine performance and efficiency.

Additionally, the Sensor Mounting Bracket contributes to the overall reliability of the engine system by protecting sensors from vibrations and physical damage, thereby enhancing the durability and accuracy of the sensor readings. This, in turn, supports the engine’s ability to operate smoothly and efficiently under varying conditions.

Conclusion

The 4999044 Sensor Mounting Bracket is a crucial component in the operation of commercial trucks, ensuring sensors are securely mounted and accurately positioned. Its durable construction, ease of installation, and compatibility with various Cummins engines make it a reliable choice for maintaining the efficiency and performance of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.