This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5260246 Pressure Sensor is a component designed to monitor and regulate various pressure levels within the engine management system of commercial trucks. Its role is significant as it contributes to the overall efficiency, performance, and reliability of the vehicle. By providing accurate pressure readings, this sensor helps ensure that the engine operates within optimal parameters, enhancing both fuel efficiency and longevity of the engine components 2.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic control unit (ECU). These sensors are integral to various automotive systems, including fuel injection, brake systems, and engine management, where precise pressure monitoring is necessary for optimal performance 1.

Purpose of the Cummins 5260246 Pressure Sensor

The Cummins 5260246 Pressure Sensor is specifically designed to monitor pressure levels within the engine management system of commercial trucks. It plays a role in ensuring that the engine operates efficiently by providing the ECU with real-time pressure data. This information allows the ECU to make necessary adjustments to fuel injection, air intake, and other critical functions, thereby maintaining optimal engine performance and fuel efficiency 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, which ensure durability and reliability in demanding environments. It incorporates advanced technological specifications that enhance its accuracy and responsiveness. The sensor is engineered to withstand the harsh conditions typical of commercial truck operations, including extreme temperatures and vibrations 2.

Benefits of Using the Cummins 5260246 Pressure Sensor

Utilizing the Cummins 5260246 Pressure Sensor offers several advantages. It contributes to improved engine performance by ensuring that the engine operates within optimal pressure parameters. This results in enhanced fuel efficiency, as the engine can run more smoothly and with less strain. Additionally, the sensor’s reliable performance helps increase the overall reliability of the truck, reducing the likelihood of unexpected breakdowns and maintenance issues 2.

Installation and Integration

Installing the Cummins 5260246 Pressure Sensor involves connecting it to the appropriate pressure points within the engine management system. It is important to follow manufacturer guidelines to ensure proper integration. This may include securing the sensor in place, connecting it to the ECU, and verifying that all connections are secure and free from contaminants. Proper installation is key to ensuring accurate pressure readings and optimal sensor performance 2.

Troubleshooting and Maintenance

Common issues with the Cummins 5260246 Pressure Sensor may include inaccurate readings or sensor failure. Troubleshooting typically involves checking the sensor’s connections, ensuring it is properly secured, and verifying that there are no obstructions or contaminants affecting its operation. Regular maintenance, such as cleaning the sensor and inspecting its connections, can help prevent issues and ensure longevity. If the sensor is found to be faulty, replacement may be necessary to maintain engine performance 2.

Performance Monitoring

Monitoring the performance of the Cummins 5260246 Pressure Sensor is crucial for maintaining engine efficiency and reliability. Mechanics and fleet operators can use diagnostic tools to check the sensor’s output and ensure it is within the expected range. Regular performance checks can help identify potential issues before they lead to more significant problems, allowing for timely maintenance or replacement as needed 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established itself as a trusted provider of high-quality components for the automotive industry. The company’s commitment to innovation and excellence is evident in its products, such as the 5260246 Pressure Sensor, which are designed to meet the demanding requirements of commercial truck operations 2.

Cummins Pressure Sensor 5260246 Compatibility

The Cummins Pressure Sensor part number 5260246 is designed to fit a variety of Cummins engines, ensuring compatibility across multiple models. This sensor is crucial for maintaining optimal engine performance by accurately measuring the pressure within the engine’s system 2.

ISB Series

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB/ISD4.5 CM2220 D108

The ISB series engines benefit from the 5260246 pressure sensor, which helps in monitoring and regulating the pressure levels, ensuring efficient operation and longevity of the engine 2.

ISBE Series

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series engines also utilize the 5260246 pressure sensor. This sensor is integral to the ISBE engines’ performance, providing essential data for maintaining the correct pressure levels within the engine’s system 2.

ISC Series

- ISC CM2150

- ISC CM850

The ISC series engines are equipped with the 5260246 pressure sensor, ensuring that the engine operates within the specified pressure parameters, which is vital for performance and efficiency 2.

ISF Series

- ISF3.8 CM2220 AN

The ISF3.8 CM2220 AN engine is compatible with the 5260246 pressure sensor, which is essential for maintaining the engine’s pressure levels and ensuring smooth operation 2.

ISL Series

- ISL9 CM2150 SN

The ISL9 CM2150 SN engine uses the 5260246 pressure sensor, which is crucial for monitoring and maintaining the correct pressure levels within the engine 2.

QSB Series

- QSB4.5 CM850 (CM2850)

- QSB5.9 CM850

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The QSB series engines, including the QSB4.5, QSB5.9, QSB6.7, QSB6.7 M, and QSB7, are all compatible with the 5260246 pressure sensor. This sensor is essential for these engines to maintain optimal pressure levels, ensuring efficient and reliable operation 2.

QSC and QSL Series

- QSC8.3 CM850 (CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM850 (CM2850)

The QSC and QSL series engines, such as the QSC8.3, QSL8.9, and QSL9, also utilize the 5260246 pressure sensor. This sensor is critical for these engines to monitor and maintain the correct pressure levels, ensuring optimal performance and efficiency 2.

Role of Part 5260246 Pressure Sensor in Engine Systems

The Part 5260246 Pressure Sensor is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency.

In the Campaign Kit, the Pressure Sensor provides real-time data on fuel and air pressure, allowing for precise adjustments to the engine’s operation. This ensures that the engine runs smoothly under a variety of conditions, enhancing both performance and reliability 2.

When integrated with the Camshaft, the Pressure Sensor aids in the synchronization of valve timing with fuel injection and ignition events. This coordination is essential for maximizing engine efficiency and power output 2.

In conjunction with the Connecting Rod and Piston assembly, the Pressure Sensor monitors cylinder pressure. This data is vital for assessing the health of the engine’s internal components, allowing for early detection of wear or malfunction 2.

The Cylinder Head benefits from the Pressure Sensor by receiving accurate pressure readings that help in fine-tuning the combustion process. This leads to improved fuel economy and reduced emissions 2.

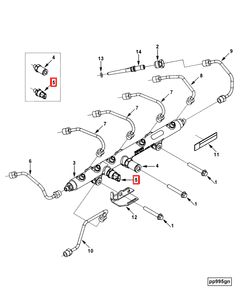

For the Fuel Injector Plumbing and Fuel Manifold, the Pressure Sensor ensures that the fuel is delivered at the correct pressure, which is crucial for maintaining the desired air-fuel ratio. This results in more efficient combustion and better overall engine performance 2.

The Injector relies on the Pressure Sensor to deliver fuel with precision. By monitoring the pressure within the fuel system, the sensor helps to maintain consistent fuel delivery, which is essential for smooth engine operation 2.

In the context of Injector Plumbing, the Pressure Sensor plays a role in preventing fuel leaks and ensuring that the fuel system operates within safe pressure limits. This is important for both the longevity of the engine and the safety of the vehicle 2.

When considering the Long Block, the Pressure Sensor provides valuable data that can be used to optimize the engine’s performance. By monitoring pressure within the engine, technicians can make informed adjustments to improve efficiency and power 2.

Lastly, for Performance Parts, the Pressure Sensor is often a key component in tuning and upgrading an engine. It provides the necessary data to tweak various systems for enhanced performance, whether for racing or everyday driving 2.

Overall, the Part 5260246 Pressure Sensor is a versatile component that enhances the functionality of multiple engine systems, contributing to a more responsive, efficient, and reliable engine 2.

Conclusion

The Cummins 5260246 Pressure Sensor is a critical component in the engine management system of commercial trucks. Its accurate pressure readings ensure optimal engine performance, fuel efficiency, and reliability. Proper installation, regular maintenance, and performance monitoring are essential to maximize the benefits of this sensor. With its robust design and compatibility across various Cummins engine models, the 5260246 Pressure Sensor is a valuable asset for maintaining the efficiency and longevity of commercial truck engines 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.