This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

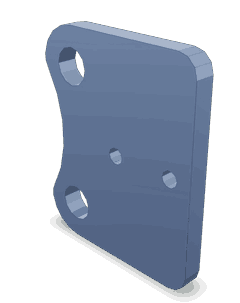

The Cummins 5266608 Sensor Bracket is a component designed for use in heavy-duty truck operations. Its primary role is to securely hold sensors in place, ensuring they function correctly within the truck’s engine system. This bracket is integral to maintaining the accuracy and reliability of sensor readings, which are vital for the efficient operation of the vehicle 1.

Purpose and Functionality

This Cummins part plays a role in the operation of a truck by providing a stable mounting point for sensors. These sensors monitor various engine parameters such as temperature, pressure, and emissions. The bracket’s design allows for precise sensor placement, which is crucial for accurate data collection. It integrates seamlessly with the truck’s engine management system, contributing to overall vehicle performance and efficiency 2.

Key Features

The design and construction of the 5266608 Sensor Bracket include several notable features. It is typically made from durable materials such as high-grade steel or aluminum, ensuring longevity and resistance to harsh operating conditions. The bracket offers versatile mounting options, allowing it to be securely attached to different parts of the engine. Additionally, it may include features like vibration damping elements to enhance sensor stability and accuracy 3.

Benefits

The advantages provided by this Cummins part include improved sensor stability, which leads to more accurate readings and better engine performance. Its design facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, the bracket contributes to the overall reliability of the engine system by ensuring sensors are properly positioned and protected 4.

Installation Process

Proper installation of the 5266608 Sensor Bracket involves several steps. First, identify the correct location on the engine for sensor placement. Next, use the appropriate tools to securely attach the bracket to the engine. Ensure that the sensor is properly aligned within the bracket and that all connections are tight and secure. Finally, verify that the sensor is functioning correctly by testing its readings.

Maintenance and Troubleshooting

To maintain the 5266608 Sensor Bracket, regular inspections should be conducted to ensure it remains securely attached and free from damage. Common issues may include loose connections or sensor misalignment, which can be addressed by re-securing the bracket or adjusting the sensor position. Troubleshooting procedures should involve checking for proper sensor readings and ensuring the bracket is not obstructed or damaged.

Safety Considerations

When installing or maintaining the 5266608 Sensor Bracket, it is important to observe safety guidelines. Ensure the engine is turned off and cooled down before beginning any work. Use appropriate personal protective equipment (PPE) such as gloves and safety glasses. Follow all manufacturer instructions and safety protocols to prevent injury to personnel and damage to equipment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. Their product range includes a variety of parts and systems designed to enhance the efficiency and durability of heavy-duty trucks.

Compatibility

The Cummins Sensor Bracket part number 5266608 is designed to fit seamlessly with a range of Cummins engines, ensuring precise alignment and secure mounting of sensors. This bracket is engineered to maintain the integrity and performance of the engine by providing a stable platform for critical sensors.

QSM11 Engines

The Cummins Sensor Bracket 5266608 is compatible with the QSM11 engine series. This bracket ensures that sensors are properly positioned, which is crucial for maintaining optimal engine performance and efficiency. The design of the bracket allows for easy installation and adjustment, making it a reliable component for technicians and mechanics.

CM570 Engines

Similarly, the Cummins Sensor Bracket 5266608 is also suitable for the CM570 engine series. This bracket’s robust construction and precise fit are essential for the accurate placement of sensors, which is vital for the engine’s diagnostic and operational systems. The bracket’s design ensures that sensors remain securely in place, even under the most demanding conditions.

Grouping of Compatible Engines

The Cummins Sensor Bracket 5266608 is engineered to fit multiple engine models, including but not limited to, the QSM11 and CM570 series. Its universal design allows it to be used across various engine types, providing a versatile solution for engine maintenance and repair. This compatibility ensures that technicians can rely on a single part for multiple engine applications, simplifying inventory management and reducing downtime.

Role of Part 5266608 Sensor Bracket in Engine Systems

The 5266608 Sensor Bracket is an integral component in the assembly and functionality of various engine systems. Its primary role is to securely mount sensors within the engine compartment, ensuring accurate and reliable data collection.

Integration with Engine Instrumentation

When installing engine instruments, the 5266608 Sensor Bracket provides a stable platform for sensors such as temperature, pressure, and oxygen sensors. This stability is essential for the sensors to function correctly, as any movement or instability can lead to inaccurate readings. The bracket ensures that sensors are positioned optimally to interact with engine components, facilitating precise data acquisition that is vital for engine performance monitoring and diagnostics.

Panel and Product Installation

During the installation of engine panels, the 5266608 Sensor Bracket plays a significant role in maintaining the structural integrity of the sensor setup. It is often attached to the panel, providing a fixed point for sensor attachment. This setup simplifies the product installation process, as technicians can rely on the bracket to hold sensors in place while other components are being installed or adjusted. The bracket’s design allows for easy access to sensors for maintenance or replacement, enhancing the overall efficiency of the installation process.

Package and Sensor Protection

In the context of packaging engine components, the 5266608 Sensor Bracket serves as a protective measure for sensors during transportation and storage. By securely holding sensors in place, it prevents them from shifting or becoming damaged, which could otherwise lead to malfunctions once installed. This protection is particularly important for delicate sensors that are susceptible to physical damage.

Enhanced Data Accuracy

The accurate placement of sensors facilitated by the 5266608 Sensor Bracket directly contributes to the reliability of engine data. Sensors that are properly mounted can provide consistent and precise measurements, which are essential for engine management systems to make informed adjustments. This, in turn, enhances engine efficiency, performance, and longevity.

Conclusion

The 5266608 Sensor Bracket is a key component in the successful integration and operation of sensors within engine systems. Its role in securing sensors, simplifying installation processes, and protecting sensors during handling underscores its importance in maintaining engine health and performance.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.