This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5284282 Sensor Bracket is a component designed for use in commercial trucks. Its primary role is to facilitate the mounting and stabilization of sensors within the truck’s engine system. This bracket ensures that sensors are securely positioned, which is vital for the accurate collection of data and the overall performance of the engine 1.

Purpose and Function

The Cummins 5284282 Sensor Bracket serves to support the mounting and stabilization of sensors in the truck’s engine system. By securely holding sensors in place, it allows for precise data collection, which is crucial for the engine’s operation. The bracket’s design ensures that sensors remain in the correct position, even under the dynamic conditions experienced by commercial trucks 2.

Key Features

This Cummins part is characterized by its robust design and the materials used in its construction. It is made from high-quality materials that offer durability and resistance to the harsh conditions found in commercial truck environments. The bracket’s design includes features that enhance its performance and longevity, such as corrosion-resistant coatings and precise engineering to ensure a secure fit for sensors.

Benefits

The use of the Cummins 5284282 Sensor Bracket provides several benefits. It contributes to improved sensor accuracy by ensuring that sensors are correctly positioned and secured. This leads to more reliable data collection, which is essential for the engine’s performance and reliability. Additionally, the bracket’s durable construction enhances the longevity of the sensors it supports, contributing to the overall efficiency and reliability of the truck’s engine system.

Installation and Compatibility

Proper installation of the Cummins 5284282 Sensor Bracket is important to ensure it functions as intended. Installation guidelines should be followed to secure the bracket correctly and ensure sensors are properly mounted. The bracket is designed to be compatible with various Cummins engine models, ensuring it can be used across a range of commercial truck applications.

Maintenance and Troubleshooting

To maintain the Cummins 5284282 Sensor Bracket and ensure optimal performance, regular inspections should be conducted to check for any signs of wear or damage. Common issues may include sensor misalignment or bracket corrosion, which can be addressed through readjustment or replacement as necessary. Proper maintenance of the bracket contributes to the longevity and accuracy of the sensors it supports.

Role in Engine Management

The Cummins 5284282 Sensor Bracket plays a role in the engine management system by ensuring sensors are correctly positioned and secured. This leads to accurate data collection, which is fundamental for the engine’s operation. Accurate sensor data allows the engine management system to make precise adjustments, enhancing performance and reliability.

Impact on Fuel Efficiency

Proper sensor placement, supported by the Cummins 5284282 Sensor Bracket, can influence fuel efficiency. By ensuring sensors are correctly positioned, the bracket helps the engine operate within optimal parameters. This can lead to more efficient fuel consumption, as the engine management system relies on accurate sensor data to make adjustments that improve fuel economy.

Safety Considerations

When installing and maintaining the Cummins 5284282 Sensor Bracket, safety considerations should be taken into account. Correct installation is important to prevent sensor malfunction, which could lead to inaccurate data collection and potentially affect the engine’s performance. Following safety guidelines and conducting regular maintenance checks can help ensure the bracket and the sensors it supports operate safely and effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a key player in the commercial truck industry. The company’s commitment to developing reliable and efficient engine components, like the Cummins 5284282 Sensor Bracket, underscores its dedication to enhancing the performance and reliability of commercial vehicles.

Role of 5284282 Sensor Bracket in Engine Systems

The 5284282 Sensor Bracket is an integral component in the mounting and stabilization of various sensors within engine systems, particularly those associated with aftertreatment devices. This bracket ensures that sensors are securely positioned to accurately monitor and regulate the performance of aftertreatment systems.

In the context of an aftertreatment device, the Sensor Bracket facilitates the precise placement of sensors that measure exhaust gas temperatures, pressures, and emissions levels. These sensors provide essential data to the engine control unit (ECU), allowing for real-time adjustments to fuel injection, air-fuel ratio, and other critical parameters to optimize engine performance and reduce emissions.

Additionally, the Sensor Bracket supports sensors that monitor the efficiency of catalytic converters and diesel particulate filters (DPFs). By maintaining the sensors in optimal positions, the bracket helps ensure that these aftertreatment components operate within specified parameters, enhancing overall system reliability and effectiveness.

Furthermore, the bracket plays a role in the durability and longevity of the sensors by protecting them from vibrations and physical stresses that occur during engine operation. This protection is vital for maintaining the accuracy and consistency of sensor readings over time.

Conclusion

In summary, the Cummins 5284282 Sensor Bracket is a key element in the integration and functionality of sensors within engine systems, particularly those related to aftertreatment processes. Its role in securing and stabilizing sensors contributes to the efficient operation and monitoring of engine performance and emissions control.

SPECIFICATIONS

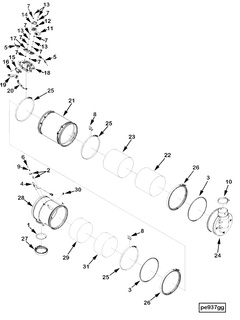

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.