This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

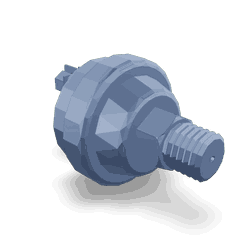

The Cummins 5287119 Blowby Flow Sensor is designed to monitor and manage the flow of blowby gases within heavy-duty truck engines. This part contributes to the engine’s operation by providing data that helps optimize performance and efficiency. Its significance lies in its ability to contribute to the overall health and efficiency of the engine, ensuring it operates within desired parameters.

Basic Concepts of Blowby Flow Sensors

A Blowby Flow Sensor measures the amount of gases that escape past the piston rings into the crankcase. These gases, known as blowby gases, consist of unburned fuel, combustion byproducts, and air. Monitoring these gases is important because it allows the engine management system to make adjustments that enhance performance and reduce emissions. The sensor operates by detecting the flow rate of these gases and sending this information to the engine control unit, which then makes necessary adjustments to the engine’s operation 1.

Purpose of the Cummins 5287119 Blowby Flow Sensor

The Cummins 5287119 Blowby Flow Sensor provides real-time data on blowby gas flow, allowing the engine management system to adjust various parameters, such as fuel injection timing and air-fuel ratio, to maintain engine efficiency and reduce emissions. By continuously monitoring and adjusting based on the sensor’s readings, the engine can operate more smoothly and with greater fuel efficiency 2.

Key Features

The Cummins 5287119 Blowby Flow Sensor is characterized by its robust design and construction, which includes high-quality materials that ensure durability and reliability. The sensor incorporates advanced technology that enhances its accuracy and responsiveness. Its design allows for easy integration into the engine management system, ensuring that it can provide precise and timely data.

Benefits of Using the Cummins 5287119 Blowby Flow Sensor

Utilizing the Cummins 5287119 Blowby Flow Sensor offers several advantages. It contributes to improved engine performance by ensuring that the engine operates within optimal parameters. This results in enhanced fuel efficiency, as the engine management system can make precise adjustments based on the sensor’s readings. Additionally, by reducing the amount of unburned fuel and harmful emissions released into the environment, the sensor plays a role in minimizing the truck’s environmental impact 3.

Installation and Integration

Proper installation of the Cummins 5287119 Blowby Flow Sensor involves several steps to ensure it functions correctly within the engine management system. It is important to follow manufacturer guidelines for installation, which may include preparing the sensor and ensuring it is securely mounted in the appropriate location. Once installed, the sensor should be calibrated and tested to confirm that it is providing accurate readings and that the engine management system is responding appropriately.

Troubleshooting and Maintenance

Common issues with the Cummins 5287119 Blowby Flow Sensor may include inaccurate readings or sensor failure. Diagnostic procedures should be followed to identify the root cause of any issues, which may involve checking the sensor’s connections, calibration, and overall condition. Regular maintenance, such as cleaning the sensor and ensuring it is free from obstructions, can help ensure its longevity and optimal performance.

Impact on Engine Performance and Emissions

The Cummins 5287119 Blowby Flow Sensor contributes to overall engine performance and emission control by providing accurate data on blowby gas flow. This allows the engine management system to make adjustments that enhance efficiency and reduce emissions. Real-world data and case studies have shown that trucks equipped with this sensor experience improved fuel efficiency and reduced emissions, demonstrating the sensor’s effectiveness in enhancing engine performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company is committed to developing advanced technologies that enhance the performance, efficiency, and reliability of its products, including the Cummins 5287119 Blowby Flow Sensor.

Compatibility with Cummins Engines

The Blowby Flow Sensor 5287119, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This sensor plays a role in monitoring and managing blowby gases, which are the byproducts of the combustion process that escape past the piston rings. Ensuring the proper functioning of this sensor is vital for maintaining engine efficiency and longevity.

ISL9 CM2150

The ISL9 CM2150 engine is a high-performance, heavy-duty diesel engine known for its robust design and reliability. The Blowby Flow Sensor 5287119 is specifically engineered to fit this engine model, providing accurate readings of blowby gases. This compatibility ensures that the engine operates within optimal parameters, enhancing performance and reducing the risk of engine damage.

SN, L8.9

The SN, L8.9 engine is another variant where the Blowby Flow Sensor 5287119 is applicable. This engine is part of the Cummins lineup that is widely used in various industrial applications. The sensor’s design allows it to be easily integrated into the engine’s blowby management system, ensuring that the engine’s performance is maintained at peak levels. The precise fit and function of this sensor are important for the efficient operation of the SN, L8.9 engine.

Grouping of Engines

The Blowby Flow Sensor 5287119 is compatible with both the ISL9 CM2150 and the SN, L8.9 engines, making it a versatile component for Cummins engine users. This compatibility is due to the sensor’s design, which adheres to Cummins’ engineering standards, ensuring a perfect fit and reliable performance across these engine models. The sensor’s ability to integrate smoothly with these engines highlights Cummins’ commitment to providing high-quality, compatible parts for their engine lineup.

Role of the 5287119 Blowby Flow Sensor in Engine Systems

The 5287119 Blowby Flow Sensor is an integral component in modern engine systems, working in conjunction with other vital parts to ensure optimal engine performance and efficiency.

Integration with the Sensor System

The Blowby Flow Sensor is designed to monitor the flow of blowby gases—unburned fuel, air, and combustion byproducts—that escape past the piston rings into the crankcase. This sensor provides real-time data to the Engine Control Unit (ECU), allowing for precise adjustments to fuel injection, ignition timing, and other parameters.

Interaction with the Oil Pressure System

Effective management of blowby gases is essential for maintaining proper oil pressure within the engine. Excessive blowby can lead to contamination of the oil, reducing its lubricating properties and potentially causing increased wear on engine components.

The Blowby Flow Sensor helps mitigate this by ensuring that the Positive Crankcase Ventilation (PCV) system operates efficiently. The PCV system routes blowby gases back into the intake manifold, where they are re-burned. This not only reduces emissions but also helps maintain a stable oil pressure environment.

Conclusion

In summary, the Cummins 5287119 Blowby Flow Sensor plays a significant role in enhancing engine performance by ensuring that blowby gases are managed effectively, thereby supporting the sensor and oil pressure systems in maintaining optimal engine conditions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.