This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5287968 Pressure Sensor is designed to monitor and report pressure levels within commercial truck systems. It ensures accurate pressure readings, contributing to the efficient and safe operation of the vehicle. This sensor is crucial for maintaining optimal performance by ensuring pressure levels are within the desired range 1.

Basic Concepts of Pressure Sensors

Pressure sensors measure the force exerted by a fluid per unit area within a system. They convert physical pressure into an electrical signal, which is interpreted by the vehicle’s electronic control unit (ECU). In automotive systems, these sensors are used in fuel systems, brake systems, and engine management systems to monitor and regulate pressure levels for optimal performance and safety 2.

Role of the 5287968 Pressure Sensor in Truck Operation

The Cummins 5287968 Pressure Sensor monitors pressure within the system it is installed in, providing real-time data to the ECU. This data allows the ECU to make adjustments to ensure the system operates within safe and efficient parameters. The sensor is integral to maintaining the performance and reliability of the truck’s systems 3.

Key Features

The Cummins 5287968 Pressure Sensor is characterized by its robust design and construction, featuring high-quality materials for durability and accuracy. It includes advanced technological aspects such as precise calibration and the ability to operate under a wide range of conditions, making it suitable for commercial truck operations 4.

Benefits of Using the 5287968 Pressure Sensor

Utilizing the Cummins 5287968 Pressure Sensor offers several advantages. It ensures systems operate at optimal pressure levels, enhances reliability by providing accurate and consistent data, and improves efficiency by preventing issues arising from incorrect pressure levels, thereby reducing the risk of system failures and extending component lifespan 5.

Installation and Integration

Proper installation and integration of the Cummins 5287968 Pressure Sensor require adherence to manufacturer guidelines. This includes correct positioning, secure attachment, and verification of compatibility with the truck’s ECU. All connections must be made according to specifications to ensure accurate readings and system compatibility 6.

Troubleshooting and Maintenance

To troubleshoot common issues with the Cummins 5287968 Pressure Sensor, verify correct installation and secure connections. Regular maintenance, such as cleaning the sensor and checking for wear or damage, can help ensure its longevity and optimal performance. Periodic calibration is also beneficial to maintain accuracy 7.

Data Interpretation and Usage

Interpreting the data provided by the Cummins 5287968 Pressure Sensor is vital for truck diagnostics. This data indicates whether the system is operating within the desired pressure range and helps identify potential issues before they become critical. Analyzing this data allows technicians to make informed decisions to enhance truck performance and safety 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations 9.

Pressure Sensor 5287968 in Cummins Engines

The Pressure Sensor 5287968, manufactured by Cummins, is a critical component in ensuring the optimal performance and efficiency of several Cummins engine models. This sensor monitors and regulates pressure within the engine’s systems, providing essential data for maintaining the engine’s operational integrity 10.

QSB3.3 CM2250 EC Engines

In the QSB3.3 CM2250 EC engines, the Pressure Sensor 5287968 is integral to the engine’s management system. It provides precise pressure readings that are vital for the engine’s control unit. This sensor’s placement and integration are meticulously engineered to withstand harsh conditions within the engine compartment, providing reliable data for efficient engine operation 11.

Grouping of Engines

The Pressure Sensor 5287968 is compatible with a range of Cummins engines, including the QSB3.3 CM2250 EC. Its design and functionality make it suitable for various engine models where pressure monitoring is crucial. The sensor’s compatibility across different engine types underscores its versatility and importance in maintaining engine performance and reliability 12.

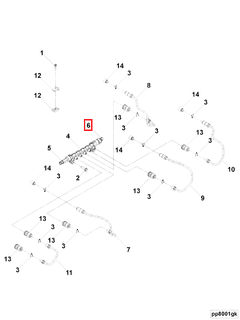

Role of Part 5287968 Pressure Sensor in Engine Systems

The integration of part 5287968, a pressure sensor, into engine systems is fundamental for maintaining optimal performance and efficiency. This sensor is strategically positioned to monitor and report pressure variations within key components.

Interaction with the Cylinder Head

The cylinder head is a vital component of the engine, housing the valves and injectors. The pressure sensor, when installed in this area, provides real-time data on the pressure within the combustion chamber. This information is essential for the engine control unit (ECU) to make precise adjustments to the air-fuel mixture, ignition timing, and valve timing. Consequently, this leads to improved combustion efficiency and reduced emissions 13.

Integration with the Fuel Manifold

In the fuel manifold, the pressure sensor plays a significant role in regulating fuel delivery. By monitoring the pressure of the fuel as it enters the manifold, the sensor ensures that the correct amount of fuel is delivered to each cylinder. This precise control is vital for maintaining the desired air-fuel ratio, which is critical for engine performance and fuel economy. The data from the sensor allows the ECU to make necessary adjustments to the fuel injectors, ensuring consistent and efficient fuel delivery across varying engine loads and speeds 14.

Conclusion

The Cummins 5287968 Pressure Sensor is an integral component in modern engine systems, enhancing performance, efficiency, and emissions control through its interaction with the cylinder head and fuel manifold. Its robust design, precise calibration, and compatibility with various engine models make it a crucial part of maintaining optimal engine performance and reliability.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Halderman, J.D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Department of Energy (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2150 B108. Bulletin Number 4326162.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2150 B108. Bulletin Number 4326162.

↩ -

Halderman, J.D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Department of Energy (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2150 B108. Bulletin Number 4326162.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2150 B108. Bulletin Number 4326162.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2150 B108. Bulletin Number 4326162.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Halderman, J.D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.