This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5319506 Pressure Sensor is designed to monitor and report pressure levels within a commercial truck’s systems, ensuring accurate readings that contribute to efficient and safe vehicle operation. This sensor is integral to maintaining optimal performance and ensuring the longevity of the truck’s components.

Basic Concepts of Pressure Sensors

Pressure sensors measure the force exerted by a fluid on a surface, converting this physical pressure into an electrical signal. In automotive applications, these sensors are used in various systems, including engine management, braking, and transmission, to ensure operation within designed parameters 1.

Role of the 5319506 Pressure Sensor in Truck Operation

The Cummins 5319506 Pressure Sensor is integrated into the truck’s electronic control unit (ECU), providing real-time data for adjusting engine and system operations. This data is essential for maintaining correct pressure levels, optimizing engine performance, and enhancing fuel efficiency 2.

Key Features of the 5319506 Pressure Sensor

This Cummins part is characterized by its robust design and high-quality materials, ensuring durability and reliability. It features advanced technological specifications for accurate and consistent pressure readings under various operating conditions. The sensor’s design also ensures it can withstand the harsh environments typical in commercial truck operations 3.

Benefits of Using the 5319506 Pressure Sensor

Using this Pressure Sensor contributes to improved engine performance by ensuring operation within the optimal pressure range, leading to enhanced fuel efficiency. It also aids in overall truck maintenance and safety by providing data that can help identify potential issues before they become serious problems 4.

Installation and Integration

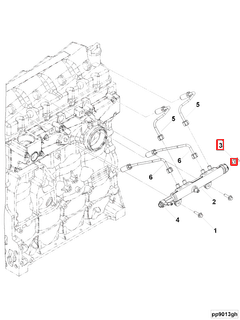

Proper installation and integration of the 5319506 Pressure Sensor are crucial for optimal performance. This involves connecting the sensor to the appropriate system and ensuring it is correctly interfaced with the truck’s ECU. Following manufacturer guidelines is important to maximize its effectiveness and longevity 5.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are essential for the longevity and consistent performance of the 5319506 Pressure Sensor. This includes checking for wear or damage, ensuring correct connections, and addressing any issues that arise. Regular maintenance can help identify potential problems early, allowing for timely repairs or replacements 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader known for its innovation and quality in the automotive components industry. The company’s products, including engines, filtration, and emissions technologies, are renowned for their reliability and performance. Cummins is committed to providing solutions that help customers reduce their environmental impact while maintaining high levels of performance and efficiency 7.

Compatibility of Cummins Pressure Sensor 5319506

The Cummins Pressure Sensor part number 5319506 is compatible with various Cummins engines, ensuring precise monitoring of pressure levels. It is engineered to integrate seamlessly with specified engines, providing reliable and accurate pressure readings essential for optimal engine performance. It is important to use the correct sensor for each engine type to maintain the integrity of the engine’s operational parameters 8.

Role of Part 5319506 Pressure Sensor in Engine Systems

The 5319506 Pressure Sensor is integral to modern engine systems, providing essential data that contributes to overall performance and efficiency.

Interaction with the Accumulator

In systems with an accumulator, the 5319506 Pressure Sensor monitors pressure levels, ensuring efficient fuel delivery system operation. The sensor’s readings help adjust fuel pressure to meet engine demands under varying conditions 9.

Camshaft and Valve Timing

The data from the 5319506 Pressure Sensor is used with the camshaft to fine-tune valve timing. Accurate pressure readings allow the engine control unit (ECU) to make real-time adjustments, enhancing combustion efficiency and reducing emissions 10.

Engine Head and Cylinder Pressure

Within the engine head, the 5319506 Pressure Sensor monitors cylinder pressure, particularly important during the combustion process. Precise pressure measurements help optimize the air-fuel mixture, assisting the ECU in making necessary adjustments to fuel injection timing and quantity 11.

Fuel Injector Performance

The 5319506 Pressure Sensor is closely linked to fuel injector performance. By providing real-time pressure data, the sensor enables the ECU to control the fuel injection process more accurately, resulting in better atomization of the fuel and more complete combustion 12.

Conclusion

The 5319506 Pressure Sensor is a key component in ensuring that various engine systems operate in harmony. Its precise pressure readings allow for real-time adjustments that enhance engine performance, efficiency, and longevity.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

John Dixon. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Sean Bennett. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Haoran Hu, Rudy Smaling, Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Cummins Inc. Corporate website. Accessed March 2024.

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

John Dixon. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Sean Bennett. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Haoran Hu, Rudy Smaling, Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.