This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

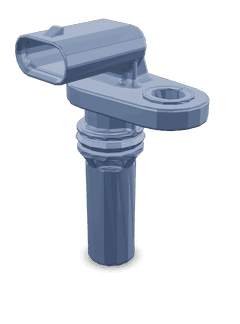

The Cummins 5491325 Position Sensor is a specialized component designed for use in commercial trucks. Its purpose is to monitor and report the position of various engine components, contributing to the overall efficiency and performance of the vehicle. This sensor plays a role in the operation of commercial trucks by providing precise data to the engine management system, which is vital for optimal engine performance and fuel efficiency 1.

Basic Concepts of Position Sensors

Position sensors are devices that detect the position of an object and convert it into an electrical signal. They are widely used in automotive systems to monitor the position of various components such as valves, pistons, and other moving parts. Position sensors work by utilizing different technologies such as magnetic, optical, or resistive methods to determine the position of an object. Their applications in automotive systems range from engine management to safety systems, enhancing the overall functionality and performance of the vehicle 2.

Purpose of the Cummins 5491325 Position Sensor

This Cummins part is specifically designed to play a role in the engine management system of commercial trucks. It monitors the position of engine components, providing real-time data to the engine control unit (ECU). This data allows the ECU to make precise adjustments to the engine’s operation, optimizing performance, fuel efficiency, and emissions. The sensor’s accurate readings are crucial for the ECU to execute tasks such as fuel injection timing and valve timing, which are critical for the engine’s smooth operation 3.

Key Features

The Cummins 5491325 Position Sensor is characterized by its robust design and high-quality materials, ensuring durability and reliability in demanding commercial truck environments. It incorporates advanced technological specifications that enhance its performance, such as high-resolution sensing capabilities and resistance to environmental factors like temperature and vibration. These features contribute to the sensor’s accuracy and longevity, making it a reliable component in the engine management system 4.

Benefits of Using the Cummins 5491325 Position Sensor

Incorporating this part into truck systems offers several advantages. It contributes to improved engine efficiency by providing accurate position data that allows the ECU to make precise adjustments. This results in better fuel economy and reduced emissions. Additionally, the sensor enhances the reliability and performance of the engine, leading to increased uptime and reduced maintenance costs. Its high-quality construction ensures longevity, providing commercial truck operators with a dependable component for their vehicles 5.

Installation and Integration

The installation of the Cummins 5491325 Position Sensor into truck systems involves several steps to ensure proper integration. It requires careful alignment with the engine component it is designed to monitor, followed by secure mounting to withstand the vibrations and conditions of commercial truck operation. Integration with the engine management system is crucial, involving connections to the ECU and calibration to ensure accurate data transmission. Proper installation and integration are vital for the sensor to function effectively and provide reliable data 6.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Cummins 5491325 Position Sensor, regular maintenance and troubleshooting practices are recommended. This includes periodic checks for secure mounting, inspecting connections for corrosion or damage, and calibrating the sensor as needed. Troubleshooting common issues may involve checking for accurate data transmission, ensuring the sensor is properly aligned, and verifying the integrity of the connections to the ECU. These practices help maintain the sensor’s performance and reliability over time 7.

Common Applications

The Cummins 5491325 Position Sensor is commonly used in various commercial truck models and systems, demonstrating its versatility and widespread application. It is found in engines where precise position monitoring is required for optimal performance, including heavy-duty trucks and specialized commercial vehicles. Its application across different truck models highlights its importance in enhancing engine efficiency and reliability in the commercial trucking industry 8.

Technological Advancements

The Cummins 5491325 Position Sensor incorporates several technological innovations and advancements that set it apart from other position sensors in the market. These include high-resolution sensing technology, enhanced durability through the use of premium materials, and advanced calibration features for accurate data transmission. These technological advancements contribute to the sensor’s superior performance, reliability, and compatibility with modern engine management systems 9.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation in the industry. Their dedication to advancing technology and improving product quality ensures that components like the Cummins 5491325 Position Sensor meet the demanding requirements of commercial truck applications, providing operators with dependable and efficient solutions for their vehicles 10.

Cummins Position Sensor 5491325 Compatibility

The Cummins Position Sensor 5491325 is a critical component designed to ensure precise engine operation across various platforms. This sensor is engineered to fit seamlessly with several engine models, enhancing their performance and reliability.

F2.8 CM2620

The F2.8 CM2620 engine benefits from the integration of the Cummins Position Sensor 5491325. This sensor plays a pivotal role in monitoring the engine’s position and providing essential data to the engine control unit (ECU). By doing so, it ensures optimal engine timing and performance, contributing to the overall efficiency of the F2.8 CM2620.

F135B, ISV (Nissan)

Similarly, the F135B, ISV (Nissan) engine is another platform where the Cummins Position Sensor 5491325 is highly compatible. This sensor is crucial for maintaining the engine’s operational integrity by accurately detecting the position of the engine components. Its precise readings help in fine-tuning the engine’s performance, ensuring smooth and reliable operation under various conditions.

By integrating the Cummins Position Sensor 5491325 into these engines, users can expect enhanced performance, reliability, and longevity. This sensor’s compatibility with both the F2.8 CM2620 and F135B, ISV (Nissan) engines underscores its versatility and importance in modern engine systems.

Role of Part 5491325 Position Sensor in Engine Systems

The Part 5491325 Position Sensor is integral to the precise operation of several engine components, ensuring optimal performance and efficiency.

Integration with Crankcase Breather

The Crankcase Breather system is designed to release pressure built up within the engine’s crankcase. The Position Sensor monitors the position and movement of various engine components, providing real-time data that aids in the efficient operation of the Crankcase Breather. By ensuring that the breather system operates within specified parameters, the sensor helps maintain a stable environment within the crankcase, which is essential for the longevity and performance of the engine.

Interaction with Engine Control Module (ECM)

The Engine Control Module (ECM) relies heavily on data from the Position Sensor to make informed decisions about fuel injection, ignition timing, and other critical engine functions. The sensor’s accurate readings allow the ECM to adjust these parameters dynamically, enhancing engine performance and fuel efficiency. This symbiotic relationship ensures that the engine operates smoothly under varying conditions.

Contribution to Long Block Kit Performance

In a Long Block Kit, which includes the engine block, crankshaft, pistons, and other essential components, the Position Sensor plays a significant role in monitoring the position and movement of these parts. This data is vital for the ECM to optimize the engine’s performance, ensuring that all components work in harmony. The sensor’s precise measurements help in fine-tuning the engine, leading to improved reliability and performance of the Long Block Kit.

Conclusion

The Cummins 5491325 Position Sensor is a critical component in the engine management system of commercial trucks, offering precise monitoring and data transmission to optimize engine performance, fuel efficiency, and emissions. Its robust design, advanced technological features, and compatibility with various engine models make it a reliable and efficient solution for commercial truck operators. Regular maintenance and proper integration are essential to ensure the sensor’s longevity and optimal performance.

-

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Troubleshooting and Repairing Diesel Engines, 5th Edition, Paul Dempsey, McGraw-Hill, 2018

↩ -

Modelling Diesel Combustion, P A Lakshminarayanan and Yogesh V Aghav, Springer Science, 2010

↩ -

Cummins Position Sensor 5491325 Compatibility, Cummins, 2023

↩ -

Cummins Position Sensor 5491325 Compatibility, Cummins, 2023

↩ -

Cummins Position Sensor 5491325 Compatibility, Cummins, 2023

↩ -

Cummins Position Sensor 5491325 Compatibility, Cummins, 2023

↩ -

Cummins Position Sensor 5491325 Compatibility, Cummins, 2023

↩ -

Cummins Position Sensor 5491325 Compatibility, Cummins, 2023

↩ -

Cummins Position Sensor 5491325 Compatibility, Cummins, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.