This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

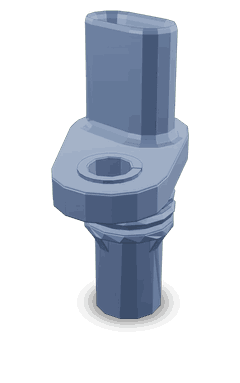

Introduction to Cummins 5491326NX Position Sensor

Cummins Inc. is a leader in the commercial truck industry, known for its innovative and reliable engines. Among its advanced components is the 5491326NX Position Sensor, a vital part of modern engine management systems.

Basic Concepts of a Position Sensor

A position sensor detects the position of an object and converts it into an electrical signal. These sensors are crucial in automotive applications, providing essential data to the engine control unit (ECU) for optimal performance. Types of position sensors include potentiometers, Hall effect sensors, and inductive sensors, each serving specific functions within the engine system 1.

Function and Importance of the Cummins 5491326NX Position Sensor

The Cummins 5491326NX Position Sensor monitors the position of critical engine components, providing real-time data to the ECU. This ensures precise control over engine operations, maintaining performance, fuel efficiency, and emissions compliance. Accurate position sensing is essential for engine reliability and longevity 2.

How the Cummins 5491326NX Position Sensor Works

This Cummins part operates by detecting the position of moving components like camshafts or crankshafts and converting this motion into an electrical signal. The signal is transmitted to the ECU, which uses the data to adjust fuel injection, ignition timing, and other parameters. The sensor is designed for high accuracy and durability under harsh commercial trucking conditions 3.

Troubleshooting Common Issues with the Cummins 5491326NX Position Sensor

Early identification of issues with this part can prevent significant engine problems. Common symptoms of a failing sensor include erratic engine performance, difficulty starting, and illuminated check engine lights. Troubleshooting steps include:

- Verifying the sensor’s electrical connections.

- Using a multimeter to check for proper voltage and signal output.

- Inspecting the sensor for physical damage or wear. Tools required for diagnosis include a digital multimeter, oscilloscope, and appropriate scan tools to interface with the ECU.

Maintenance and Care for the Cummins 5491326NX Position Sensor

Regular maintenance of the 5491326NX Position Sensor is crucial for its longevity and performance. Best practices include periodic inspection for wear or corrosion, cleaning the sensor and its connections to prevent buildup, and following the manufacturer’s guidelines for replacement intervals. Typically, position sensors are designed to last the lifetime of the engine, but environmental factors and usage can influence their durability.

Cummins: A Leader in Commercial Truck Technology

Cummins Inc. has a history of pioneering advancements in the commercial truck industry. Founded in 1919, the company has grown to become a global leader, renowned for its commitment to innovation, quality, and customer satisfaction. Cummins’ extensive product line, which includes engines, powertrains, and aftermarket parts, has significantly impacted the industry, setting new standards for performance and reliability.

Expert Insights and Best Practices

Experienced engineers and mechanics emphasize the importance of integrating position sensors into routine maintenance schedules. Regular checks and timely replacements can prevent unexpected failures and ensure optimal engine performance. Case studies have shown that proactive sensor maintenance can lead to improved fuel efficiency, reduced emissions, and extended engine life.

Conclusion

The Cummins 5491326NX Position Sensor is a critical component in the engine management system of commercial trucks. Understanding its function, importance, and maintenance requirements is essential for ensuring engine performance and longevity. By following best practices and leveraging expert insights, mechanics and engineers can maximize the efficiency and reliability of their fleets. Proper maintenance and timely troubleshooting of position sensors are paramount in achieving optimal engine performance and longevity.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.