5491994

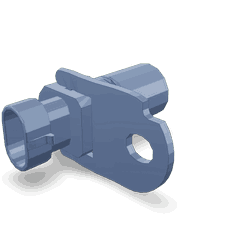

Position Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5491994 Position Sensor is a component designed to monitor and report the position of various parts within commercial trucks. Its purpose is to provide accurate data that contributes to the efficient operation of the vehicle. By integrating with the truck’s electronic control systems, this sensor plays a role in optimizing performance and ensuring reliable operation 1.

Basic Concepts of Position Sensors

Position sensors are devices that detect the location or position of mechanical components. They operate by converting physical movement into an electrical signal, which can then be interpreted by the vehicle’s control systems. These sensors are widely used in automotive applications to enhance system performance, improve safety, and increase efficiency. They are integral to various systems, including engine management, transmission control, and braking systems 2.

Role of the 5491994 Position Sensor in Truck Operation

This Cummins part performs specific functions within a truck’s system. It monitors the position of components such as valves or actuators, providing real-time data to the engine control unit (ECU). This information allows the ECU to make precise adjustments to the engine’s operation, ensuring optimal performance under varying conditions. The sensor’s interaction with other components contributes to the overall efficiency and reliability of the truck 3.

Key Features

The 5491994 is designed with several features that enhance its performance and reliability. Its construction includes high-quality materials that ensure durability in the demanding environment of a commercial truck. The sensor incorporates advanced technology to provide accurate and consistent readings, which is vital for the precise operation of the truck’s systems. Additionally, its design allows for easy integration into existing systems, facilitating straightforward installation and maintenance 4.

Benefits

The advantages provided by this part include improved accuracy in position detection, which leads to more precise control of the truck’s systems. This accuracy contributes to enhanced system efficiency, potentially leading to better fuel economy and reduced emissions. The sensor’s reliable performance also supports the overall longevity and dependability of the vehicle.

Troubleshooting and Maintenance

Common issues that may arise with this part include inaccurate readings or complete failure of the sensor. Diagnostic procedures involve checking the sensor’s output signal against expected values and inspecting the sensor and its connections for physical damage. Regular maintenance, such as cleaning the sensor and ensuring secure connections, can help prevent issues and ensure optimal performance. It is also important to follow the manufacturer’s guidelines for testing and replacement to maintain the sensor’s effectiveness.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial vehicle industry for producing high-quality, reliable components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications. Cummins is recognized for its commitment to innovation, efficiency, and sustainability in the power industry.

Cummins Position Sensor 5491994 in ISX CM570 and ISX CM871 Engines

The Cummins Position Sensor 5491994 is a component in the ISX CM570 and ISX CM871 engines, ensuring precise engine operation and performance. This sensor is integral to the engine’s electronic control system, providing data for the engine control module (ECM) to manage various functions.

ISX CM570 Engine

In the ISX CM570 engine, the position sensor 5491994 is strategically placed to monitor the rotational position of the crankshaft. This data is vital for the ECM to time the fuel injection and ignition events accurately, ensuring optimal engine performance and efficiency. The sensor’s placement and design are tailored to withstand the high temperatures and pressures within the engine, maintaining reliability over extended periods.

ISX CM871 Engine

Similarly, in the ISX CM871 engine, the position sensor 5491994 plays a role in the engine’s operation. It provides real-time feedback on the crankshaft’s position, which is crucial for the ECM to manage the engine’s timing and fuel delivery. The sensor’s precision and durability are key to the engine’s overall performance, helping to maintain consistent power output and fuel efficiency.

Common Features

Both engines utilize the position sensor 5491994 to enhance their operational capabilities. The sensor’s design ensures it can accurately detect the crankshaft’s position, even under varying engine loads and speeds. This accuracy is essential for the ECM to make timely adjustments to the engine’s timing and fuel injection, contributing to the engine’s overall efficiency and longevity.

The Cummins Position Sensor 5491994 is a testament to the brand’s commitment to quality and performance, providing reliable and precise data that is crucial for the smooth operation of the ISX CM570 and ISX CM871 engines.

Role of Part 5491994 Position Sensor in Engine Systems

The 5491994 Position Sensor is an integral component in the orchestration of various engine systems, ensuring precise and efficient operation. When integrated with the Engine Control Module (ECM), this sensor provides real-time data on the position of specific engine components, allowing the ECM to make informed adjustments to fuel injection, ignition timing, and other critical parameters.

In conjunction with the engine control systems, the position sensor enhances the overall performance and reliability of the engine. It facilitates smooth transitions between different operational states by continuously monitoring and reporting the exact position of moving parts. This information is vital for the ECM to execute commands that optimize fuel efficiency, reduce emissions, and enhance power output.

Moreover, the position sensor works in harmony with other sensors and actuators within the engine system to maintain a balanced and responsive engine performance. Its ability to provide accurate positional data ensures that the engine operates within its optimal range, thereby prolonging the lifespan of the engine components and improving the driving experience.

Conclusion

The Cummins 5491994 Position Sensor is a vital component in the efficient and reliable operation of commercial trucks and engines. Its role in providing accurate positional data to the engine control systems ensures optimal performance, enhanced efficiency, and improved reliability. Regular maintenance and adherence to manufacturer guidelines are essential to maintain the sensor’s effectiveness and contribute to the overall longevity of the vehicle.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.