This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

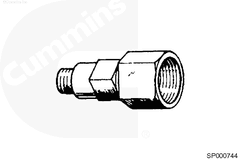

The Cummins 3162379 Service Tool is a specialized instrument designed for the maintenance and operation of commercial trucks. This tool is integral to ensuring the efficient and reliable performance of truck components, facilitating various service procedures that are vital for the upkeep of commercial vehicles 1.

Purpose and Functionality

This Cummins part plays a significant role in truck maintenance by aiding in specific service procedures. It is designed to interact with various truck components, ensuring they function correctly. This tool is particularly useful in diagnostic and repair processes, where precision and reliability are paramount. By facilitating these procedures, it helps maintain the overall health and performance of commercial trucks 2.

Key Features

The Cummins 3162379 Service Tool is characterized by its robust design and the high-quality materials used in its construction. These features contribute to its durability and effectiveness in demanding maintenance tasks. The tool’s design incorporates ergonomic considerations, making it easier to handle and use for extended periods. Additionally, it features precise engineering to ensure accurate and reliable performance in various service scenarios 3.

Benefits of Using the Cummins 3162379 Service Tool

Utilizing this part offers several advantages. It enhances the efficiency of maintenance tasks, reducing the time required for service procedures. This efficiency can lead to significant cost savings for fleet operators. Moreover, the tool’s design prioritizes user safety, minimizing the risk of injury during use. Its reliability and durability also contribute to long-term cost-effectiveness, making it a valuable asset for any commercial truck maintenance operation 4.

Operational Guidelines

To use the Cummins 3162379 Service Tool effectively, it is important to follow specific guidelines. Begin by ensuring the tool is properly set up according to the manufacturer’s instructions. When using the tool, adhere to the recommended procedures for each service scenario to achieve optimal results. Regular calibration and inspection of the tool are also recommended to maintain its accuracy and reliability 5.

Troubleshooting and Maintenance

Common issues with the Cummins 3162379 Service Tool may include calibration errors or wear and tear on certain components. Troubleshooting these issues typically involves recalibrating the tool or replacing worn parts. Regular maintenance, such as cleaning and inspecting for damage, is crucial to ensure the tool’s longevity and reliability. Following the manufacturer’s maintenance schedule will help prevent many common problems 6.

Safety Considerations

When using the Cummins 3162379 Service Tool, it is important to observe certain safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, handling the tool with care and following all operational instructions will help ensure a safe working environment 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to innovation and quality in the automotive and engine manufacturing industry. The company’s extensive product range includes engines for on-highway, off-highway, and stationary applications, demonstrating its versatility and expertise in the field 8.

Conclusion

The Cummins 3162379 Service Tool is an essential component in the maintenance and operation of commercial trucks. Its robust design, precise engineering, and ergonomic features make it a reliable and efficient tool for various service procedures. By adhering to operational guidelines, performing regular maintenance, and observing safety considerations, users can maximize the benefits of this Cummins part, ensuring the efficient and reliable performance of their commercial vehicles.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5504616) for engine F2.8 CM2620 F135B.

↩ -

Cummins Inc. (n.d.). Service Manual (5504616) for engine F2.8 CM2620 F135B.

↩ -

Cummins Inc. (n.d.). Service Manual (5504616) for engine F2.8 CM2620 F135B.

↩ -

Cummins Inc. (n.d.). Service Manual (5504616) for engine F2.8 CM2620 F135B.

↩ -

Cummins Inc. (n.d.). Service Manual (5504616) for engine F2.8 CM2620 F135B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.