This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

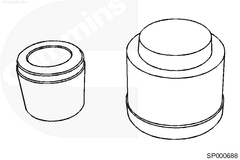

The Guide Oil Seal Driver 3162395 is a specialized tool manufactured by Cummins, a renowned entity in the automotive and heavy-duty truck sector. This part is engineered to aid in the installation and removal of oil seals within heavy-duty truck engines. Its significance lies in preserving the integrity and performance of truck engines by ensuring oil seals are correctly seated without incurring damage.

Function and Operation

This Cummins part facilitates the installation and removal of oil seals through a precise and controlled method, applying even pressure to seat the seal correctly within its housing. This mechanism is integral to maintaining the seal’s integrity, thereby ensuring its effectiveness in preventing oil leaks and contamination. Proper seal installation is crucial for the engine’s lubrication system, directly impacting overall engine performance and longevity 1.

Key Features

The Guide Oil Seal Driver 3162395 is designed with durability and precision at its core. Constructed from high-quality materials, it boasts a robust design capable of withstanding the demands of heavy-duty truck maintenance. Its features include an easy alignment mechanism and a design that allows for the application of force with minimal risk of seal damage during installation or removal 2.

Benefits

Utilizing the Guide Oil Seal Driver 3162395 enhances the efficiency of oil seal installation, reducing maintenance task duration. The tool’s design ensures a proper seal fit, leading to improved engine performance through optimal lubrication and prevention of oil leaks. Furthermore, its use can extend the longevity of oil seals by minimizing installation-related damage 3.

Installation Process

To employ the Guide Oil Seal Driver 3162395, ensure the engine compartment is clean and free from debris. Select the appropriate driver size for the oil seal. Align the driver correctly over the seal and apply steady pressure to drive it into its housing, ensuring even seating. Post-installation, inspect the seal for proper fit and function. Safety measures include wearing appropriate personal protective equipment (PPE) and ensuring the engine is cool before commencing work.

Maintenance and Troubleshooting

Maintaining the Guide Oil Seal Driver 3162395 involves keeping it clean and free from oil or grease buildup, which could impair its performance. Regular inspections for wear or damage are recommended, with replacement as necessary to maintain optimal performance. Common issues, such as difficulty in seal alignment or uneven seating, can often be addressed by re-aligning the driver or applying pressure more evenly.

Safety Considerations

When utilizing the Guide Oil Seal Driver 3162395, adhering to safety practices is paramount. Always wear appropriate PPE, including gloves and safety glasses, to safeguard against injury. Ensure the engine is off and cool prior to initiating any maintenance work. Adhere to the manufacturer’s instructions for use to avert damage to the tool or the oil seal. Additionally, be cognizant of your surroundings, ensuring the work area is secure and devoid of hazards.

Cummins Overview

Cummins Inc. stands as a global power leader, designing, manufacturing, and distributing engines, filtration, and power generation products. With a legacy exceeding a century, Cummins has garnered a reputation for quality, innovation, and reliability within the automotive and heavy-duty truck industry. The company’s product portfolio encompasses engines, powertrains, and related components, catering to a diverse range of industries and applications. Cummins’ dedication to excellence and customer satisfaction has solidified its position as a trusted name in the industry 4.

Conclusion

The Guide Oil Seal Driver 3162395 by Cummins is an indispensable tool for maintaining the integrity and performance of heavy-duty truck engines. Its precise design and robust construction facilitate efficient and safe installation and removal of oil seals, contributing to the longevity and optimal performance of engine lubrication systems. Adhering to safety practices and regular maintenance of this part ensures its continued effectiveness in heavy-duty truck maintenance tasks.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Reif, Konrad, ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.