This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

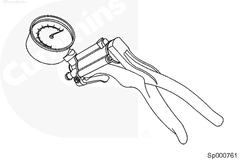

The Cummins 3162422 Service Tool is a specialized instrument designed for the maintenance and operation of commercial trucks equipped with Cummins engines. This tool is integral to ensuring the efficient and reliable performance of truck components, facilitating various service procedures that are vital for the upkeep of these vehicles 1.

Purpose and Functionality

This Cummins part plays a role in truck maintenance by assisting in specific service procedures. It is designed to interact with various components of Cummins engines, aiding in tasks such as fuel system maintenance, sensor calibration, and diagnostic checks. By ensuring the proper functioning of these components, the tool contributes to the overall reliability and performance of the truck 2.

Key Features

The Cummins 3162422 Service Tool is characterized by several primary features that enhance its performance and durability. Its design incorporates robust materials that withstand the rigors of frequent use in a commercial setting. Unique attributes such as ergonomic handles and precision-machined parts ensure that the tool is both effective and easy to use, reducing the likelihood of user error during maintenance tasks 3.

Benefits

Using the Cummins 3162422 Service Tool offers several advantages. It improves efficiency in maintenance tasks by providing a dedicated instrument for specific procedures, which can lead to reduced downtime for trucks. Additionally, it enhances safety for mechanics by offering a precise and controlled way to perform maintenance, minimizing the risk of injury. Fleet operators may also experience cost savings due to the tool’s ability to facilitate more accurate and efficient maintenance, potentially extending the lifespan of truck components 4.

Operational Guidelines

To use the Cummins 3162422 Service Tool effectively, follow these step-by-step instructions:

- Ensure the truck is safely parked and the engine is turned off.

- Connect the tool to the appropriate port on the Cummins engine.

- Follow the specific procedure for the maintenance task at hand, as outlined in the tool’s instruction manual.

- After completing the task, disconnect the tool and store it in a safe place.

Best practices for achieving optimal results include regularly reviewing the instruction manual for updates and ensuring that the tool is clean and in good condition before use 5.

Troubleshooting and Maintenance

Common issues with the Cummins 3162422 Service Tool may include connectivity problems or inaccurate readings. Troubleshooting steps involve checking the connections for secure fitment and ensuring the tool is clean and free from debris. Routine maintenance, such as cleaning and inspecting for wear, can prolong the tool’s lifespan and ensure consistent performance 6.

Safety Considerations

When using the Cummins 3162422 Service Tool, it is important to follow safety protocols to prevent accidents and injuries. This includes wearing appropriate personal protective equipment, ensuring the truck is securely parked before beginning any maintenance, and adhering to all safety guidelines provided in the tool’s instruction manual. Proper training on the use of the tool is also significant to ensure safe and effective operation 7.

Integration with Cummins Engines

The Cummins 3162422 Service Tool is designed to interact with various Cummins engine models, facilitating specific maintenance tasks. Its compatibility with these engines allows for precise diagnostics and maintenance procedures, ensuring that the engine components operate within specified parameters 8.

User Testimonials and Case Studies

Real-world examples and feedback from mechanics and fleet operators highlight the effectiveness of the Cummins 3162422 Service Tool. Case studies demonstrate its role in improving maintenance efficiency, enhancing safety during service procedures, and contributing to the overall reliability of commercial trucks 9.

Conclusion

The Cummins 3162422 Service Tool is a vital component in the maintenance and operation of commercial trucks equipped with Cummins engines. Its design, functionality, and integration with Cummins engines make it an indispensable tool for mechanics and fleet operators. By following operational guidelines, performing routine maintenance, and adhering to safety considerations, users can maximize the benefits of this Cummins part, ensuring the efficient and reliable performance of their vehicles.

-

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F3.8 CM2350 F132B. Bulletin Number 5467328.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F3.8 CM2350 F132B. Bulletin Number 5467328.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F3.8 CM2350 F132B. Bulletin Number 5467328.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.