Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 208119 Idler Shaft is a specialized component designed for commercial trucks, integral to the engine’s timing system. Its primary function is to maintain the alignment and tension of the timing belt or chain, ensuring synchronized operation of the engine’s valves and pistons. This synchronization is crucial for the engine’s efficient and reliable performance 1.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component that guides, tensions, or redirects a belt, chain, or cable in various systems. In truck engines, the idler shaft maintains the correct tension on the timing belt or chain, which is essential for the precise operation of engine components. By adjusting the belt or chain’s path, the idler shaft ensures accurate engine timing, contributing to overall engine performance 3.

Purpose of the Cummins 208119 Idler Shaft

This Cummins part is engineered to maintain the correct tension on the timing belt or chain, ensuring that the engine’s valves open and close at precise moments relative to the piston’s position. This is fundamental for the engine’s combustion process, affecting efficiency, power output, and longevity 1.

Key Features

The Cummins 208119 Idler Shaft is known for its robust design and high-quality materials, contributing to its durability and performance. It is designed to withstand high stresses and temperatures within an engine environment. Precision machining ensures accurate fitment and operation, while coatings or treatments enhance resistance to wear and corrosion 2.

Benefits

Incorporating the Cummins 208119 Idler Shaft into a truck’s engine offers advantages such as improved engine efficiency through optimal tension on the timing belt or chain. This reduces wear on other timing system components and enhances engine durability. Precise engine timing contributes to consistent performance and reliability 1.

Installation Considerations

Proper installation of the Cummins 208119 Idler Shaft is crucial. Following manufacturer guidelines ensures proper fitment and operation. This may involve using specific tools for alignment and tensioning the timing belt or chain. Ensuring the engine is at the correct position in its cycle before installation is also important 1.

Troubleshooting Common Issues

Common issues with the Cummins 208119 Idler Shaft include noise from the timing system, signs of wear on the timing belt or chain, or engine misfires due to incorrect timing. Troubleshooting may involve inspecting the idler shaft for wear or damage, checking the tension of the timing belt or chain, and ensuring proper alignment and installation. Addressing these issues promptly can prevent more significant engine problems 1.

Maintenance Tips

Regular maintenance of the Cummins 208119 Idler Shaft is essential for optimal performance and longevity. This includes periodic inspections for wear or damage, ensuring proper tension of the timing belt or chain, and lubricating the shaft as recommended by the manufacturer. Adhering to these practices helps prevent unexpected failures and extends the component’s service life 1.

Cummins Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is evident in its products, including the Cummins 208119 Idler Shaft, designed to meet the demanding requirements of commercial truck engines 2.

Role of Part 208119 Idler Shaft in Engine Systems

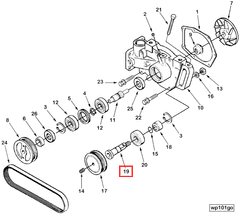

The idler shaft, specifically part 208119, is crucial for the efficient operation of various engine components. In the water pump and idler system assembly, this shaft ensures smooth rotation and proper tension of the belt that drives both the water pump and the idler pulley. It works in conjunction with the idler and water pump to maintain consistent belt tension, essential for the reliable operation of these components. The idler shaft provides a stable axis for the pulley to rotate, maintaining the correct alignment and tension of the drive belt. In the idler pump setup, the idler shaft transfers motion from the engine to the pump, ensuring the pump operates at the correct speed and efficiency. This is particularly important in systems where the water pump and idler are combined, as the idler shaft must manage the dynamics of both components to prevent slippage or excessive wear. The integration of the idler shaft in the water pump assembly is designed to enhance the durability and performance of the water pump. By supporting the idler pulley, it allows the water pump to function optimally under varying engine loads and speeds 3.

Conclusion

The Cummins 208119 Idler Shaft plays a significant role in maintaining the efficiency and reliability of commercial truck engines. Its design and functionality are crucial for the proper operation of the engine’s timing system, contributing to overall engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ ↩ ↩ ↩ ↩ ↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023.

↩ ↩ -

Fundamentals of Vehicle Dynamics and Modelling, Bruce P. Minaker, John Wiley Sons, 2019.

↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.