This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

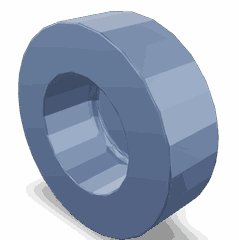

The Crankshaft Pulley Assembly, identified by part number 3008808, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its heavy-duty truck engines. This assembly is integral to the efficient operation of heavy-duty trucks, ensuring the smooth transfer of power from the engine to various auxiliary systems.

Basic Concepts

The Crankshaft Pulley Assembly operates on fundamental mechanical principles. It is a part of the engine’s drive system, responsible for transmitting rotational force from the crankshaft to other engine components. This transmission is achieved through a series of belts or chains connected to the pulley, which in turn drives accessories such as the alternator, water pump, and air conditioning compressor 1.

Purpose and Function

This Cummins part plays a significant role in the operation of a truck’s engine. It interfaces directly with the crankshaft, converting the engine’s linear piston motion into rotational force. This rotational force is then distributed to various engine components, ensuring they operate in sync with the engine’s rhythm. The assembly’s design allows for efficient power transmission with minimal energy loss, contributing to the overall performance and reliability of the engine 2.

Key Features

The Crankshaft Pulley Assembly is characterized by several key features that enhance its functionality and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty truck operation. The design incorporates precision engineering, with features such as balanced weight distribution and optimized belt/chain tension, which contribute to its efficient operation. Additionally, the assembly is designed to integrate seamlessly with Cummins engines, ensuring compatibility and ease of installation 3.

Benefits

The advantages of this part are manifold. Its robust construction and precise engineering contribute to improved engine performance, allowing for more efficient power transmission and reduced wear on connected components. The assembly’s durability ensures long-term reliability, even under the demanding conditions typical of heavy-duty truck use. Furthermore, its efficient design contributes to overall engine efficiency, potentially leading to fuel savings and reduced maintenance costs.

Installation Process

Installing the Crankshaft Pulley Assembly requires careful attention to detail to ensure proper function and longevity. The process involves aligning the assembly with the crankshaft, securing it in place, and ensuring the correct tension on the belts or chains connected to it. It is important to follow manufacturer guidelines closely, using the recommended tools and techniques to avoid common pitfalls such as misalignment or over-tightening, which can lead to premature wear or failure.

Troubleshooting and Maintenance

Common issues with the Crankshaft Pulley Assembly may include wear on the pulley surface, belt/chain slippage, or noise during operation. Diagnostic techniques involve visual inspection for wear or damage, checking belt/chain tension, and listening for unusual sounds that may indicate a problem. Regular maintenance, such as cleaning the assembly and ensuring proper belt/chain tension, can help prevent issues and ensure optimal performance. If problems are detected, it is advisable to consult a professional for repair or replacement 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry, particularly in the heavy-duty truck sector. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications, ensuring performance, durability, and efficiency.

Crankshaft Pulley Assembly (Part 3008808) Compatibility with Cummins Engines

The Crankshaft Pulley Assembly (Part 3008808) manufactured by Cummins is designed to fit seamlessly with specific Cummins engine models. This part is integral to the engine’s operation, ensuring the proper functioning of the engine’s ancillary systems.

K38 Engine Series

The K38 engine series, known for its robust performance and reliability, is compatible with the Crankshaft Pulley Assembly (Part 3008808). This compatibility ensures that the pulley assembly can effectively engage with the crankshaft, facilitating the smooth operation of the engine’s belt-driven components such as the alternator, water pump, and air conditioning compressor.

K50 Engine Series

Similarly, the K50 engine series benefits from the use of the Crankshaft Pulley Assembly (Part 3008808). This part is engineered to fit precisely with the K50 engines, ensuring optimal performance and longevity. The K50 series, recognized for its efficiency and power, relies on this pulley assembly to maintain the integrity of the engine’s timing and accessory systems.

Grouping for Compatibility

Both the K38 and K50 engine series share a commonality in their design and operational requirements, which makes the Crankshaft Pulley Assembly (Part 3008808) a suitable fit for both. This grouping highlights the versatility and broad applicability of the part across different engine models within the Cummins lineup.

Role of Part 3008808 Crankshaft Pulley Assembly in Engine Systems

The Part 3008808 Crankshaft Pulley Assembly is integral to the efficient operation of various engine systems. This assembly is primarily responsible for transmitting rotational force from the crankshaft to other engine components, ensuring smooth and consistent power delivery.

Integration with the Damper

The Crankshaft Pulley Assembly works in conjunction with the damper to mitigate rotational vibrations generated by the engine. The damper, often a part of the pulley assembly, absorbs these vibrations, preventing them from being transmitted to other engine components. This results in a more stable and reliable engine performance.

Interaction with Vibration Control Systems

In engines equipped with advanced vibration control systems, the Crankshaft Pulley Assembly plays a significant role. It helps in maintaining the balance of the engine by ensuring that the crankshaft’s rotational motion is uniform. This is particularly important in high-performance engines where even minor imbalances can lead to increased wear and reduced efficiency.

Contribution to Overall Engine Smoothness

By effectively managing the transmission of rotational force and minimizing vibrations, the Crankshaft Pulley Assembly contributes to the overall smoothness of engine operation. This is essential for both the longevity of the engine and the comfort of the vehicle’s occupants.

Conclusion

In summary, the Part 3008808 Crankshaft Pulley Assembly is a key component in ensuring that the engine operates efficiently and smoothly, working hand-in-hand with dampers and vibration control systems to maintain optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.