This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

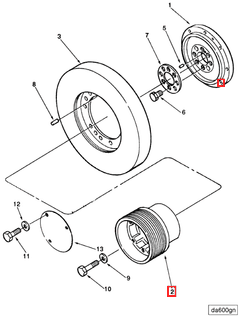

The Cummins 3028400 Crankshaft Pulley is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the transfer of power from the engine to various auxiliary systems. This pulley is significant in ensuring the smooth operation of these systems, contributing to the overall efficiency and performance of the truck.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is attached to the front of the crankshaft. Its primary function is to drive the serpentine belt, which in turn powers several engine accessories. These accessories include the alternator, power steering pump, and air conditioning compressor. The pulley helps maintain the proper tension and alignment of the serpentine belt, ensuring that these components receive the necessary power to operate effectively 1.

Role of the 3028400 Crankshaft Pulley in Truck Operation

The 3028400 Crankshaft Pulley plays a specific role in the operation of a truck by ensuring the efficient transfer of power from the engine to various auxiliary components. It is designed to work in harmony with the engine’s crankshaft, providing a stable and consistent drive for the serpentine belt. This consistent drive is vital for the reliable operation of the alternator, power steering pump, and air conditioning compressor, among other systems.

Key Features of the 3028400 Crankshaft Pulley

The design and construction features of the 3028400 Crankshaft Pulley enhance its performance and durability. It is composed of high-quality materials that provide strength and resistance to wear. The pulley is balanced to reduce vibrations and ensure smooth operation. Additionally, precise alignment features are incorporated to maintain the correct positioning of the serpentine belt, which is crucial for the efficient operation of the driven components 2.

Benefits of Using the 3028400 Crankshaft Pulley

The advantages provided by the 3028400 Crankshaft Pulley include improved engine efficiency, reduced wear on connected components, and enhanced overall performance of the truck. By ensuring a stable and consistent drive for the serpentine belt, this pulley helps maintain the optimal operation of the alternator, power steering pump, and air conditioning compressor. This results in a more reliable and efficient truck operation 3.

Installation Considerations

Proper installation of the 3028400 Crankshaft Pulley is important to ensure its effective function. Guidelines and best practices include adhering to torque specifications to secure the pulley correctly without over-tightening, which could lead to damage. Alignment checks are necessary to ensure the pulley is correctly positioned relative to the crankshaft and the serpentine belt. Compatibility with other engine components should also be verified to ensure seamless integration into the engine system.

Maintenance and Troubleshooting

Routine maintenance of the 3028400 Crankshaft Pulley involves regular inspections for signs of wear or damage, such as cracks or excessive play. Troubleshooting common issues, such as belt slippage or pulley wobble, may involve checking the tension and alignment of the serpentine belt, as well as inspecting the pulley for any signs of damage or imbalance.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and power generation equipment, Cummins has built a reputation for delivering reliable and high-performance products. The company’s focus on research and development ensures that its products, including the 3028400 Crankshaft Pulley, meet the demanding requirements of heavy-duty applications.

Compatibility of the 3028400 Crankshaft Pulley

The 3028400 Crankshaft Pulley is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is integral to the engine’s operation, as it drives the ancillary components such as the alternator, water pump, and air conditioning compressor.

K38 Engines

For the K38 engines, the 3028400 crankshaft pulley is specifically engineered to match the unique specifications of this engine model. The fitment process involves aligning the pulley with the crankshaft and securing it with the appropriate bolts and fasteners. The precision in manufacturing ensures that the pulley operates smoothly, reducing wear and tear on the engine components.

K50 Engines

Similarly, the K50 engines are compatible with the 3028400 crankshaft pulley. This part is designed to handle the specific demands of the K50 engine, providing a reliable connection between the crankshaft and the driven components. The compatibility is achieved through meticulous engineering, ensuring that the pulley fits snugly and operates efficiently.

Grouping Compatibility

In some cases, the 3028400 crankshaft pulley may also fit other engines within the same family or series. Cummins has a reputation for maintaining consistency across its engine lines, which allows for broader compatibility. This means that while the primary focus is on the K38 and K50 engines, there may be other engines that can also utilize this part, provided they share similar design characteristics.

Installation Considerations

When installing the 3028400 crankshaft pulley, it is crucial to follow the manufacturer’s guidelines to ensure proper fitment and function. This includes using the correct torque specifications for the bolts and ensuring that the pulley is aligned correctly with the crankshaft. Proper installation is key to preventing premature wear and maintaining the longevity of the engine components.

Role of the 3028400 Crankshaft Pulley in Engine Systems

The 3028400 Crankshaft Pulley is integral to the efficient operation of various engine systems. It serves as the primary driver for several auxiliary components, ensuring their synchronized function with the engine’s crankshaft.

Integration with the Vibration Damper

When paired with a vibration damper, the Crankshaft Pulley helps mitigate the torsional vibrations generated by the engine. The vibration damper, typically mounted between the pulley and the crankshaft, absorbs these vibrations, preventing them from being transmitted through the drivetrain. This results in smoother engine operation and reduced wear on connected components.

Driving Accessory Belts

The Crankshaft Pulley is responsible for driving accessory belts that power essential engine components such as the alternator, power steering pump, air conditioning compressor, and water pump. By maintaining consistent belt tension and speed, the pulley ensures these components operate efficiently, contributing to the overall performance and reliability of the engine system.

Synchronizing Engine Components

In engines equipped with timing belts or chains, the Crankshaft Pulley works in tandem with the camshaft pulley to maintain precise timing between the crankshaft and camshaft. This synchronization is vital for the proper opening and closing of engine valves in relation to the pistons’ movement, ensuring optimal combustion and engine efficiency.

Enhancing Engine Balance

The design of the Crankshaft Pulley also plays a role in enhancing the engine’s balance. By counteracting the rotational forces generated by the crankshaft, the pulley helps minimize vibrations and smoothen the engine’s operation. This balance is particularly important in high-performance engines where precision and stability are paramount.

Conclusion

The 3028400 Crankshaft Pulley is a key component in the engine system, facilitating the operation of various auxiliary components and contributing to the engine’s overall balance and efficiency. Proper installation, maintenance, and understanding of its role in the engine system are essential for ensuring the longevity and performance of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.