This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

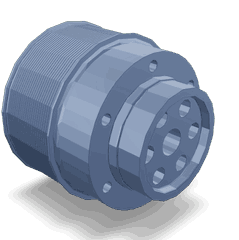

The Cummins 3086167 Crankshaft Pulley is a component designed for use in commercial trucks equipped with Cummins engines. This pulley plays a significant role in the operation of these vehicles by facilitating the transfer of power from the engine to various accessories. Understanding its function and importance can help in maintaining the efficiency and reliability of the truck’s engine system.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a device attached to the front of an engine’s crankshaft. Its primary function is to drive engine accessories such as the alternator, power steering pump, and air conditioning compressor through a series of belts. The pulley helps in reducing torsional vibrations that occur during engine operation, thereby contributing to smoother engine performance and longevity 1.

Purpose of the Cummins 3086167 Crankshaft Pulley

The Cummins 3086167 Crankshaft Pulley is integral to the operation of a truck’s engine. It is responsible for transferring rotational force from the crankshaft to the aforementioned engine accessories via a belt drive system. This transfer of power ensures that these accessories function correctly, which is vital for the overall performance and comfort of the vehicle.

Key Features

The Cummins 3086167 Crankshaft Pulley is engineered with specific features to enhance its performance and durability. It is constructed from high-quality materials that can withstand the rigors of commercial truck operation. The pulley’s design includes precision-machined grooves to ensure a secure fit of the belts, minimizing slippage and maximizing efficiency. Additionally, it incorporates a dampening system to reduce vibrations, contributing to a smoother engine operation 2.

Benefits

The use of the Cummins 3086167 Crankshaft Pulley offers several advantages. It contributes to improved engine efficiency by ensuring that power is effectively transferred to the accessories. The pulley’s design and materials enhance the reliability and longevity of the engine system, reducing the need for frequent replacements or repairs. Furthermore, by minimizing vibrations, it helps in maintaining the overall health of the engine components.

Installation and Compatibility

Proper installation of the Cummins 3086167 Crankshaft Pulley is crucial for its effective operation. It is designed to be compatible with specific Cummins engine models, ensuring a precise fit and function. Installation procedures should follow manufacturer guidelines to avoid damage to the pulley or engine components.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3086167 Crankshaft Pulley is important to ensure its optimal performance. This includes checking for signs of wear or damage, ensuring the belts are properly tensioned, and addressing any issues promptly. Common problems may include belt slippage or pulley misalignment, which can be resolved through adjustments or replacements as necessary.

Performance Enhancements

The Cummins 3086167 Crankshaft Pulley contributes to the overall performance of the engine by ensuring efficient power transfer to accessories. This can lead to improvements in torque output and fuel efficiency, as the engine operates more smoothly and with reduced vibrations 3.

Safety Considerations

When working with the Cummins 3086167 Crankshaft Pulley, it is important to observe safety protocols. This includes ensuring the engine is off and cooled down before beginning any work, using appropriate tools and equipment, and following manufacturer guidelines to prevent accidents and injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the industry, Cummins is committed to delivering high-quality components that meet the demanding requirements of commercial and industrial applications.

Compatibility with Cummins Engines

The Cummins crankshaft pulley part number 3086167 is designed to fit a variety of Cummins engines, ensuring compatibility and reliability across different engine models. Here is a detailed look at the engines with which this part is compatible:

K19 Series Engines

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

The 3086167 crankshaft pulley is engineered to fit seamlessly with the K19 series engines, specifically the QSK19 CM2350 K114 and QSK19 CM2350 K144G models. These engines are known for their robust performance and efficiency, and the pulley ensures that the crankshaft operates smoothly, reducing wear and tear.

QSK19 Series Engines

- QSK19 CM500

- QSK19 CM850 MCRS

The 3086167 crankshaft pulley is also compatible with the QSK19 series engines, including the QSK19 CM500 and QSK19 CM850 MCRS. These engines are designed for heavy-duty applications, and the pulley’s design helps maintain optimal engine performance by ensuring the crankshaft operates at the correct speed and alignment.

QSK19G Series Engine

- QSK19G

Lastly, the 3086167 crankshaft pulley is suitable for the QSK19G engine. This model is part of the QSK19G series, which is known for its versatility and reliability in various industrial applications. The pulley’s fit ensures that the engine’s crankshaft functions efficiently, contributing to the overall performance and longevity of the engine.

Role of Part 3086167 Crankshaft Pulley in Engine Systems

The Part 3086167 Crankshaft Pulley is an integral component within the engine system, facilitating the transfer of rotational force from the crankshaft to various auxiliary components. This pulley is engineered to work in harmony with the crankshaft, ensuring efficient operation of the engine’s accessory drive system.

Integration with the Vibration Damper

The crankshaft pulley is directly connected to the vibration damper, which plays a significant role in minimizing torsional vibrations produced by the engine. The damper consists of a drive plate, a driven plate, and an elastomeric layer that absorbs vibrations. The pulley’s precise fit and alignment with the damper ensure smooth transmission of power while reducing wear and tear on the crankshaft and connected components.

Contribution to the Accessory Drive Arrangement

Within the accessory drive arrangement, the crankshaft pulley serves as the primary driver for the engine’s auxiliary systems. It is responsible for transferring rotational energy to the serpentine belt, which in turn drives components such as the alternator, power steering pump, air conditioning compressor, and water pump. The efficient operation of these accessories is dependent on the consistent and reliable performance of the crankshaft pulley.

Ensuring Smooth Operation

The interaction between the crankshaft pulley and the vibration damper is essential for maintaining the overall balance and stability of the engine. By effectively managing vibrations, the damper prolongs the lifespan of the crankshaft and other engine components. The pulley’s role in this system is to provide a stable and consistent rotational force, ensuring that the damper can perform its function without interference.

Enhancing Engine Performance

The crankshaft pulley’s design and material properties are tailored to withstand the high stresses and dynamic loads encountered in engine operation. Its integration with the vibration damper and the accessory drive arrangement contributes to the engine’s overall performance, reliability, and durability. By facilitating the smooth and efficient transfer of power, the pulley helps to optimize the engine’s operation, leading to improved fuel efficiency and reduced emissions.

Conclusion

The Cummins 3086167 Crankshaft Pulley is a critical component in the efficient operation of Cummins engines. Its role in transferring power to engine accessories, reducing vibrations, and ensuring smooth engine operation underscores its importance in maintaining engine performance and reliability. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this part.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.