This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

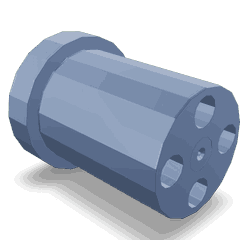

The Cummins 3089083 Idler Shaft is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the smooth operation of the truck’s drivetrain by maintaining proper belt tension and alignment. This shaft contributes to the efficient transfer of power and plays a significant role in the overall performance and reliability of the vehicle 1.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component used in various systems to guide or tension a belt or chain. In the context of a truck’s drivetrain, the idler shaft helps to keep the belt properly aligned and tensioned, ensuring efficient power transmission from the engine to other components such as the alternator, water pump, and air conditioning compressor. The idler shaft operates by rotating in sync with the belt, adjusting its position to maintain optimal tension and alignment 2.

Role of the 3089083 Idler Shaft in Truck Operation

The Cummins 3089083 Idler Shaft is integral to the operation of a truck’s accessory drive system. It interacts with the serpentine belt, ensuring that the belt remains taut and correctly aligned as it drives various engine accessories. This interaction contributes to the overall efficiency and performance of the truck by ensuring that these accessories operate smoothly and reliably. The idler shaft’s role in maintaining belt tension also helps to reduce wear and tear on both the belt and the accessories it drives 3.

Key Features of the 3089083 Idler Shaft

The Cummins 3089083 Idler Shaft is characterized by several key features that enhance its functionality and durability. These include a robust material composition, typically involving high-strength alloys that resist wear and corrosion. The design elements of the shaft, such as its precise machining and balanced construction, ensure smooth operation and minimal vibration. Additionally, any unique characteristics, such as specialized coatings or treatments, further contribute to its longevity and performance under demanding conditions 4.

Benefits of Using the 3089083 Idler Shaft

Utilizing the Cummins 3089083 Idler Shaft offers several advantages. These include improved performance and reliability of the truck’s accessory drive system, leading to enhanced overall vehicle efficiency. The shaft’s durable construction and precise engineering contribute to reduced maintenance requirements and lower operational costs. Furthermore, its ability to maintain optimal belt tension and alignment helps to prevent premature wear on other components, extending their service life 1.

Troubleshooting Common Issues with Idler Shafts

Common issues with idler shafts may include symptoms such as unusual noises, belt slippage, or visible wear on the shaft or belt. These problems can arise from factors like improper installation, lack of lubrication, or natural wear over time. Addressing these issues involves inspecting the shaft and belt for signs of damage, ensuring proper alignment and tension, and applying appropriate lubrication. In cases of significant wear or damage, replacement of the idler shaft may be necessary to restore optimal performance 2.

Maintenance Tips for the 3089083 Idler Shaft

To ensure the longevity and optimal performance of the Cummins 3089083 Idler Shaft, regular maintenance is recommended. This includes periodic inspection of the shaft and belt for signs of wear or damage, ensuring that the belt remains properly tensioned and aligned. Lubrication guidelines should be followed to keep the shaft operating smoothly, and replacement intervals should be observed to prevent failure due to wear. Adhering to these maintenance practices helps to maintain the efficiency and reliability of the truck’s accessory drive system 3.

Integration with Other Truck Components

The Cummins 3089083 Idler Shaft interacts with various components within the truck’s drivetrain, including the serpentine belt, tensioner, and driven accessories such as the alternator and water pump. This integration ensures that power is efficiently transmitted from the engine to these accessories, contributing to the overall performance and reliability of the vehicle. The dependencies and synergies between these components highlight the importance of proper installation and maintenance of the idler shaft to ensure optimal system performance 4.

Historical Development of Idler Shafts in Trucking

The evolution of idler shaft technology in the trucking industry has seen significant advancements over the years. Early designs were simpler and less durable, often requiring frequent maintenance and replacement. Modern idler shafts, like the Cummins 3089083, benefit from improved materials, precision manufacturing techniques, and innovative design features. These advancements have contributed to increased durability, reliability, and efficiency, enhancing the performance of heavy-duty trucks 1.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted provider of high-quality components for the automotive and heavy-duty truck markets. The company’s core competencies include engine technology, emissions solutions, and aftermarket services, positioning it as a leader in the industry. Cummins’ commitment to innovation and customer satisfaction has solidified its reputation as a reliable partner for businesses worldwide 2.

Idler Shaft 3089083 Compatibility with Cummins Engines

The Idler Shaft part number 3089083, manufactured by Cummins, is designed to fit seamlessly within a variety of their engine models. This component plays a role in maintaining the balance and efficiency of the engine’s operation by reducing friction and wear on moving parts.

QSK45 CM500 and QSK60 CM500

The Idler Shaft 3089083 is compatible with the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their reliability and performance in heavy-duty applications. The 3089083 part ensures smooth operation by properly aligning and supporting the engine’s internal components.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The Idler Shaft 3089083 also fits the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines. These models are equipped with advanced features and technologies, making them suitable for demanding industrial and marine applications. The 3089083 part is engineered to handle the specific requirements of these engines, ensuring longevity and consistent performance.

QSK60G

For the QSK60G engine, the Idler Shaft 3089083 is a component that supports the engine’s operation. This engine model is designed for high-performance applications, and the 3089083 part ensures that all moving parts function smoothly and efficiently.

QSK78 CM500

The Idler Shaft 3089083 is also compatible with the QSK78 CM500 engine. This engine is part of Cummins’ high-output series, offering exceptional power and efficiency. The 3089083 part is designed to integrate perfectly with the QSK78 CM500, providing the necessary support and alignment for optimal engine performance.

By ensuring that the Idler Shaft 3089083 is correctly installed in these engines, operators can maintain the efficiency and reliability of their equipment, reducing the risk of unexpected downtime and costly repairs 3.

Role of Part 3089083 Idler Shaft in Engine Systems

The Part 3089083 Idler Shaft is a component in the orchestration of various engine systems, ensuring smooth operation and efficient power transmission.

In the cylinder block, the idler shaft works in conjunction with the crankshaft and bearings to maintain the timing and synchronization of the engine’s moving parts. It helps in distributing the rotational force generated by the crankshaft to other components, ensuring that the pistons move in a coordinated manner within the cylinders.

Within the gear housing, the idler shaft plays a role in the transmission of power. It assists in changing the direction of rotation between gears, allowing for efficient power transfer from the crankshaft to the drive system. This is particularly important in multi-cylinder engines where precise timing and power distribution are necessary for optimal performance.

The idler shaft also interacts with the fuel pump system. In engines where the fuel pump is driven by the camshaft or a separate gear train, the idler shaft ensures that the pump receives consistent rotational force. This consistent force is vital for maintaining a steady fuel supply to the engine, which is essential for combustion efficiency and overall engine performance.

Additionally, the idler shaft is involved in the operation of the drive system. It helps in transferring power from the engine to other ancillary components such as the alternator, water pump, and power steering pump. This ensures that these components receive the necessary power to function correctly, contributing to the engine’s overall reliability and efficiency 4.

Conclusion

The Cummins 3089083 Idler Shaft is a critical component in the efficient operation of heavy-duty trucks. Its role in maintaining belt tension and alignment, along with its integration with various engine systems, ensures smooth and reliable performance. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall efficiency and reliability of the vehicle.

-

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ ↩ ↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008

↩ ↩ ↩ -

Combustion Engine Diagnosis, Rolf Isermann, Springer Vieweg, 2017

↩ ↩ ↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif Ed, Springer Vieweg, 2014

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.