This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

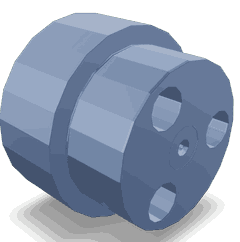

The Cummins 3089104 Idler Shaft is a critical component in commercial trucks, essential for the smooth operation of the engine’s timing system. It maintains the proper tension on the timing belt or chain, ensuring that the engine’s valves operate at the correct times, which is fundamental for engine performance and efficiency 3.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component that guides or tensions a belt or chain in various systems. In a truck’s engine, it ensures the timing belt or chain remains correctly tensioned, maintaining synchronization between the camshaft and crankshaft. This synchronization is vital for the precise operation of the engine’s valves relative to the piston’s position, directly impacting engine performance 1.

Role of the 3089104 Idler Shaft in Truck Operation

The Cummins 3089104 Idler Shaft is integral to a truck’s engine operation. It interacts with the timing belt or chain to ensure proper tension, maintaining precise timing between the camshaft and crankshaft. This ensures the engine’s valves operate correctly, contributing to the vehicle’s overall performance and efficiency 3.

Key Features of the 3089104 Idler Shaft

This Cummins part is characterized by its robust design and high-quality materials, engineered to withstand the high stresses and temperatures in a truck’s engine. Its design includes precision-machined surfaces and bearings for smooth operation and reduced friction, contributing to its durability and reliability in demanding applications 2.

Benefits of Using the 3089104 Idler Shaft

Using the Cummins 3089104 Idler Shaft in a truck’s engine offers advantages such as improved engine efficiency through optimal tension on the timing belt or chain, reduced wear on other components, and enhanced engine durability. Its precise engineering helps maintain engine performance, contributing to the vehicle’s reliability and longevity 3.

Troubleshooting and Maintenance Suggestions

Common issues with the 3089104 Idler Shaft include bearing wear or misalignment, affecting the timing belt or chain’s tension. Regular inspection and maintenance are recommended, including checking for wear or damage, ensuring proper alignment, and replacing the idler shaft if necessary. Adhering to the manufacturer’s maintenance schedule can prevent issues and ensure efficient engine operation 1.

Installation and Replacement Procedures

When installing or replacing the 3089104 Idler Shaft, it is crucial to follow the manufacturer’s instructions. This may involve removing the timing belt or chain, aligning the idler shaft with the engine’s timing marks, and ensuring it is securely fastened. Special tools may be required for precise alignment and tensioning. Careful attention to these steps ensures the idler shaft functions correctly, contributing to the engine’s performance 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader known for its quality, innovation, and customer satisfaction in the commercial truck industry. The company designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. Its extensive product range and focus on reliability make it a preferred choice for commercial vehicle operators and manufacturers 3.

Role of Part 3089104 Idler Shaft in Engine Systems

The idler shaft, identified by part number 3089104, is integral to the timing system of an engine. Its primary function is to maintain the correct alignment and tension of the timing chain or belt, ensuring smooth and precise operation of the engine’s moving parts 3.

Interaction with the Cylinder Block

Within the cylinder block, the idler shaft works with the crankshaft and camshaft to keep the timing chain taut. This tension is vital for the accurate timing of valve operations, directly influencing the engine’s performance and efficiency. The idler shaft is typically mounted on the cylinder block, supporting the timing chain and reducing slack, which could otherwise lead to timing issues 1.

Coordination with the Crankshaft and Bearings

The crankshaft converts the linear motion of the pistons into rotational motion. The idler shaft interacts with the crankshaft through the timing chain or belt. Proper alignment and tension provided by the idler shaft ensure that the crankshaft’s rotation is accurately transmitted to the camshaft, maintaining the engine’s timing integrity. The bearings supporting the idler shaft must be in optimal condition to allow for smooth rotation and minimal friction, contributing to the overall efficiency of the engine 2.

Integration with the Gear Housing

In engines with a gear-driven camshaft, the idler shaft plays a role in the gear housing. It helps maintain the correct mesh between the timing gears, ensuring that the camshaft follows the crankshaft’s rotation precisely. This interaction is essential for the proper opening and closing of the valves in sync with the pistons’ movement, which is fundamental for the engine’s combustion process 3.

Overall Engine Harmony

The idler shaft’s role extends beyond individual components; it contributes to the harmonious operation of the entire engine system. By ensuring the timing chain or belt remains taut and aligned, it facilitates the precise coordination between the crankshaft, camshaft, and valves. This precision is essential for optimal engine performance, fuel efficiency, and longevity 3.

Conclusion

The Cummins 3089104 Idler Shaft is a vital component in the operation of commercial truck engines. Its role in maintaining the correct tension and alignment of the timing belt or chain is crucial for the engine’s performance, efficiency, and longevity. Regular maintenance and proper installation are key to ensuring the idler shaft functions correctly, contributing to the overall reliability and performance of the vehicle.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ ↩ ↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ ↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.