This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3533025 Shaft Wheel Rotor is a component designed for use in the braking systems of commercial trucks. It plays a role in ensuring the safe and efficient operation of these vehicles by contributing to the overall braking performance. Understanding its purpose and functionality is key to maintaining the reliability and safety of commercial trucks.

Basic Concepts of Shaft Wheel Rotors

A Shaft Wheel Rotor is a component within a vehicle’s braking system. It consists of a rotor disc that is attached to the wheel hub, and it works in conjunction with brake pads to slow down or stop the vehicle. When the brake pedal is pressed, hydraulic pressure is applied to the brake pads, which then clamp onto the rotor, creating friction that slows the wheel’s rotation 1.

Purpose of the 3533025 Shaft Wheel Rotor

The 3533025 Shaft Wheel Rotor is designed to interact with the brake pads within the truck’s braking system. Its primary function is to provide a surface for the brake pads to grip, thereby converting kinetic energy into thermal energy through friction, which in turn slows down the vehicle. This component ensures that the braking system operates effectively, contributing to the overall safety and performance of the truck 2.

Key Features

The 3533025 Shaft Wheel Rotor is characterized by its robust design and the materials used in its construction. It is typically made from high-quality cast iron or similar materials that offer excellent heat dissipation and wear resistance. The rotor’s design may include ventilation features to enhance cooling, which is vital for maintaining performance during prolonged use or under heavy loads 3.

Benefits

Using the 3533025 Shaft Wheel Rotor offers several advantages. It provides improved braking efficiency due to its design and material properties. The rotor’s durability ensures long-term reliability, reducing the frequency of replacements. Additionally, its precise engineering contributes to consistent braking performance, which is crucial for the safety of commercial truck operations 4.

Installation Process

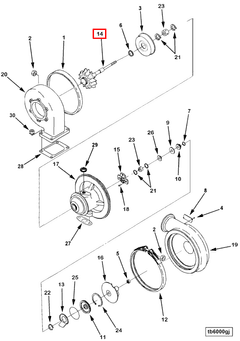

Installing the 3533025 Shaft Wheel Rotor requires careful attention to ensure proper fitting and function. The process involves removing the old rotor, cleaning the hub surface, and then mounting the new rotor. It is important to use the correct tools and follow the manufacturer’s guidelines to avoid damage and ensure the rotor is securely attached. Proper torque specifications must be adhered to during the installation to maintain the integrity of the braking system.

Maintenance Tips

To ensure the optimal performance and longevity of the 3533025 Shaft Wheel Rotor, regular maintenance is recommended. This includes inspecting the rotor for signs of wear, warping, or damage, and cleaning it to remove any debris that could affect braking performance. It is also important to check the rotor’s thickness regularly to ensure it meets the minimum requirements for safe operation.

Troubleshooting Common Issues

Common issues with the 3533025 Shaft Wheel Rotor may include warping, cracking, or excessive wear. These problems can often be identified through visual inspection or by noticing changes in braking performance. Addressing these issues promptly by repairing or replacing the rotor as necessary is important to maintain the safety and efficiency of the braking system.

Performance Under Various Conditions

The 3533025 Shaft Wheel Rotor is designed to perform under a range of driving conditions. It can handle heavy loads and operate effectively in extreme temperatures. However, its performance may vary depending on the specific conditions it is subjected to, such as frequent stops in heavy traffic or descending steep grades. Understanding these factors can help in making informed decisions about maintenance and replacement schedules.

Compatibility With Other Systems

The 3533025 Shaft Wheel Rotor is engineered to be compatible with a variety of braking systems and truck models. This compatibility ensures that it can be integrated into different setups without requiring significant modifications. When selecting a rotor, it is important to consider the specific requirements of the truck’s braking system to ensure optimal performance and safety.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a leading provider of diesel engines, related technologies, and customer support.

Cummins Shaft Wheel Rotor 3533025 Compatibility

The Cummins Shaft Wheel Rotor part number 3533025 is designed to fit seamlessly with several of Cummins’ engine models. This part is integral to the engine’s operation, ensuring precise timing and synchronization of various engine components.

K38

The K38 engine benefits from the precision and reliability of the 3533025 Shaft Wheel Rotor. This rotor is engineered to match the K38’s specific requirements, providing a stable and efficient rotational mechanism that is crucial for the engine’s performance.

NH/NT 855

For the NH/NT 855 engines, the 3533025 Shaft Wheel Rotor is a perfect fit. This rotor ensures that the engine’s camshaft and crankshaft are synchronized correctly, which is vital for the smooth operation of the NH/NT 855 series.

QSM11 CM570 and QSN14 CM876 N103

Both the QSM11 CM570 and QSN14 CM876 N103 engines are designed to work optimally with the 3533025 Shaft Wheel Rotor. This rotor is crafted to handle the specific demands of these engines, ensuring that the rotational components are precisely aligned and operate without issues.

QST30 CM552

The QST30 CM552 engine also integrates the 3533025 Shaft Wheel Rotor effectively. This rotor is a key component in maintaining the engine’s timing and synchronization, which is essential for the QST30 CM552’s performance and longevity.

Each of these engines relies on the 3533025 Shaft Wheel Rotor to maintain the necessary precision and efficiency in their operations. This rotor’s design ensures that it fits perfectly with the specified engines, providing a reliable and durable solution for maintaining engine performance.

Role of Part 3533025 Shaft Wheel Rotor in Engine Systems

The 3533025 Shaft Wheel Rotor is an integral component in the efficient operation of various engine systems. Its primary function is to facilitate the rotation of the turbocharger’s compressor and turbine wheels, ensuring optimal airflow and pressure within the engine.

Integration with Turbocharger Components

-

Turbocharger Core: The Shaft Wheel Rotor is central to the turbocharger core, connecting the compressor wheel to the turbine wheel. This connection allows for the transfer of rotational energy from the exhaust gases to the compressor, enhancing air intake efficiency.

-

Turbocharger Kit: When installed as part of a turbocharger kit, the Shaft Wheel Rotor ensures that the compressor and turbine wheels spin in unison. This synchronization is essential for maintaining the balance and performance of the turbocharger system.

Interaction with Engine Components

-

Cylinder Head: The efficient operation of the Shaft Wheel Rotor directly impacts the cylinder head by ensuring a consistent supply of pressurized air. This pressurized air is vital for combustion, directly influencing engine performance and power output.

-

Connecting Rod: Although indirectly related, the performance of the connecting rod is enhanced by the efficient operation of the Shaft Wheel Rotor. Improved airflow and pressure from the turbocharger lead to better combustion, which in turn reduces stress on the connecting rod.

Contribution to Aftermarket and Performance Enhancements

-

Aftermarket Turbocharger: In aftermarket turbocharger setups, the Shaft Wheel Rotor plays a significant role in achieving higher performance levels. Its precise engineering ensures that the turbocharger operates within optimal parameters, contributing to increased engine power and efficiency.

-

Performance Parts: When combined with other performance parts, the Shaft Wheel Rotor helps in fine-tuning the engine’s airflow and pressure dynamics. This results in enhanced overall engine performance, making it a key component in high-performance engine builds.

Role in Cooling Systems

-

Aftercooler: The Shaft Wheel Rotor indirectly supports the aftercooler by ensuring that the air entering the cooling system is at the right pressure and temperature. This contributes to the effective cooling of the compressed air, which is crucial for maintaining engine efficiency and preventing overheating.

-

Core Assembly and Heat Exchangers: In systems utilizing core assemblies and heat exchangers (such as the Core Assembly Heat Exchanger60 and Core Assembly Heat Exchanger60W), the Shaft Wheel Rotor ensures that the air passing through these components is optimally pressurized. This enhances the efficiency of heat exchange processes, contributing to overall engine cooling and performance.

Conclusion

In summary, the 3533025 Shaft Wheel Rotor is a pivotal component that enhances the functionality and performance of various engine systems, from turbochargers to cooling assemblies. Its role in ensuring synchronized rotation and efficient airflow is fundamental to achieving optimal engine performance.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Saiful Bari. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩ -

TK Garrett, K Newton, W Steeds. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Wolf-Henning Schneider. Pistons and Engine Testing. Springer Nature, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.