This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3536624 Shaft Wheel Rotor is a component designed for use in the braking systems of commercial trucks. It plays a role in ensuring the safe and efficient operation of these vehicles by contributing to the braking mechanism. Understanding its function and importance is key to maintaining the performance and safety of commercial trucks.

Basic Concepts of Shaft Wheel Rotors

A shaft wheel rotor is a part of a truck’s braking system. It consists of a rotor disc that is attached to the wheel hub and spins with the wheel. When the brake is applied, the brake pads clamp down on the rotor, creating friction that slows the wheel’s rotation, thus aiding in stopping the vehicle. The rotor’s design and material are crucial for dissipating heat generated during braking and ensuring consistent performance 1.

Purpose and Role in Truck Operation

This Cummins part provides a surface for the brake pads to contact. This interaction is fundamental for converting kinetic energy into thermal energy through friction, which in turn slows down the vehicle. The rotor must work in harmony with other braking components, such as calipers and brake pads, to deliver effective braking performance.

Key Features

The 3536624 is characterized by its material composition, typically a high-quality cast iron or similar alloy, which offers excellent heat resistance and durability. Its design may include ventilation features to enhance cooling and reduce the risk of brake fade. The rotor is engineered to withstand the rigors of commercial truck use, including heavy loads and frequent braking.

Benefits

Using this part can lead to improved braking efficiency, as its design and material properties contribute to better heat dissipation and consistent friction. The rotor’s durability ensures long-term reliability, reducing the frequency of replacements and maintenance costs. It is built to perform under various operating conditions, providing dependable braking performance.

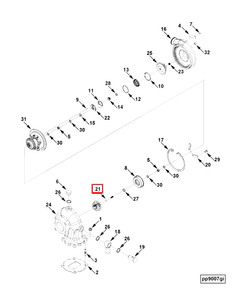

Installation Process

Installing the 3536624 requires careful attention to detail. The process involves removing the old rotor, ensuring the wheel hub is clean and free of debris, and then mounting the new rotor. Proper torque specifications must be followed to secure the rotor in place. Alignment checks are necessary to ensure the rotor is properly seated and the brake system functions correctly.

Troubleshooting Common Issues

Common issues with shaft wheel rotors include warping, cracking, or uneven wear. These problems can arise from excessive heat, improper installation, or normal wear and tear. Troubleshooting steps may involve inspecting the rotor for damage, checking for proper alignment, and ensuring the brake system is functioning correctly. Solutions could range from resurfacing the rotor to replacing it if damage is severe.

Maintenance Tips

Regular maintenance of the 3536624 is vital for its longevity and performance. This includes periodic inspections for signs of wear or damage, cleaning the rotor to remove any brake dust or debris, and ensuring that the braking system is properly lubricated and aligned. Adhering to manufacturer-recommended inspection intervals will help maintain optimal braking performance.

Performance in Various Conditions

The 3536624 is designed to perform under a range of driving conditions. Whether dealing with heavy loads, extreme temperatures, or varied terrains, the rotor’s material and design contribute to its ability to provide reliable braking performance. Its heat dissipation capabilities are particularly important in preventing brake fade during prolonged use or in challenging conditions.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products including engines, filtration, and power generation equipment. With a history of innovation and quality, Cummins has built a reputation for reliability and performance in the commercial vehicle sector. The company’s commitment to excellence is reflected in its product offerings, including the 3536624.

Compatibility

This part is designed to fit into a variety of engine models, ensuring seamless integration and optimal performance. It is crucial for the proper functioning of the engine’s components, particularly in the areas of fuel injection and timing.

Compatible Engines

- 6B5.9 and 6C8.3 Engines

This part is compatible with the 6B5.9 and 6C8.3 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The rotor’s precision engineering ensures that it aligns perfectly with the engine’s camshaft, facilitating smooth and accurate valve timing.

- QSB5.9 CM850 and QSB6.7 M CM2250 Engines

For the QSB5.9 CM850 and QSB6.7 M CM2250 engines, this part is also a perfect fit. These engines are part of the QSB series, which is renowned for its versatility and efficiency. The rotor’s design is tailored to meet the specific requirements of these engines, ensuring that they operate at peak performance levels.

Integration and Functionality

When installed in any of these engines, the 3536624 plays a pivotal role in the engine’s operation. It works in conjunction with the camshaft to control the timing of the fuel injection process. This synchronization is critical for maintaining the engine’s efficiency and power output.

The rotor’s high-quality materials and precise manufacturing ensure that it can withstand the rigors of continuous operation, providing long-lasting performance and reliability. Its compatibility with multiple engine models makes it a versatile component, suitable for a wide range of applications.

Role in Engine Systems

This part is an integral component in the operation of various engine systems, particularly in enhancing the performance and efficiency of turbochargers.

In an Aftermarket Turbocharger setup, the Shaft Wheel Rotor facilitates the transfer of energy from the exhaust gases to the compressor wheel. This energy transfer is essential for increasing the air intake into the engine, thereby boosting power output without significantly increasing fuel consumption.

Within the Core Assembly of a turbocharger, the Shaft Wheel Rotor plays a pivotal role. It connects the turbine wheel, which is driven by exhaust gases, to the compressor wheel. This connection ensures that as the turbine wheel spins, it drives the compressor wheel at high speeds, compressing the intake air before it enters the engine cylinders.

In a Core Assembly Heat Exchanger 40W, the Shaft Wheel Rotor’s efficiency is paramount. The heat exchanger is designed to cool the compressed air from the turbocharger, reducing its temperature and increasing its density. The Shaft Wheel Rotor must operate smoothly to maintain the balance between the turbine and compressor, ensuring optimal heat exchange and air compression.

For a Turbocharger, the Shaft Wheel Rotor is the backbone of its operation. It ensures that the energy harnessed from the exhaust gases is effectively transferred to the compressor, allowing for increased air intake and, consequently, enhanced engine performance.

In a Turbocharger Core, the Shaft Wheel Rotor’s precision and durability are essential. The core is the heart of the turbocharger, and the Shaft Wheel Rotor’s role in connecting and synchronizing the turbine and compressor wheels is vital for the core’s overall functionality.

Lastly, in a Turbocharger Kit, which often includes the turbocharger core, heat exchanger, and additional components, the Shaft Wheel Rotor ensures that all elements work in harmony. Its role in transferring energy and maintaining the balance between the turbine and compressor is key to the kit’s effectiveness in boosting engine performance.

Conclusion

The Cummins 3536624 Shaft Wheel Rotor is a critical component in both the braking systems of commercial trucks and the operation of various engine systems, particularly turbochargers. Its design, material composition, and precise engineering ensure reliable performance and efficiency in a wide range of applications. Regular maintenance and proper installation are essential to maximize its benefits and ensure the safety and performance of the vehicles it serves.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.