This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3594952 Shaft Wheel Rotor is a component designed for use in heavy-duty trucks. It serves a significant role in the braking system, contributing to the overall safety and performance of the vehicle. Understanding its purpose and functionality is key to appreciating its importance in truck operations.

Basic Concepts of Shaft Wheel Rotors

A shaft wheel rotor is a component within a vehicle’s braking system. It consists of a disc that is attached to the wheel hub, rotating with the wheel. When the brake is applied, the caliper squeezes the brake pads against the rotor, creating friction that slows down the wheel. The efficiency and reliability of this process are vital for the safe operation of the vehicle 1.

Role of the 3594952 Shaft Wheel Rotor in Truck Operation

The 3594952 Shaft Wheel Rotor plays a role in the braking system by providing a surface for the brake pads to contact. This interaction is what enables the truck to slow down or stop. The rotor must be able to withstand high temperatures and repeated stress without warping or cracking, ensuring consistent braking performance 2.

Key Features of the 3594952 Shaft Wheel Rotor

The 3594952 Shaft Wheel Rotor is characterized by its material composition, typically a high-quality cast iron or similar alloy, which offers durability and heat resistance. Its design may include ventilation features to enhance cooling, and it is precision-machined to ensure smooth operation and compatibility with brake components 3.

Benefits of Using the 3594952 Shaft Wheel Rotor

Utilizing the 3594952 Shaft Wheel Rotor can lead to improved braking performance, increased durability, and enhanced reliability. These benefits contribute to safer driving conditions and reduced maintenance requirements, making it a valuable component for heavy-duty truck applications.

Installation Process

Installing the 3594952 Shaft Wheel Rotor requires careful attention to ensure proper fitment and function. The process involves removing the old rotor, cleaning the hub, and mounting the new rotor securely. It is important to use the correct tools and follow manufacturer guidelines to avoid damage and ensure safety.

Maintenance and Troubleshooting

Regular maintenance of the 3594952 Shaft Wheel Rotor includes inspection for wear, cracks, or warping. It is also important to check for proper alignment and secure mounting. Common issues may include noise during braking or reduced braking efficiency, which can often be addressed through inspection and timely replacement if necessary.

Performance Enhancements

The 3594952 Shaft Wheel Rotor contributes to overall truck performance by providing reliable and efficient braking. Its design and material properties help to ensure that the braking system operates effectively under various conditions, enhancing both efficiency and safety.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive industry, known for its wide range of products, including heavy-duty truck components. With a strong reputation for quality and innovation, Cummins continues to be a leader in providing reliable and high-performance parts for the automotive sector.

Cummins Shaft Wheel Rotor Part 3594952 Compatibility

The Cummins Shaft Wheel Rotor part number 3594952 is designed to fit seamlessly within several of Cummins’ engine models. This part is integral to the operation of these engines, ensuring precise timing and synchronization of various engine components.

N14 CELECT PLUS and N14 MECHANICAL Engines

The Shaft Wheel Rotor part 3594952 is compatible with both the N14 CELECT PLUS and N14 MECHANICAL engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as construction and transportation. The rotor’s design ensures that it can handle the high torque and rotational speeds typical of these engines, maintaining accuracy and durability over time.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines also benefit from the use of the Cummins Shaft Wheel Rotor part 3594952. These engines are typically employed in agricultural and industrial settings, where consistent power and reliability are paramount. The rotor’s precision engineering ensures that it can withstand the demanding conditions of these environments, providing smooth and reliable operation.

QSK38 CM850 MCRS Engines

The QSK38 CM850 MCRS engines, another series where the Shaft Wheel Rotor part 3594952 is applicable, are designed for high-performance applications. These engines are often used in marine and power generation sectors, where they must operate under extreme conditions. The rotor’s design allows it to maintain its integrity and performance, ensuring that the engine runs smoothly and efficiently, even under the most challenging conditions.

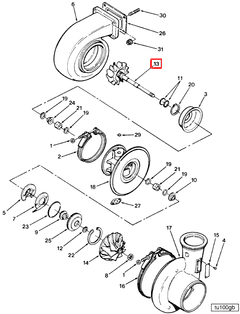

Role of Part 3594952 Shaft Wheel Rotor in Engine Systems

The 3594952 Shaft Wheel Rotor is an integral component in various engine systems, ensuring efficient operation and performance. Its role can be observed in the following components:

-

Aftermarket Turbocharger: The Shaft Wheel Rotor is essential in the turbocharger’s operation, where it helps in spinning the turbine and compressor wheels, thus increasing the engine’s airflow and power output.

-

Assembly Core: Within the assembly core, the Shaft Wheel Rotor ensures smooth rotation and balance, which is vital for the durability and efficiency of the core components.

-

Cam Follower Housing: The Shaft Wheel Rotor interacts with the cam follower housing to maintain precise timing and synchronization between the camshaft and the valve train, enhancing engine performance.

-

Campaign Kit: In campaign kits, which often include upgrades or replacements for critical engine parts, the Shaft Wheel Rotor plays a role in improving the overall reliability and performance of the engine.

-

Camshaft: The Shaft Wheel Rotor works in conjunction with the camshaft to ensure accurate valve timing, which is fundamental for optimal combustion and engine efficiency.

-

Camshaft Right Bank: Similar to its interaction with the primary camshaft, the Shaft Wheel Rotor ensures that the right bank camshaft operates smoothly, contributing to balanced engine performance.

-

Connecting Rod and Piston: The Shaft Wheel Rotor’s precise rotation helps in maintaining the synchronization between the crankshaft and the connecting rod and piston assembly, ensuring smooth engine operation.

-

Core Assembly Heat3B: In the Heat3B turbocharger core assembly, the Shaft Wheel Rotor is responsible for the efficient transfer of energy from the exhaust gases to the compressor, enhancing turbo performance.

-

Core Assembly Heat60: For the Heat60 core assembly, the Shaft Wheel Rotor ensures that the turbocharger operates within its designed parameters, providing consistent boost pressure.

-

Core Assembly HT3B (DCM): In the HT3B (DCM) core assembly, the Shaft Wheel Rotor’s role is to maintain the turbocharger’s efficiency and reliability under varying operating conditions.

-

Cylinder Head: The Shaft Wheel Rotor’s interaction with the cylinder head components ensures that the valve timing is accurate, which is essential for proper combustion and engine performance.

-

Dataplate: Although the dataplate itself does not interact with the Shaft Wheel Rotor, the information it provides can be used to ensure that the correct Shaft Wheel Rotor is installed for the specific engine configuration.

-

EBM: Performance Parts: In performance parts provided by EBM, the Shaft Wheel Rotor is often upgraded to handle increased stress and higher RPMs, contributing to enhanced engine performance.

-

EBM: Turbocharger: Within EBM turbochargers, the Shaft Wheel Rotor is a key component that ensures the turbocharger can deliver increased airflow and boost pressure.

-

Heat3B Turbocharger: In the Heat3B turbocharger, the Shaft Wheel Rotor’s role is to ensure efficient energy transfer and smooth operation, contributing to the turbocharger’s overall performance.

-

Injector: While the injector itself does not directly interact with the Shaft Wheel Rotor, the precise engine timing ensured by the Shaft Wheel Rotor contributes to optimal fuel delivery and combustion.

-

Injector Plumbing: Proper engine timing facilitated by the Shaft Wheel Rotor ensures that the injector plumbing operates efficiently, contributing to consistent fuel delivery.

-

Performance Parts: In various performance parts, the Shaft Wheel Rotor is often upgraded to enhance engine responsiveness and power output.

-

Turbocharger: The Shaft Wheel Rotor is a fundamental component in any turbocharger, responsible for spinning the turbine and compressor wheels to increase engine airflow and power.

-

Turbocharger Core: Within the turbocharger core, the Shaft Wheel Rotor ensures that the core components operate efficiently and reliably.

-

Turbocharger Kit: In a turbocharger kit, the Shaft Wheel Rotor is a critical component that ensures the turbocharger can deliver increased performance and reliability.

Conclusion

The Cummins 3594952 Shaft Wheel Rotor is a critical component in heavy-duty truck braking systems, offering durability, reliability, and enhanced performance. Its compatibility with various Cummins engine models underscores its versatility and importance in ensuring safe and efficient truck operations. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing its benefits and ensuring optimal vehicle performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.