This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

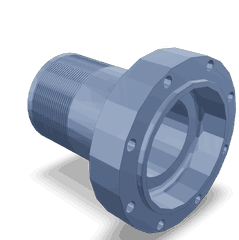

The Crankshaft Pulley 3626580, manufactured by Cummins, is a component designed for use in commercial truck engines. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance engine components. This part is significant in the context of truck engines due to its role in facilitating the operation of various engine accessories and contributing to the overall efficiency and performance of the engine.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a component attached to the front of an engine’s crankshaft. Its primary function is to drive various engine accessories such as the alternator, power steering pump, and air conditioning compressor through a series of belts or chains. The crankshaft pulley operates by converting the rotational motion of the crankshaft into a driving force for these accessories, ensuring they function correctly and efficiently within the truck’s powertrain 1.

Purpose of the 3626580 Crankshaft Pulley

The 3626580 Crankshaft Pulley plays a role in the operation of a truck by providing a stable and efficient means of transferring power from the crankshaft to the engine’s accessory belt system. It interacts with other engine components by ensuring that the belts remain properly tensioned and aligned, which is crucial for the reliable operation of engine accessories. This pulley contributes to overall engine performance by reducing vibrations and ensuring smooth operation of the accessory drive system 2.

Key Features

The primary characteristics of the 3626580 Crankshaft Pulley include its robust design, which is engineered to withstand the high stresses and vibrations inherent in commercial truck engines. It is constructed from durable materials that offer resistance to wear and corrosion, ensuring longevity and reliable performance. Unique attributes of this pulley may include advanced damping technologies that help minimize vibrations and noise, enhancing both the durability and efficiency of the engine 3.

Benefits

The advantages provided by the 3626580 Crankshaft Pulley include improved engine efficiency and reliability. By ensuring that engine accessories are properly driven, it contributes to the smooth and efficient operation of the engine. Specific performance enhancements may include reduced wear on belts and accessories, leading to longer service intervals and lower maintenance costs.

Installation and Compatibility

Proper installation of the 3626580 Crankshaft Pulley requires adherence to manufacturer guidelines to ensure it is correctly aligned and secured to the crankshaft. Tools and equipment necessary for installation may include a pulley removal tool and a torque wrench to ensure proper tightening of fasteners. Compatibility with various truck models and engine types should be verified to ensure optimal performance and reliability.

Maintenance and Troubleshooting

Routine maintenance practices for the 3626580 Crankshaft Pulley involve regular inspection for signs of wear or damage, such as cracks or excessive play. Common issues that may arise include belt slippage or pulley misalignment, which can be addressed by adjusting belt tension or realigning the pulley. Troubleshooting tips include checking for proper alignment and tension, and replacing worn or damaged components as necessary to maintain efficient operation.

Performance Enhancements

The 3626580 Crankshaft Pulley contributes to overall engine performance by ensuring that engine accessories are efficiently driven, which can lead to improvements in power, torque, and fuel efficiency. Specific enhancements may include reduced parasitic losses from the accessory drive system, allowing the engine to operate more efficiently and with greater reliability.

Safety Considerations

When working with the 3626580 Crankshaft Pulley, it is important to observe safety protocols and precautions. This includes ensuring the engine is off and cooled down before beginning any work, using appropriate personal protective equipment, and following proper handling, installation, and maintenance procedures to ensure safe operation and prevent injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a reputation for quality and reliability, Cummins is committed to manufacturing high-quality automotive components that meet the demanding requirements of commercial and industrial applications. Their products are designed to deliver performance, efficiency, and durability, making them a preferred choice for professionals in the automotive industry.

Crankshaft Pulley Compatibility with Cummins Engines

The Crankshaft Pulley part number 3626580, manufactured by Cummins, is designed to fit a specific range of Cummins engines. This part is integral to the engine’s operation, ensuring the proper functioning of the crankshaft and the ancillary systems it drives.

K50 and QSK50 CM2150 K107

The Crankshaft Pulley part 3626580 is compatible with the K50 engine, as well as the QSK50 CM2150 K107 engine. These engines share similar design parameters that allow the pulley to interface seamlessly with the crankshaft, ensuring efficient power transfer and system operation.

QSK50 CM2150 MCRS and QSK50 CM2350 K108

Similarly, the Crankshaft Pulley part 3626580 is also compatible with the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. These engines, while distinct in some specifications, maintain the necessary alignment and mounting features that allow the pulley to fit and function correctly.

By ensuring that the Crankshaft Pulley part 3626580 is used with the specified engines, users can maintain optimal engine performance and longevity.

Role of Part 3626580 Crankshaft Pulley in Engine Systems

The Part 3626580 Crankshaft Pulley is an integral component in the efficient operation of engine systems. It is primarily responsible for driving various ancillary components through the use of belts or chains.

When the engine operates, the crankshaft pulley is driven by the crankshaft itself. This pulley, in turn, drives the damper, which is designed to absorb and reduce the vibration generated by the engine. The damper, often incorporating a vibration damper, plays a significant role in maintaining the smooth operation of the engine by minimizing the oscillatory movements that can occur due to the combustion process.

The crankshaft pulley also engages with the vibration damper to ensure that the rotational energy from the crankshaft is transferred efficiently to other components such as the alternator, power steering pump, and air conditioning compressor. This transfer of energy is vital for the operation of these components, which rely on a consistent and smooth supply of mechanical power to function correctly.

In summary, the Part 3626580 Crankshaft Pulley works in conjunction with the damper and vibration damper to ensure that the engine operates smoothly and that ancillary components receive the necessary mechanical power to perform their functions effectively.

Conclusion

The 3626580 Crankshaft Pulley by Cummins is a critical component in the operation of commercial truck engines, ensuring the efficient transfer of power to engine accessories and contributing to overall engine performance and reliability. Its robust design, compatibility with specific Cummins engines, and role in reducing vibrations make it an essential part of the engine system. Proper installation, maintenance, and adherence to safety protocols are vital for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.