This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

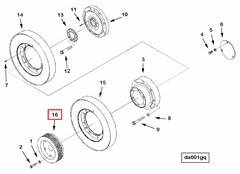

The Cummins 3630334 Crankshaft Pulley is a component designed for use in commercial trucks, playing a significant role in the operation of the engine. This part is integral to the efficient functioning of the truck’s powertrain, ensuring that various engine-driven accessories receive the necessary power to operate.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. Its primary function is to transfer rotational force from the crankshaft to other engine components, such as the alternator, power steering pump, and air conditioning compressor, via a belt or chain drive system. This transfer of force is essential for the operation of these accessories, which are vital for the truck’s performance and driver comfort 1.

Purpose of the Cummins 3630334 Crankshaft Pulley

The Cummins 3630334 Crankshaft Pulley serves as a link in the engine’s drive system. It interacts with the crankshaft to drive the serpentine belt, which in turn powers various engine accessories. This pulley’s role in the engine’s operation contributes to the overall performance and efficiency of the truck, ensuring that all driven components function as intended.

Key Features

The Cummins 3630334 Crankshaft Pulley is characterized by its robust design and high-quality materials. It features a durable construction that can withstand the rigors of commercial truck operation. The pulley is designed with precision to ensure a perfect fit and optimal performance. Its materials are chosen for their strength and resistance to wear, contributing to the pulley’s longevity and reliability.

Benefits

The use of the Cummins 3630334 Crankshaft Pulley offers several advantages. It enhances engine efficiency by ensuring smooth and reliable power transmission to engine accessories. Its durable construction contributes to the reliability and longevity of the truck’s engine, reducing the need for frequent replacements. For truck operators and fleet managers, this means lower maintenance costs and increased uptime.

Installation and Compatibility

Proper installation of the Cummins 3630334 Crankshaft Pulley is crucial for its effective operation. It requires precise alignment and secure fastening to the crankshaft. While specific installation procedures may vary depending on the truck model and engine type, it is generally recommended to follow the manufacturer’s guidelines for the best results. Compatibility with various truck models and engine types ensures that this pulley can be a versatile choice for fleet managers.

Troubleshooting and Maintenance

Common issues with crankshaft pulleys can include wear, misalignment, or damage to the pulley’s teeth. Regular inspection and maintenance are recommended to identify and address these issues promptly. Maintenance practices may include checking the pulley’s alignment, inspecting for wear or damage, and ensuring the serpentine belt is in good condition. These practices help maintain optimal performance and extend the pulley’s lifespan.

Performance Enhancements

For those looking to enhance engine performance, modifications to the Cummins 3630334 Crankshaft Pulley may be considered. Adjustments to pulley sizing or material upgrades can potentially improve engine efficiency and power output. However, any modifications should be approached with caution and ideally performed by professionals to ensure compatibility and safety.

Safety Considerations

When working with the Cummins 3630334 Crankshaft Pulley, it is important to observe safety precautions. This includes using the appropriate tools and equipment for installation and maintenance, ensuring the engine is off and cool before beginning work, and following all manufacturer guidelines. Proper handling and installation procedures minimize the risk of injury or damage to the component and the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry for innovation and quality, Cummins is committed to providing reliable and efficient solutions for its customers. The company’s dedication to excellence is reflected in its wide range of automotive components, including the Cummins 3630334 Crankshaft Pulley.

Cummins Crankshaft Pulley Part 3630334 Compatibility

The Cummins crankshaft pulley part number 3630334 is a critical component designed to interface with the crankshaft of various engines, ensuring the smooth operation of the engine’s accessory systems. This pulley is engineered to fit seamlessly with the following Cummins engines:

K50 Series Engines

The K50 series engines are known for their robust design and reliability, commonly used in heavy-duty applications. The crankshaft pulley part 3630334 is specifically crafted to match the unique specifications of these engines, ensuring optimal performance and longevity.

Grouping of Compatible Engines

While the K50 series is a notable example, the crankshaft pulley part 3630334 is also compatible with other Cummins engines that share similar design and operational parameters. This compatibility extends to various models within the Cummins engine lineup, ensuring that the pulley can be used across multiple platforms without modification.

The design of the part ensures that it can handle the torque and rotational forces exerted by the engine, providing a stable and efficient means of transferring power to the engine’s accessories, such as the alternator, water pump, and air conditioning compressor.

This compatibility is achieved through precise engineering and adherence to strict manufacturing standards, ensuring that the part fits snugly and operates smoothly within the engine’s ecosystem.

Role of Part 3630334 Crankshaft Pulley in Engine Systems

The Part 3630334 Crankshaft Pulley is an integral component in the efficient operation of various engine systems. Its primary function is to drive multiple auxiliary components through a series of belts or chains.

Interaction with the Damper

The Crankshaft Pulley is directly connected to the engine’s crankshaft, which experiences significant torsional vibrations due to the combustion process. To mitigate these vibrations, a damper is often integrated into the pulley design. The damper absorbs and dissipates the torsional energy, ensuring smoother operation and reducing wear on the crankshaft and connected components. This results in enhanced engine longevity and reliability.

Vibration Management

In addition to the damper, the Crankshaft Pulley plays a significant role in overall vibration management within the engine system. By maintaining a consistent rotational speed and minimizing fluctuations, the pulley helps in stabilizing the engine’s operation. This stability is essential for the precise timing of fuel injection, ignition, and valve operations, all of which are sensitive to variations in crankshaft speed.

Driving Auxiliary Components

The Crankshaft Pulley is responsible for driving essential auxiliary components such as the alternator, power steering pump, and air conditioning compressor. It ensures these components receive the necessary rotational force to function correctly. The pulley’s design, including its grooves and harmonic balance, is tailored to transmit power efficiently while minimizing energy loss and wear.

Enhancing Engine Performance

By effectively managing vibrations and driving auxiliary components, the Crankshaft Pulley contributes to the overall performance and efficiency of the engine. Smooth operation reduces the likelihood of mechanical failures and enhances the engine’s ability to deliver consistent power output. This, in turn, leads to better fuel economy and reduced emissions, aligning with modern engineering goals for efficiency and sustainability.

Conclusion

The Cummins 3630334 Crankshaft Pulley is a vital component in the operation of commercial truck engines, ensuring the efficient transfer of power to essential engine accessories. Its robust design, compatibility with various Cummins engines, and role in vibration management and performance enhancement make it a reliable choice for fleet managers and truck operators. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.