This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3632542 Centrifuge Shaft is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the separation of contaminants from the engine oil, thereby contributing to the overall efficiency and longevity of the engine 1.

Basic Concepts of Centrifuge Shafts

A centrifuge shaft is a component found in centrifuge systems, which are used to separate substances of different densities by spinning them at high speeds. In industrial and automotive contexts, centrifuge shafts are integral to systems that purify fluids by removing impurities and contaminants. They operate on the principle of centrifugal force, where the rotation causes heavier particles to move outward and settle, allowing cleaner fluid to be collected 2.

Purpose of the 3632542 Centrifuge Shaft

This part is specifically designed to function within the centrifuge system of a truck’s engine. Its purpose is to rotate at high speeds to separate contaminants from the engine oil. This separation process ensures that the oil remains clean, which is vital for the lubrication and cooling of engine components, thus supporting the engine’s performance and durability.

Key Features

The 3632542 is constructed from high-quality materials that are resistant to wear and corrosion. Its design includes precision-machined surfaces to ensure smooth operation and longevity. Unique characteristics such as balanced weight distribution and robust construction enhance its performance and reliability in demanding truck engine environments.

Benefits

The use of the 3632542 offers several advantages. It contributes to improved engine efficiency by ensuring that the oil remains free of contaminants. This clean oil facilitates better lubrication and cooling of engine parts, which can lead to enhanced performance and extended engine life. Additionally, the shaft’s durable construction reduces the need for frequent replacements, offering cost-effectiveness over time.

Installation Process

Installing the 3632542 requires careful attention to detail. The process involves securing the shaft within the centrifuge housing, ensuring it is properly aligned and balanced. Tools such as torque wrenches may be necessary to tighten components to the manufacturer’s specifications. It is important to follow the installation instructions provided by Cummins to ensure proper function and safety.

Common Issues and Troubleshooting

Common issues with the 3632542 may include imbalance, wear, or contamination. Symptoms of these problems can manifest as unusual noises, decreased performance, or oil contamination. Troubleshooting steps may involve inspecting the shaft for signs of wear, rebalancing if necessary, and ensuring that the centrifuge system is clean and free of debris.

Maintenance Tips

Regular maintenance of the 3632542 is important for its longevity and performance. This includes periodic inspections for wear or damage, ensuring that the shaft is properly balanced, and keeping the centrifuge system clean. Following the manufacturer’s maintenance schedule will help prevent issues and ensure optimal operation.

Compatibility and Applications

The 3632542 is designed for use in specific Cummins engine models and centrifuge systems. It is compatible with a range of commercial truck applications where efficient oil purification is required. Its use is particularly beneficial in trucks that operate in harsh conditions or require extended oil change intervals.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial transportation.

Centrifuge Shaft Part 3632542 Compatibility with Cummins Engines

This Cummins part is a critical component in several of their engine models. It is designed to fit seamlessly within the engine architecture, ensuring optimal performance and reliability. Here is a detailed look at its compatibility with various Cummins engines:

QSK45 CM500 and QSK60 CM500

This part is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are known for their robust design and high power output, making them suitable for heavy-duty applications. The part’s precision engineering ensures it integrates smoothly with the engine’s internal mechanisms, contributing to the overall efficiency and longevity of the engine.

QSK60 CM850 MCRS and QSK60G

Similarly, the Centrifuge Shaft is also compatible with the QSK60 CM850 MCRS and QSK60G engines. These engines are part of Cummins’ advanced lineup, offering enhanced performance and reliability. The part’s design is tailored to fit these engines, ensuring that it operates efficiently within the stringent requirements of these high-performance models.

QSK78 CM500

The QSK78 CM500 engine also benefits from the use of the Centrifuge Shaft. This engine is designed for maximum power and efficiency, making it ideal for demanding industrial applications. The part’s compatibility with this engine ensures that it meets the rigorous standards set by Cummins for durability and performance.

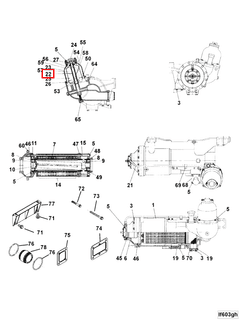

Understanding the Integration of Part 3632542 Centrifuge Shaft with Engine Systems

The Centrifuge Shaft is an integral component in the efficient operation of various engine systems. Its role is to facilitate the smooth rotation and balance of the centrifuge assembly, ensuring optimal performance and longevity of the engine.

Interaction with the Centrifuge Cover Kit

The Centrifuge Cover Kit is designed to encase the centrifuge assembly, protecting it from external contaminants and ensuring a sealed environment for operation. The Centrifuge Shaft fits precisely within this kit, allowing for secure attachment and rotation. This fitment ensures that the shaft remains aligned and protected, contributing to the overall efficiency and reliability of the centrifuge system.

Coordination with the Full Flow Oil Filter

The Full Flow Oil Filter is responsible for purifying the engine oil by removing impurities and contaminants. The Centrifuge Shaft plays a supportive role by maintaining the structural integrity and rotational stability of the centrifuge, which can be part of the oil filtration system in some engines. This ensures that the oil filter operates under consistent conditions, enhancing the filtration process and prolonging the life of the oil filter.

Synergy with the Lubricating Oil Filter

In engines where the centrifuge is integrated into the lubrication system, the Lubricating Oil Filter works in tandem with the Centrifuge Shaft. The shaft’s precise rotation helps in efficiently separating contaminants from the oil, allowing the filter to capture these particles more effectively. This collaboration ensures that the lubricating oil remains clean, reducing wear on engine components and enhancing overall engine performance.

Integration with the Lubricating Oil Filter Head

The Lubricating Oil Filter Head is the component that houses the oil filter and connects it to the engine’s lubrication system. The Centrifuge Shaft interfaces with this head, ensuring that the centrifuge operates within the specified parameters. This integration is vital for maintaining the pressure and flow rate of the oil, which are essential for proper lubrication of engine parts.

Conclusion

In summary, the 3632542 Centrifuge Shaft is a key element in the interplay between various engine components, ensuring that the centrifuge system operates smoothly and effectively within the engine’s lubrication and filtration systems. Its compatibility with specific Cummins engines and its role in maintaining clean engine oil contribute significantly to the efficiency, performance, and longevity of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.