This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

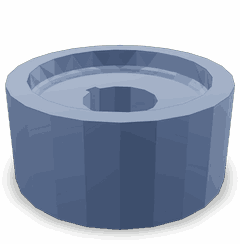

The Cummins 3638560 Crankshaft Pulley is a component designed for use in heavy-duty truck engines. It serves a significant role in the operation of these vehicles by facilitating the transfer of rotational force from the crankshaft to various engine accessories. Understanding its function and importance can provide valuable insights into the overall performance and maintenance of heavy-duty trucks.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a device attached to the front of an engine’s crankshaft. Its primary function is to drive engine accessories such as the alternator, power steering pump, and air conditioning compressor via a series of belts or chains. The pulley helps to smooth out the crankshaft’s rotational vibrations, contributing to a more stable engine operation. It interacts closely with the engine’s timing system and other components to ensure efficient power transmission 1.

Purpose of the Cummins 3638560 Crankshaft Pulley

This Cummins part is integral to the operation of a truck engine. It plays a role in driving various engine accessories by transferring rotational force from the crankshaft. This ensures that components such as the alternator, water pump, and other auxiliary systems receive the necessary power to function correctly. The pulley’s design allows it to manage the engine’s vibrations, contributing to smoother operation and reduced wear on connected components 2.

Key Features

The 3638560 is constructed with high-quality materials to ensure durability and performance. It features a robust design that includes a dampening element to absorb vibrations, which helps in maintaining engine stability. The pulley is engineered to withstand the high stresses and temperatures encountered in heavy-duty applications. Its precise manufacturing ensures a perfect fit and optimal performance within the engine system.

Benefits

This part offers several advantages. It contributes to improved engine performance by ensuring efficient power transfer to essential accessories. The pulley’s dampening feature helps reduce vibrations, leading to a smoother engine operation. Its durable construction ensures long-term reliability, even under demanding conditions. Additionally, the pulley’s efficient design can contribute to overall engine efficiency by minimizing energy loss during power transmission 3.

Installation Process

Installing the 3638560 requires careful attention to detail. The process involves removing the old pulley, ensuring the crankshaft is clean and free of debris, and then aligning the new pulley with the crankshaft. Proper tools, such as a pulley removal tool and a torque wrench, are necessary to secure the pulley correctly without overtightening. It is important to follow the manufacturer’s guidelines to ensure the pulley is installed to the correct specifications.

Troubleshooting Common Issues

Common issues with crankshaft pulleys can include excessive vibration, noise, or failure to drive accessories effectively. These problems may arise from wear and tear, improper installation, or manufacturing defects. Regular inspection can help identify early signs of pulley degradation. Solutions may involve rebalancing the pulley, ensuring proper alignment, or replacing the pulley if it is damaged beyond repair.

Maintenance Tips

To ensure the longevity and optimal performance of the 3638560, regular maintenance is recommended. This includes periodic inspection for signs of wear, ensuring all belts and connections are tight and in good condition, and addressing any unusual noises or vibrations promptly. Following the manufacturer’s maintenance schedule can help prevent unexpected failures and extend the life of the pulley.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s extensive product range serves various markets, from on-highway to off-highway applications, demonstrating its commitment to meeting the diverse needs of its customers.

Cummins Crankshaft Pulley Part 3638560 Compatibility

The Cummins crankshaft pulley part number 3638560 is designed to fit seamlessly with several of Cummins’ engine models. This part is crucial for the proper functioning of the engine’s accessory drive system, ensuring that components such as the alternator, water pump, and air conditioning compressor operate correctly.

QSK50 Engines

The QSK50 series, known for its robust performance and reliability, includes various models that are compatible with the 3638560 crankshaft pulley. This part ensures that the engine’s crankshaft is properly connected to the accessory drive system, maintaining optimal performance and efficiency.

CM2150 Engines

The CM2150 engines, which are part of Cummins’ medium-duty diesel engine lineup, also benefit from the 3638560 crankshaft pulley. This part is engineered to fit these engines precisely, ensuring that the accessory drive system functions without any issues. The CM2150 engines are known for their durability and efficiency, and the 3638560 crankshaft pulley plays a key role in maintaining these qualities.

MCRS Engines

The MCRS engines, which are part of Cummins’ medium-duty diesel engine family, are another series that is compatible with the 3638560 crankshaft pulley. This part is designed to fit these engines perfectly, ensuring that the accessory drive system operates smoothly and efficiently. The MCRS engines are known for their reliability and performance, and the 3638560 crankshaft pulley is essential for maintaining these characteristics.

By ensuring that the 3638560 crankshaft pulley is correctly installed, engine owners can maintain the performance and longevity of their QSK50, CM2150, and MCRS engines. This part is a critical component in the engine’s accessory drive system, and its proper installation is essential for the engine’s overall health and efficiency.

Role of Part 3638560 Crankshaft Pulley in Engine Systems

The 3638560 is an integral component in the efficient operation of various engine systems. It serves as the primary driver for several auxiliary components, ensuring their synchronized operation with the engine’s crankshaft.

Integration with the Damper

The crankshaft pulley works in conjunction with the damper to manage the rotational forces generated by the engine. The damper, typically a harmonic balancer, is attached to the front of the crankshaft. Its primary function is to absorb torsional vibrations produced during engine operation. The crankshaft pulley, when fitted correctly, ensures that the damper can effectively perform its role. This integration helps in maintaining a smooth and consistent rotational speed, which is essential for the reliable operation of the engine.

Interaction with Vibration Control Systems

In modern engine systems, vibration control is paramount to ensure longevity and performance. The crankshaft pulley plays a significant role in this aspect by transferring the rotational motion from the crankshaft to other components while minimizing the transmission of vibrations. This is particularly important for components like the alternator, power steering pump, and air conditioning compressor, which are often belt-driven. The pulley’s design and material properties are engineered to reduce the amplitude of vibrations, thereby protecting these sensitive components from undue stress and wear.

Synergy with Auxiliary Components

Beyond its primary function, the crankshaft pulley facilitates the operation of various auxiliary components. For instance, it drives the serpentine belt, which in turn powers the alternator, water pump, and other essential systems. The pulley’s precise fitting and alignment ensure that these components receive the necessary rotational force to function correctly. This synergy is vital for the overall efficiency and reliability of the engine system.

Conclusion

In summary, the 3638560 Crankshaft Pulley is a key element in the engine’s drivetrain, working seamlessly with the damper and vibration control systems to ensure smooth operation and longevity of the engine and its auxiliary components.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022.

↩ -

Engineering Mechanics: Statics, Libby Osgood, Gayla Cameron, and Emma Christensen, Creative Commons, 2024.

↩ -

The Dynamic Behavior of a Diesel Engine, S. A. Miedema, Z. Lu, Published by Drir S. A. Miedema, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.