This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

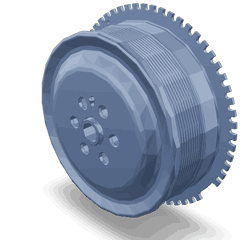

The Cummins 3696491 Crankshaft Pulley is a component designed for use in commercial trucks equipped with Cummins engines. This pulley is integral to the operation of the engine, facilitating the transfer of rotational force from the crankshaft to various auxiliary components. Its role in ensuring the efficient and reliable operation of the truck’s powertrain underscores its significance in commercial trucking applications 1.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. Its primary function is to drive the engine’s accessory belt(s), which in turn powers components such as the alternator, water pump, and air conditioning compressor. Within the context of a truck’s powertrain, the crankshaft pulley plays a vital role in maintaining the synchronization and operation of these critical systems 2.

Purpose of the Cummins 3696491 Crankshaft Pulley

The Cummins 3696491 Crankshaft Pulley serves to connect the crankshaft to the accessory drive belt, enabling the transfer of power to various engine components. This pulley is engineered to work in harmony with the engine’s crankshaft, ensuring smooth operation and efficient power transmission. Its design contributes to the overall performance and reliability of the engine, playing a part in the synchronization of engine accessories and the maintenance of optimal engine operation 3.

Key Features

The Cummins 3696491 Crankshaft Pulley is characterized by its robust design and high-quality materials, which enhance its functionality and durability. The pulley is crafted from materials that offer resistance to wear and corrosion, ensuring long-term performance in demanding commercial truck applications. Its design includes precision-machined teeth for secure belt engagement and a balanced construction to minimize vibrations.

Benefits

The Cummins 3696491 Crankshaft Pulley offers several advantages, including improved engine efficiency and reliability. Its durable construction and precise engineering contribute to the longevity of the component, reducing the need for frequent replacements. Compared to other crankshaft pulleys, the 3696491 model provides enhanced performance and compatibility with Cummins engines, ensuring optimal operation of the truck’s powertrain.

Installation and Compatibility

Proper installation of the Cummins 3696491 Crankshaft Pulley is crucial for ensuring its effective operation and the overall performance of the engine. Installation procedures may vary depending on the specific engine and truck model, but generally involve securing the pulley to the crankshaft and aligning it with the accessory drive belt. Compatibility with various Cummins engines and truck models ensures that this pulley can be used in a wide range of commercial trucking applications.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3696491 Crankshaft Pulley includes regular inspection for signs of wear or damage, ensuring proper belt tension, and lubrication of moving parts as necessary. Troubleshooting common issues such as belt slippage, pulley misalignment, or bearing wear involves identifying the root cause of the problem and taking corrective action, which may include adjustment, repair, or replacement of the pulley.

Performance Enhancements

Optimizing the performance of the Cummins 3696491 Crankshaft Pulley can involve adjustments to pulley sizing or the use of upgraded materials. These modifications can enhance engine performance by improving power transmission efficiency, reducing vibrations, and increasing the durability of the pulley. Careful consideration of the specific requirements of the engine and truck application is necessary when implementing performance enhancements.

Safety Considerations

When working with the Cummins 3696491 Crankshaft Pulley, it is important to observe safety precautions and best practices. This includes proper handling of the component to prevent damage, securing the pulley during maintenance to avoid accidents, and being aware of potential hazards such as moving parts or high temperatures. Adhering to these safety guidelines ensures a safe working environment and protects the integrity of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for excellence in the automotive industry. The company’s dedication to advancing technology and improving product performance is evident in its wide range of engine components, including the Cummins 3696491 Crankshaft Pulley.

Crankshaft Pulley 3696491 Compatibility with Cummins Engines

The Crankshaft Pulley part number 3696491, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is integral to the engine’s operation, ensuring the smooth transfer of power from the crankshaft to the engine’s ancillary systems.

Compatible Engines

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

These engines share a commonality in their design and specifications, allowing the 3696491 crankshaft pulley to be a suitable fit. The shared architecture ensures that the pulley can effectively interface with the crankshaft, providing the necessary grip and alignment for optimal performance.

- X11 CM2670 X126B

- X12 CM2670 X121B

- X12N CMMDG1 X143B

- X13 CM2670 X122B

These engines, while part of a different series, also benefit from the 3696491 crankshaft pulley. The design of this pulley is versatile enough to accommodate the unique characteristics of these engines, ensuring reliable operation and longevity.

Grouping by Engine Series

The engines can be grouped into two main series based on their compatibility with the 3696491 crankshaft pulley:

-

CM Series Engines:

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

-

X Series Engines:

- X11 CM2670 X126B

- X12 CM2670 X121B

- X12N CMMDG1 X143B

- X13 CM2670 X122B

This grouping highlights the broad applicability of the 3696491 crankshaft pulley across different engine series, making it a valuable component for maintenance and repair purposes.

Role of Part 3696491 Crankshaft Pulley in Engine Systems

The 3696491 Crankshaft Pulley is an integral component in the orchestration of various engine systems, ensuring smooth and efficient operation.

Integration with the Damper

The crankshaft pulley works in tandem with the damper to mitigate the torsional vibrations generated by the engine’s reciprocating components. As the crankshaft rotates, it experiences alternating accelerations and decelerations due to the combustion cycles. The damper, typically a harmonic balancer, absorbs these torsional vibrations, preventing them from being transmitted through the crankshaft. The crankshaft pulley, being the outermost part of the damper assembly, facilitates this process by providing a mounting point for the damper. It ensures that the damper can effectively engage with the crankshaft, thus maintaining a stable rotational speed and reducing wear on connected components.

Interaction with Vibration Control Systems

In more advanced engine systems, the crankshaft pulley also plays a role in the overall vibration control strategy. It is often designed to work with other vibration-dampening components, such as rubber isolators or additional balancing weights. These systems aim to further reduce the vibrations that could otherwise lead to increased noise, decreased efficiency, and potential damage to engine mounts and ancillary components.

The pulley’s design—which may include specific grooves or patterns—helps in the efficient transfer of rotational force while minimizing the transmission of unwanted vibrations. This is particularly important in high-performance engines where the forces and vibrations are more pronounced.

Synergy with Ancillary Components

Beyond its primary role, the crankshaft pulley also serves as a connection point for various ancillary components. It typically features splines or keyways that allow for the attachment of belts driving accessories like the alternator, power steering pump, and air conditioning compressor. The smooth and consistent rotation provided by the pulley ensures that these components receive a steady supply of mechanical energy, which is essential for their reliable operation.

Conclusion

In summary, the 3696491 Crankshaft Pulley is a key player in maintaining the balance and efficiency of engine systems. Its interaction with the damper and vibration control components, as well as its role in driving ancillary systems, underscores its importance in the overall functionality of the engine.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Pin Dowel | 1 | 3681054 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.