This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3819920 Idler Shaft is a component designed for use in commercial trucks. It serves a specific function within the engine’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the performance of commercial trucks.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component used in various systems to change the direction of a belt or chain, maintain tension, and ensure proper alignment of other moving parts. In the context of a truck’s engine, the idler shaft operates by interacting with the engine’s timing system, helping to synchronize the movement of the camshaft and crankshaft 1.

Purpose of the 3819920 Idler Shaft

The Cummins 3819920 Idler Shaft plays a role in the engine’s operation by maintaining the correct tension and alignment of the timing belt or chain. This ensures that the camshaft and crankshaft operate in sync, which is vital for the engine’s performance. By keeping the timing components properly aligned, the idler shaft contributes to the smooth and efficient operation of the engine 2.

Key Features

The Cummins 3819920 Idler Shaft is characterized by its robust design and the use of high-quality materials. These features enhance its durability and performance. The shaft is engineered to withstand the high stresses and temperatures within the engine compartment, ensuring long-term reliability.

Benefits of Using the 3819920 Idler Shaft

Incorporating the Cummins 3819920 Idler Shaft into a truck’s engine system can lead to improved engine efficiency. It reduces wear on other components by maintaining optimal tension and alignment of the timing system. This can result in enhanced overall performance and reliability of the truck 3.

Installation Considerations

Proper installation of the Cummins 3819920 Idler Shaft is important for its effective operation. This process involves ensuring the engine is properly prepared, using the correct tools, and following a sequence of steps to fit the shaft correctly. Attention to detail during installation helps to prevent issues and ensures the shaft functions as intended.

Troubleshooting Common Issues

Common problems associated with idler shafts include noise, vibration, or failure. These issues can often be traced back to improper installation, wear, or damage. Diagnosing these problems involves a systematic approach to identify the root cause, whether it be a faulty component or incorrect setup. Resolving these issues may require adjustment, repair, or replacement of the idler shaft.

Maintenance Tips

Regular maintenance is key to prolonging the life of the Cummins 3819920 Idler Shaft. This includes periodic inspections to check for signs of wear, ensuring proper lubrication, and replacing the shaft when necessary. Adhering to these practices helps maintain the efficiency and reliability of the truck’s engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles.

Idler Shaft (Part 3819920) Compatibility with Cummins Engines

The Idler Shaft, identified by the part number 3819920, is a critical component in the engine systems of various Cummins engines. This part is designed to work seamlessly with a range of Cummins engine models, ensuring smooth operation and longevity of the engine’s mechanical components.

ISM CM570 and QSM11 CM570

The Idler Shaft is compatible with the ISM CM570 and QSM11 CM570 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The 3819920 part fits into the engine’s design, supporting the engine’s balance and reducing wear on other components.

ISM11 CM876 SN

For the ISM11 CM876 SN engine, the Idler Shaft is engineered to integrate perfectly with the engine’s architecture. This engine variant is designed for high efficiency and power, making the 3819920 part essential for maintaining the engine’s operational integrity.

L10 Series

The L10 CELECT, L10 GAS, and L10 MECHANICAL engines also utilize the Idler Shaft part 3819920. These engines are known for their versatility and are used in a variety of applications, from construction to marine. The 3819920 part ensures that the engine’s moving parts operate smoothly, enhancing the overall performance and lifespan of the engine.

M11 Series

The M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines are designed for high performance and efficiency. The Idler Shaft part 3819920 is a crucial component in these engines, providing the necessary support and balance to the engine’s moving parts. This ensures that the engine operates at peak efficiency, reducing wear and tear on other components.

Each of these engines benefits from the Idler Shaft part 3819920, ensuring that the engine’s components work in harmony, providing reliable performance and durability.

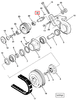

Role of Part 3819920 Idler Shaft in Engine Systems

The 3819920 Idler Shaft is an integral component in the efficient operation of various engine systems. It is primarily responsible for maintaining tension in the drive belt system, ensuring smooth and consistent power transmission to auxiliary components.

In systems involving the drive fan, the idler shaft plays a significant role by keeping the belt properly tensioned. This ensures that the fan operates efficiently, providing adequate cooling to the engine. Without proper tension, the belt may slip, leading to inefficient fan operation and potential engine overheating.

When integrated with the drive fan and fan clutch mounting kit, the idler shaft helps in maintaining the necessary tension for the fan clutch to engage and disengage smoothly. This is essential for optimal engine cooling under varying load conditions.

The idler (painted) pulley and idler pulley are directly influenced by the idler shaft. These pulleys rely on the idler shaft to keep the belt at the correct tension, which is vital for the reliable operation of components like the alternator, water pump, and air conditioning compressor.

In more complex assemblies such as the idler top-level assembly pulley, the idler shaft ensures that multiple belts within the system are tensioned correctly. This is particularly important in engines with serpentine belt configurations, where a single belt drives multiple components.

Additionally, the backside idler pulley often works in conjunction with the idler shaft to provide additional tensioning points within the belt system. This setup is common in engines where space is limited, and traditional tensioning methods are not feasible.

Overall, the 3819920 Idler Shaft is a key component in ensuring that the drive belt system operates efficiently, thereby supporting the reliable function of various engine-driven accessories.

Conclusion

The Cummins 3819920 Idler Shaft is a vital component in the engine systems of commercial trucks, contributing to the efficiency and reliability of the vehicle. Its role in maintaining tension and alignment within the timing system ensures smooth operation of the engine. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engines are essential for maximizing the performance and lifespan of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.