This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

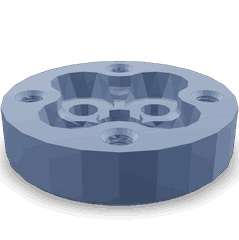

The Cummins 3905820 Crankshaft Flange is a critical component designed to enhance the operation of heavy-duty truck engines. Its role is significant in ensuring the smooth functioning of the engine, particularly in relation to the crankshaft and flywheel. Understanding its purpose and functionality is essential for maintaining engine efficiency and performance.

Basic Concepts of Crankshaft Flange

A crankshaft flange is a part that attaches to the end of the crankshaft. Its primary function is to provide a mounting surface for the flywheel, which is essential for the operation of the engine’s starting system 1. The flange also plays a role in maintaining the alignment and balance of the crankshaft, contributing to the overall stability and performance of the engine 2.

Purpose of the 3905820 Crankshaft Flange

The 3905820 Crankshaft Flange is integral to the operation of a truck engine. It interfaces directly with the flywheel, facilitating the transfer of rotational force from the crankshaft to the transmission system. This component contributes to engine balance by ensuring the crankshaft is properly aligned and supported. Its design also aids in reducing vibrations, which can enhance engine performance and longevity 3.

Key Features

The 3905820 Crankshaft Flange is characterized by its robust design and high-quality material composition. It is engineered to withstand the demanding conditions of heavy-duty truck engines. The flange features precise machining for optimal fit and function, and its material is chosen for durability and resistance to wear. These attributes ensure that the flange can perform reliably under high stress and temperature conditions 4.

Benefits

The use of the 3905820 Crankshaft Flange offers several advantages. It contributes to improved engine efficiency by ensuring smooth operation of the crankshaft and flywheel. The flange’s durable construction enhances the engine’s reliability, reducing the likelihood of failures. Additionally, its design helps in maintaining engine balance, which can lead to better overall performance and reduced maintenance needs 5.

Installation Process

Installing the 3905820 Crankshaft Flange requires careful attention to detail. The process involves aligning the flange with the crankshaft and securing it in place using the appropriate fasteners. It is important to use the correct tools and follow the manufacturer’s guidelines to ensure a proper fit. Careful inspection after installation is recommended to confirm that the flange is correctly positioned and securely fastened 6.

Troubleshooting Common Issues

Common issues with the 3905820 Crankshaft Flange may include misalignment or wear. Misalignment can lead to inefficient engine operation and increased wear on other components. Regular inspection can help identify these issues early. If wear is detected, the flange may need to be replaced to prevent further damage to the engine 7.

Maintenance Tips

To ensure the longevity and optimal performance of the 3905820 Crankshaft Flange, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, and cleaning the flange to remove any buildup that could affect its function. Adhering to the manufacturer’s maintenance schedule can help in identifying potential issues before they become serious problems 8.

Compatibility with Engine Models

Cummins 4B3.9 Engine

The Crankshaft Flange part 3905820 is specifically engineered to fit the Cummins 4B3.9 engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The flange ensures that the crankshaft remains securely attached to the engine block, minimizing the risk of misalignment or failure during operation.

Cummins B4.5 Engine

Similarly, the Crankshaft Flange part 3905820 is also compatible with the Cummins B4.5 engine. This engine variant is recognized for its efficiency and durability, making it a popular choice in various industrial and commercial applications. The flange’s design allows for precise alignment and secure fastening, contributing to the overall stability and longevity of the engine.

Importance of the Crankshaft Flange

The crankshaft flange plays a vital role in maintaining the structural integrity of the engine. By providing a robust connection point, it helps to distribute the forces generated during engine operation evenly across the engine block. This reduces the likelihood of mechanical failure and ensures consistent performance over time 9.

Installation and Maintenance

Proper installation of the Crankshaft Flange part 3905820 is essential to ensure optimal engine performance. Technicians should follow the manufacturer’s guidelines for torque specifications and alignment procedures to avoid any issues during operation. Regular maintenance checks should also be conducted to inspect for any signs of wear or damage, ensuring the flange remains in good condition 10.

Conclusion

The Crankshaft Flange part 3905820 is a critical component for both the Cummins 4B3.9 and B4.5 engines. Its design and functionality are tailored to provide a secure and reliable connection between the crankshaft and engine block, enhancing the overall performance and durability of the engine.

Role of Part 3905820 Crankshaft Flange in Engine Systems

The Part 3905820 Crankshaft Flange is an essential component that interfaces with several key elements within engine systems, ensuring smooth operation and efficiency.

Integration with the Damper

The Crankshaft Flange is designed to connect directly with the damper. This connection is fundamental for absorbing torsional vibrations generated by the engine’s operation. The damper, typically a harmonic balancer, relies on the flange to transmit rotational forces while mitigating vibrations that could otherwise lead to mechanical wear or failure 11.

Connection to the Vibration System

In conjunction with the vibration dampening system, the Crankshaft Flange plays a significant role. By providing a stable mounting point for the damper, it helps in maintaining the balance of the crankshaft. This balance is vital for reducing vibrations that can affect the engine’s performance and longevity. The flange’s precise fit and robust construction ensure that it can handle the dynamic loads without compromising the integrity of the vibration control system 12.

Adapter Compatibility

The Crankshaft Flange also serves as an adapter between the crankshaft and other engine components. Its design allows for the secure attachment of various accessories, such as pulleys and sensors, which are essential for the engine’s operation. The flange’s role as an adapter ensures that these components are aligned correctly, facilitating efficient power transmission and accurate sensor readings 13.

Front Drive Mechanisms

In engines equipped with front-drive mechanisms, the Crankshaft Flange is integral to the drive system. It provides the necessary interface for the front-drive components, ensuring that power is transferred smoothly from the crankshaft to the drive system. This connection is vital for the overall functionality of front-drive engines, as it ensures that the drive components operate in sync with the engine’s rotational speed 14.

In summary, the Part 3905820 Crankshaft Flange is a pivotal component that enhances the performance and reliability of engine systems by facilitating smooth power transmission, reducing vibrations, and ensuring proper alignment of critical components.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Willard W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine (Pearson Education, 2014).

↩ -

Michael Hilgers, Electrical Systems and Mechatronics, Second Edition (Springer Vieweg, 2023).

↩ -

A.J. Martyr, Engine Testing: Theory and Practice: Third Edition (SAE International, 2007).

↩ -

Cummins Inc., Fault Code Troubleshooting Manual (Bulletin Number 5579523).

↩ -

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Willard W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine (Pearson Education, 2014).

↩ -

Michael Hilgers, Electrical Systems and Mechatronics, Second Edition (Springer Vieweg, 2023).

↩ -

A.J. Martyr, Engine Testing: Theory and Practice: Third Edition (SAE International, 2007).

↩ -

Cummins Inc., Fault Code Troubleshooting Manual (Bulletin Number 5579523).

↩ -

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Willard W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine (Pearson Education, 2014).

↩ -

Michael Hilgers, Electrical Systems and Mechatronics, Second Edition (Springer Vieweg, 2023).

↩ -

A.J. Martyr, Engine Testing: Theory and Practice: Third Edition (SAE International, 2007).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.