This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

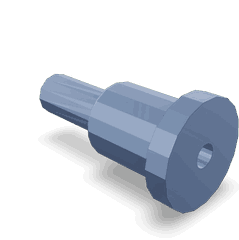

The Cummins 3935744 Idler Shaft is a component designed for use in heavy-duty trucks. It serves a specific function within the engine’s timing system, contributing to the overall efficiency and performance of the vehicle. Understanding its role and significance can provide valuable insights into the maintenance and operation of heavy-duty trucks.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component that supports the rotation of other parts within a system. In the context of a truck’s engine, it helps maintain the proper alignment and tension of the timing belt or chain. This ensures that the engine’s valves open and close at the correct times, which is essential for the engine’s operation 1.

Purpose of the Cummins 3935744 Idler Shaft

The Cummins 3935744 Idler Shaft plays a role in the truck’s engine by supporting the timing system. It maintains the correct tension on the timing belt or chain, which is necessary for the precise operation of the engine’s valves. This component ensures that the valves open and close in sync with the pistons’ movements, contributing to the engine’s overall performance 2.

Key Features

The Cummins 3935744 Idler Shaft is characterized by several features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the rigors of heavy-duty truck operation. The design includes precise machining to ensure smooth operation and longevity. Additionally, it may incorporate features such as integrated bearings or seals to reduce friction and protect against contaminants.

Benefits of Using the Cummins 3935744 Idler Shaft

Using the Cummins 3935744 Idler Shaft can lead to several advantages. It contributes to improved engine efficiency by ensuring that the timing system operates correctly. This can result in reduced wear on other engine components, as the system runs more smoothly. Furthermore, the proper function of the idler shaft enhances the overall performance of the engine, leading to better fuel efficiency and reduced emissions 3.

Installation Considerations

When installing the Cummins 3935744 Idler Shaft, it is important to follow the manufacturer’s guidelines. This may involve using specific tools to ensure proper alignment and tensioning of the timing belt or chain. Correct installation is vital to the component’s performance and the engine’s reliability.

Troubleshooting Common Issues

Idler shafts can encounter issues such as noise, vibration, or failure symptoms. These problems may indicate wear, misalignment, or other issues. Diagnostic steps to address these problems can include inspecting the shaft for signs of wear, checking the alignment and tension of the timing belt or chain, and ensuring that all related components are in good condition.

Maintenance Tips

To ensure the longevity and reliable operation of the Cummins 3935744 Idler Shaft, routine maintenance is recommended. This includes regular inspections for signs of wear or damage, and following the manufacturer’s guidelines for lubrication. Proper maintenance can help prevent issues and ensure that the idler shaft continues to perform its function effectively.

Cummins Overview

Cummins Inc. is a well-established company in the heavy-duty truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a leader in providing solutions for the transportation sector.

Idler Shaft Part 3935744 Compatibility with Cummins Engines

The Idler Shaft part number 3935744, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This component is crucial for maintaining the operational integrity of the engine’s timing system. Here’s how it aligns with various Cummins engines:

6C8.3

The 6C8.3 engine benefits from the Idler Shaft part 3935744, ensuring precise timing and smooth operation of the camshaft. This part is engineered to handle the specific demands of the 6C8.3 model, providing durability and reliability.

ISC CM850 and ISL9 CM2150 SN

Both the ISC CM850 and ISL9 CM2150 SN engines are compatible with the Idler Shaft part 3935744. This compatibility is due to the part’s design, which accommodates the unique requirements of these engines, including their timing mechanisms and camshaft operations.

QSC8.3 CM850 (CM2850) and QSL9 CM850 (CM2850)

The Idler Shaft part 3935744 is also suitable for the QSC8.3 CM850 (CM2850) and QSL9 CM850 (CM2850) engines. These engines share similar design elements, making the idler shaft a versatile component that can be used across multiple models. Its application in these engines ensures consistent performance and longevity.

Role of Part 3935744 Idler Shaft in Engine Systems

The idler shaft, specifically part 3935744, is an integral component in the efficient operation of various engine systems. Its primary function is to maintain proper belt tension and alignment, ensuring smooth and reliable performance of the driven components.

Drive System Integration

In the drive system, the idler shaft plays a significant role by supporting the serpentine belt. It ensures that the belt remains taut and correctly aligned, which is essential for the efficient transfer of power to other engine components. Without adequate tension, the belt could slip, leading to reduced efficiency and potential damage to the drive system.

Water Pump Operation

The water pump is another component where the idler shaft is vital. By keeping the serpentine belt properly tensioned, the idler shaft ensures consistent rotation of the water pump. This consistent rotation is necessary for the effective circulation of coolant throughout the engine, maintaining optimal operating temperatures and preventing overheating.

Fan Support Mechanism

In systems where the fan is belt-driven, the idler shaft assists in maintaining the necessary belt tension for the fan. This ensures that the fan operates smoothly, providing adequate airflow for cooling the engine and other components. Proper fan operation is essential for thermal management within the engine compartment.

Mounting and Stability

The idler shaft is often part of a mounting system that secures various components in place. Its role in maintaining belt tension indirectly contributes to the stability and proper functioning of these mounted components. This is particularly important in high-vibration environments typical of engine operation.

Alternator Function

For the alternator, the idler shaft ensures that the serpentine belt remains in optimal contact with the alternator pulley. This is crucial for the alternator’s ability to generate electricity efficiently, powering the vehicle’s electrical systems and recharging the battery.

Water Pump Drive System

In engines where the water pump is driven by a belt, the idler shaft’s role in maintaining belt tension is indispensable. It ensures that the water pump operates consistently, providing reliable coolant circulation. This is essential for the longevity and performance of the engine, as consistent coolant flow prevents hotspots and reduces the risk of engine damage.

Conclusion

The Cummins 3935744 Idler Shaft is a critical component in the operation of heavy-duty truck engines. Its role in maintaining the proper tension and alignment of the timing belt or chain ensures the precise operation of the engine’s valves, contributing to overall engine performance, fuel efficiency, and reduced emissions. Proper installation, maintenance, and understanding of its function are essential for the reliable operation of Cummins engines.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems, SAE International, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.