The Cummins 3949357 Crankshaft Gear is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the precise timing of engine operations by engaging with the timing chain or belt. This gear is integral to maintaining the synchronization between the crankshaft and camshaft, which is vital for the engine’s performance and efficiency 1.

Basic Concepts of Crankshaft Gear

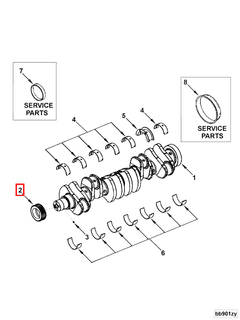

A crankshaft gear is a toothed wheel attached to the crankshaft of an engine. Its function is to transfer rotational motion from the crankshaft to other engine components, such as the camshaft, via the timing chain or belt. This transfer ensures that the engine’s valves open and close in sync with the pistons’ movements, which is fundamental for combustion efficiency and engine operation 2.

Role of the 3949357 Crankshaft Gear in Truck Operation

The 3949357 Crankshaft Gear plays a significant role in the operation of a truck by ensuring that the engine’s timing is accurately maintained. This gear contributes to the engine’s performance by allowing the crankshaft and camshaft to operate in harmony. Proper timing is crucial for the engine’s ability to deliver power efficiently and reliably, directly impacting the truck’s overall performance and fuel efficiency 3.

Key Features of the 3949357 Crankshaft Gear

The Cummins 3949357 Crankshaft Gear is characterized by several key features that enhance its functionality. These include a precise design that ensures a snug fit and smooth operation within the engine. The gear is manufactured from high-quality materials to withstand the rigors of heavy-duty truck operation, offering durability and reliability. Its design specifications are tailored to meet the demanding requirements of Cummins engines, ensuring optimal performance 4.

Benefits of Using the 3949357 Crankshaft Gear

Utilizing the Cummins 3949357 Crankshaft Gear offers several benefits. It contributes to improved engine performance by ensuring accurate timing, which is essential for efficient combustion. The gear’s durable construction enhances the engine’s reliability, reducing the likelihood of timing-related failures. Additionally, its precise design helps maintain engine efficiency, potentially leading to better fuel economy and reduced emissions 1.

Installation and Compatibility

Proper installation of the 3949357 Crankshaft Gear is crucial for ensuring its effective operation. Installation procedures should follow manufacturer guidelines to avoid damage and ensure compatibility with the engine. While specific tools or equipment may be required for installation, adhering to these procedures helps maintain the gear’s integrity and the engine’s performance. Compatibility with various Cummins engine models ensures that this gear can be used across a range of applications, providing versatility for truck operators 2.

Maintenance and Troubleshooting

Maintaining the 3949357 Crankshaft Gear is important for ensuring its longevity and the engine’s performance. Regular inspections should be conducted to check for signs of wear or damage. Lubrication requirements should be met to reduce friction and wear on the gear and its mating surfaces. Common troubleshooting tips include checking for proper alignment and ensuring that the timing chain or belt is in good condition. Addressing issues promptly can prevent more significant problems and maintain the engine’s efficiency 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of various applications, including heavy-duty trucks. Cummins’ focus on quality and innovation ensures that its components, like the 3949357 Crankshaft Gear, contribute to the efficient and reliable operation of engines 4.

Compatibility of the Cummins Crankshaft Gear 3949357

The Cummins Crankshaft Gear 3949357 is designed to fit seamlessly with several engine models, ensuring reliable performance and compatibility. This part is crucial for the proper functioning of the engine, as it interfaces directly with the crankshaft to convert linear motion into rotational motion, which is essential for the engine’s operation.

Compatibility with ISB (Chrysler) Engines

The ISB (Chrysler) engines are part of the Cummins lineup that has been engineered to meet the stringent requirements of the Chrysler Corporation. The Crankshaft Gear 3949357 is compatible with these engines, providing a robust and durable solution for maintaining the engine’s timing and synchronization.

Compatibility with ISB CM850 Engines

The ISB CM850 engines are another variant within the Cummins ISB series, known for their high performance and efficiency. The Crankshaft Gear 3949357 is specifically designed to fit these engines, ensuring precise gear engagement and smooth operation.

Compatibility with QSB5.9 CM850 Engines

The QSB5.9 CM850 engines are part of the Cummins QSB series, which is renowned for its versatility and durability in various applications. The Crankshaft Gear 3949357 is engineered to fit these engines, providing the necessary precision and reliability for optimal engine performance.

Grouping Engines for Compatibility

When considering the compatibility of the Cummins Crankshaft Gear 3949357, it is important to note that it is designed to fit within the ISB and QSB series of engines, specifically those models that include the CM850 designation. This grouping ensures that the gear will work effectively across these engine types, maintaining the engine’s integrity and performance.

Role of Part 3949357 Crankshaft Gear in Engine Systems

The crankshaft gear, identified by part number 3949357, is an integral component in the synchronization and operation of various engine systems. Its primary function is to transfer rotational motion from the crankshaft to other engine components, ensuring the seamless operation of the engine’s mechanical systems.

Interaction with the Cylinder Block

In the cylinder block, the crankshaft gear works in conjunction with the camshaft gear to maintain the precise timing of valve operations. This timing is essential for the intake and exhaust processes, directly influencing the engine’s performance and efficiency. The crankshaft gear’s teeth mesh with those of the camshaft gear, driven by a timing belt or chain, to ensure that the pistons and valves operate in harmony.

Integration in Cylinder Block Kit

When assembling a cylinder block kit, the crankshaft gear plays a significant role in the rebuild process. It ensures that the newly installed components, such as pistons, rings, and bearings, operate in sync with the camshaft and other timing components. Proper installation and alignment of the crankshaft gear are vital for the engine’s smooth operation post-rebuild.

Function in Long Block and Long Block Kit

In a long block, which includes the cylinder block, crankshaft, pistons, and other internal components but excludes ancillary parts like the fuel system and exhaust, the crankshaft gear is essential for integrating the timing system. In a long block kit, where additional components are provided for assembly, the crankshaft gear must be correctly installed to ensure that the engine’s timing is accurate upon completion.

Importance in Short Block and Short Block Kit

Similarly, in a short block, which consists of the cylinder block, crankshaft, pistons, and related components, the crankshaft gear is fundamental for establishing the timing necessary for engine operation. In a short block kit, where components are supplied for assembly, the crankshaft gear’s precise installation ensures that the engine will function correctly once all parts are integrated.

Conclusion

Overall, the crankshaft gear (part 3949357) is a key component in maintaining the timing and synchronization of engine operations across various assembly configurations, from cylinder blocks to long and short block kits. Its proper function and installation are essential for the efficient and reliable performance of the engine.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ ↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ ↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩ ↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.