This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

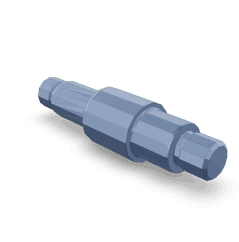

The Cummins 4009433 Idler Shaft is a component designed for use in heavy-duty trucks. It serves a specific function within the truck’s transmission system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the truck’s performance.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component used in various systems to guide or redirect the path of a belt or chain 1. In the context of a truck’s drivetrain, it helps maintain the correct tension and alignment of the belts that drive auxiliary components such as the alternator, water pump, and air conditioning compressor. The idler shaft operates by rotating as the belt moves over it, ensuring smooth and consistent belt operation.

Purpose of the Cummins 4009433 Idler Shaft

The Cummins 4009433 Idler Shaft is integral to the truck’s transmission system. It plays a role in maintaining the proper tension and alignment of the belts that connect various components. By doing so, it ensures that these components operate efficiently and with minimal wear. The idler shaft’s position and design allow it to adjust to the dynamic conditions within the engine compartment, providing stability and reliability to the belt-driven systems.

Key Features

The Cummins 4009433 Idler Shaft is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design includes precision-machined surfaces for smooth belt operation and robust mounting points for secure installation. Additionally, the idler shaft may incorporate features such as sealed bearings to protect against contaminants, further extending its service life 2.

Benefits of Using the Cummins 4009433 Idler Shaft

Incorporating the Cummins 4009433 Idler Shaft into a truck’s transmission system offers several advantages. It contributes to improved efficiency by ensuring optimal belt tension and alignment, which can reduce energy loss and enhance the performance of belt-driven components. Additionally, by maintaining proper belt tension, it helps reduce wear on other components, leading to longer service intervals and lower maintenance costs. The reliability of the truck’s transmission system is also enhanced, as the idler shaft plays a role in preventing belt slippage and related issues 3.

Installation Considerations

Proper installation of the Cummins 4009433 Idler Shaft is crucial for its effective operation. It is important to follow manufacturer guidelines to ensure correct positioning and tensioning of the belts. Special tools may be required for installation, and it is advisable to consult the vehicle’s service manual for specific instructions. Ensuring that the idler shaft is securely mounted and that the belts are correctly tensioned will contribute to the component’s longevity and performance.

Troubleshooting Common Issues

Common problems associated with idler shafts include noise, vibration, or belt slippage. These issues can often be traced back to improper installation, wear, or contamination. Diagnostic steps may include inspecting the idler shaft and belts for signs of wear, ensuring correct belt tension, and checking for proper alignment. Addressing these issues promptly can prevent more serious problems and extend the life of the component.

Maintenance Tips

Routine maintenance is key to ensuring the longevity and optimal performance of the Cummins 4009433 Idler Shaft. Regular inspections should be conducted to check for signs of wear, such as grooves or cracks on the belt contact surface. Belt tension should be verified during routine service intervals, and any adjustments should be made as necessary. Additionally, keeping the area around the idler shaft clean and free of debris can help prevent contamination and extend the component’s service life.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for professionals in the field.

Idler Shaft 4009433 in Cummins Engines

The Idler Shaft 4009433, manufactured by Cummins, is a critical component in several engine models. This part plays a pivotal role in the engine’s operation by maintaining the proper tension of the timing belt or chain, ensuring smooth and efficient engine performance.

K19 Engines

In the K19 engine series, the Idler Shaft 4009433 is integral to the timing mechanism. It works in conjunction with the timing belt or chain to keep the camshaft and crankshaft synchronized, which is essential for the engine’s timing and overall functionality. The design and placement of this idler shaft are specifically engineered to handle the unique demands of the K19 engine, ensuring durability and reliability under various operating conditions.

Grouping of Engines

While the Idler Shaft 4009433 is primarily associated with the K19 engines, it is also compatible with other Cummins engine models that share similar design parameters and operational requirements. These engines often benefit from the precise engineering of the 4009433 idler shaft, which helps maintain optimal engine performance and longevity.

The use of this part across multiple engine models underscores its versatility and importance in Cummins’ engine lineup. By ensuring that the timing belt or chain remains properly tensioned, the 4009433 idler shaft contributes to the overall efficiency and reliability of the engines it supports.

Role of Part 4009433 Idler Shaft in Engine Systems

The 4009433 Idler Shaft is an integral component in various engine systems, facilitating the smooth operation of several key elements.

In systems incorporating a Belt Tensioner, the Idler Shaft assists in maintaining the appropriate tension on the drive belt. This ensures efficient power transmission from the engine to auxiliary components such as the alternator, water pump, and air conditioning compressor. Proper tension is vital for the longevity and performance of these belts, preventing slippage and excessive wear.

When integrated with a Drive System, the Idler Shaft helps in redirecting the path of the drive belt. This redirection is essential for aligning the belt with other pulleys and components, ensuring a consistent and reliable transfer of rotational force. The Idler Shaft’s position and design allow it to absorb vibrations and reduce noise, contributing to a smoother operation of the drive system.

In engine systems equipped with a Fan, the Idler Shaft plays a role in managing the belt that drives the fan. The fan is responsible for cooling the engine by drawing air through the radiator. The Idler Shaft ensures that the fan belt remains taut, allowing the fan to operate efficiently and maintain optimal engine temperature.

Additionally, in systems with an Idler Lever, the Idler Shaft works in conjunction with the lever to adjust the tension of the belt dynamically. The Idler Lever can be manually or automatically adjusted to compensate for belt wear or changes in engine load, ensuring that the belt maintains the correct tension under varying conditions.

Overall, the 4009433 Idler Shaft is a versatile component that enhances the functionality and reliability of engine systems by ensuring proper belt tension and alignment.

Conclusion

The Cummins 4009433 Idler Shaft is a critical component in heavy-duty truck transmission systems and Cummins engines. Its role in maintaining proper belt tension and alignment contributes to the efficiency, reliability, and longevity of the vehicle’s engine and auxiliary systems. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Awari, G. K., Kumbhar, V. S., & Tirpude, R. B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.